Abstract

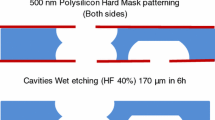

This paper presents the different processing steps of a new generic surface micromachining module for MEMS hermetic packaging at temperatures around 180 °C based on nickel plating and photoresist sacrificial layers. The advantages of thin film caps are the reduced thickness and area consumption and the promise of being a low-cost batch process. Moreover, sealing happens by a reflow technique, giving the freedom of choosing the pressure and atmosphere inside the cavity. Sacrificial etch holes are situated above the device allowing shorter release times compared to the state-of-the-art. With the so-called over-plating process, small etch holes can be created in the membrane without the need of expensive lithography tools. The etch holes in the membrane have been shown to be sufficiently small to block the sealing material to pass through, but still large enough to enable an efficient release.

Similar content being viewed by others

References

Brubaker C, Lindner P and Schaefer C (2002) Wafer level packaging and 3D interconnects for IC technology. In: Proceedings IEEE/SEMI advanced semiconductor manufacturing conference, Boston, pp 212–217

Cheng YT, Hsu WT, Lin L, Nguyen CT, Najafi K (2001) Vacuum-packaging technology using localized aluminium/silicon-to-glass bonding. In: Proceedings 14th international conference on MEMS, Interkalen, Switzerland

Chomas LC et al (2003) Low-cost manufacturing/packaging process for MEMS inertial sensors. In: Proceedings 36th international symposium on microelectronics (IMAPS 2003), Boston, MA, pp 389–401

Hochst A et al (2004) Stable thin film encapsulation of acceleration sensors using polycrystalline silicon as sacrificial and encapsulation layer. Sens Actuators A Phys 114(2–3):355–361

Gallant A, Wood D (2005) Surface micromachined membrane for wafer level packaging. Micromech Microeng 15:547–552

Ko WH, Suminto JT, Yeh GJ (1985) Bonding techniques for microsensors. Micromachining and micropackaging of transducers. Elsevier, Amsterdam, pp 41–61

Liu CH, Lu JM, Fang W (2005) Encapsulation of film bulk acoustic resonator filters using a wafer-level microcap array. Micromech Microeng 15:1433–1438

Mazza E, Abel S, Dual J (1996) Experimental determination of mechanical properties of Ni and Ni–Fe microbars. Microsyst Technol 2:197–202

Partridge A, Rice AE, Kenny TW, Lutz M (2001) A new thin film epitaxial polysilicon for piezoresistive accelerometers. In: Proceedings MEMS 2001, pp 54–59

Rusu C, Jansen H, Gunn R, Witvrouw A (2003) Self-aligned 0-level sealing of MEMS devices by a two layer thin film reflow process. In: Proceedings DTIP of MEMS and MOEMS 2003, pp 245–250

Stahl H et al (2003) Thin film encapsulation of acceleration sensors using polysilicon sacrificial layers. In: Twelfth international conference on solid-state sensors, actuators and microsystems transducers, pp 1899–1902

Stark BH, Najafi K (2004) A low temperature thin film electroplated metal vacuum package. Microelectromech Syst 13(2):147–157

Tilmans HAC, Van de Peer MDJ, Beyne E (2000) The intend reflow sealing technique, a method for fabrication of sealed cavities for MEMS devices. MEMS 9:206–217

Tsuchiya T et al (2001) Polysilicon vibrating gyroscope vacuum encapsulated on-chip micro chamber. Sens Actuators A Phys 90:1–2

Acknowledgments

The authors would like to thank Bert Du Bois for helpful discussions and for SEM analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hellín Rico, R., Celis, JP., Baert, K. et al. A new generic surface micromachining module for MEMS hermetic packaging at temperatures below 200 °C. Microsyst Technol 13, 1451–1456 (2007). https://doi.org/10.1007/s00542-006-0351-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-006-0351-4