Abstract

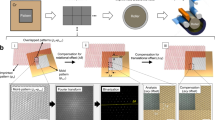

A unique fabrication method for a curved copper micromesh is proposed and demonstrated. A PDMS mold was fabricated using a microcasting process and then used as a flexible mold in copper electroplating. The fabricated copper micromesh was well formed and connected without any cracks within the entire mold area. The experimental results verified that the fabricated features of the copper micromesh accurately followed the shape of the microstructures and the curvature of the PDMS mold. This unique fabrication method provides an alternative means to produce curved or three-dimensional metal microstructures.

Similar content being viewed by others

References

Beckera H, Gärtner C (2000b) Polymer based micro-reactors. Rev Mol Biotechnol 82:89–99

Becker H, Heim U (2000a) Hot embossing as a method for the fabrication of polymer high aspect ratio structures. Sens Actuators A Phys 83:130–135

Evans RC, Douglas P, Winscom CJ (2006) Coordination complexes exhibiting room-temperature phosphorescence: evaluation of their suitability as triplet emitters in organic light emitting diodes. Coord Chem Rev 250:2093–2126

Gale MT, Gimkiewicz C, Obi S, Schnieper M, Söchtig J, Thiele H, Westenhöfer S (2005) Replication technology for optical microsystems. Opt Lasers Eng 43:373–386

Heckele M, Schomburg WK (2004) Review on micro molding of thermoplastic polymers. J Micromech Microeng 14:R1–R14

Ko JS, Yoon HC, Yang H, Pyo HB, Chung KH, Kim SJ, Kim YT (2003) A polymer-based microfluidic device for immunosensing biochips. Lab Chip 3:106–113

Michel B, Bernard A, Bietsch A, Delamarche E, Geissler M, Juncker D, Kind H, Renault JP, Rothuizen H, Schmid H, Winkel PS, Stutz R, Wolf H (2001) Printing meets lithography: soft approaches to high-resolution patterning. IBM J Res Dev 45(5):697–719

Odom TW, Love JC, Wolfe DB, Paul KE, Whitesides GM (2002) Improved pattern transfer in soft lithography using composite stamps. Langmuir 18:5314–5320

Reese C, Roberts M, Ling MM, Bao Z (2004) Organic thin film transistors. Mater Today 7(9):20–27

Rost C, Karga S, Riess W, Loi MA, Murgia M, Muccini M (2004) Light-emitting ambipolar organic heterostructure field-effect transistor. Synth Methods 146:237–241

Sha B, Dimov S, Griffiths C, Packianather MS (2007) Investigation of micro-injection moulding: factors affecting the replication quality. J Mater Process Technol 183:284–296

Sheraw CD, Zhou L, Huang JR, Gundlach DJ, Jackson TN, Kane MG, Hill IG, Hammond MS, Campi J, Greening BK, Francl J, West J (2002) Organic thin-film transistor-driven polymer-dispersed liquid crystal displays on flexible polymeric substrates. Appl Phys Lett 80:1088–1090

Sirringhaus H, Tessler N, Friend RH (1998) Integrated optoelectronic devices based on conjugated polymers. Science 280:1741–1744

Wang Z, Yuan J, Zhang J, Xing R, Yan D, Han Y (2003) Metal transfer printing and its application in organic field-effect transistor fabrication. Adv Mater 15:1009

Xia Y, Whitesides GM (1998) Soft lithography, Angew. Chem Int Ed 37:550–575

Acknolowledgments

This work was supported by the Korea Science and Engineering Foundation(KOSEF) grant funded by the Korea government(MOST) (No. R01-2007-000-11051-0).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jung, S.N., Kang, C.K., Jung, I.D. et al. Fabrication of curved copper micromesh sheets using flexible PDMS molds. Microsyst Technol 14, 829–833 (2008). https://doi.org/10.1007/s00542-008-0599-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-008-0599-y