Abstract

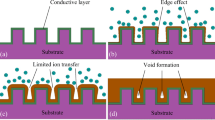

The thickness uniformity and the cross-sectional profiles of electroplated individual nickel microstructures were investigated in given electroplating conditions. The main factors influencing the thickness uniformity of microstructures were discussed. An effective method to overcome the burning problem by increasing the sacrifice seed layer structure is proposed. It is shown that the thickness uniformity and the cross-sectional profiles of the microstructures can be controlled by changing the process conditions. The current crowding observed in patterned specimens is responsible for the saddle shape profile of individual microstructures, while the combination of the current crowding and the cathodic polarizability are believed to be responsible for the abnormal cap-like profile of individual microstructures. A uniform thickness distribution and microstructures with flat profiles were obtained at optimal plating conditions of 8.05 mA/cm2 and 20°C.

Similar content being viewed by others

References

Du LQ, Liu HJ, Qin J, Zhu SM (2007) Study on uniformity of micro-electroformed device. Opt Precision Eng 15:69–75 in chinese

Ehdizadeh S, Dukovic JO, Andricacos PC, Romankiw LT (1992) the influence of lithographic patterning on current distribution: a model for the microfabrication by electrodeposition. J Electrochem Soc 139:78–91. doi:10.1149/1.2069205

Flake J, Solomentsev Y, Cooper J, Cooper K (2003) Wafer-scale profile evolution of electrochemically deposited copper films. J Electrochem Soc 150:C195–C201. doi:10.1149/1.1554723

Green TA, Liew MJ, Roy S (2003) Electrodeposition of gold from a thiosulfate-sulfite bath for microelectronic applications. J Electrochem Soc 150:C104–C110. doi:10.1149/1.1541006

Judy JW, Muller RS, Zappe HH (1995) Magnetic microactuation of polysilicon flexure structures. J Microelectromech Syst 4:162–169. doi:10.1109/84.475542

Luo JK, Chu DP, Flewitt AJ, Spearing SM, Fleck NA, Milne WI (2005) Uniformity control of Ni thin-film microstructures deposited by through-mask plating. J Electrochem Soc 152:C36–C41. doi:10.1149/1.1833320

Qu NS, Chan KC, Zhu D (1997) Surface roughening in pulse current and pulse reverse current electroforming of nickel. Surf Coat Tech 91:220–224. doi:10.1016/S0257-8972(96)03184-2

Ren GJ (2001) Electroplating theory and process. Northeastern University, Shenyang in chinese

Takahashi KM (2000) Electroplating copper onto resistive barrier films. J Electrochem Soc 147:1414–1417. doi:10.1149/1.1393370

Wei ZJ, Wang YY, Wan CC, Huang CH (2000) Study of wetters in nickel electroforming of 3D microstructures. Mater Chem Phys 63:235–239. doi:10.1016/S0254-0584(99)00228-X

Yeh YM, Chen CS, Tsai MH, Shyng YC, Lee SY, Ou KL (2005) Effect of pulse-reverse current on microstructure and properties of electroformed nickel–iron mold insert. Jpn J Appl Phys 44:1086–1090. doi:10.1143/JJAP.44.1086

Zappe S, Baltzer M, Kraus T, Obermeier E (1997) Electrostatically driven linear micro-actuators: FE analysis and fabrication. J Micromech Microeng 7:204–209. doi:10.1088/0960-1317/7/3/033

Acknowledgments

This work has been supported by the National High Technology Research and Development Program of China (863 Program, project No: 2007AA042102) and Key Project of Science Plan of Jilin under code 20060335.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, Jd., Zhang, P., Wu, Yh. et al. Uniformity study of nickel thin-film microstructure deposited by electroplating. Microsyst Technol 15, 505–510 (2009). https://doi.org/10.1007/s00542-008-0754-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-008-0754-5