Abstract

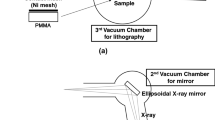

We have investigated and report in this paper the factors influencing the deformation caused by the dependence between the absorbed X-ray energy on the resist and the shape of the absorber on the X-ray mask. Based on the measurement of errors that occurred during the transferring process between the 2-D shape of mask pattern and the resulting wall of the fabricated 3-D structure, we have developed newly useful graphical data on the absorbed X-ray energy, dosage, and shape of a microstructure. As a result, it is being reported as a method for compensation for the deformed shape after the fabrication of a quadruplets-microneedle. We have considered a number of factors affecting the deformation and finally realized that the effect of a dose–depth nonlinear curve is the most possible cause. Without the compensation of the mask design, we could observe the deformed shapes of the sloped sidewall on the exposed structures. Polymethylmethacrylate microneedle structures fabricated by X-ray lithography with an additional plane-pattern to cross-section transfers technique are directly influenced by the absorber on the X-ray mask pattern. The sidewall of the microneedle was improved by changing the mask pattern from a double right-triangular pattern to a double semi-circular pattern, modeled by comparing the results from a mask-pattern and the actual structure.

Similar content being viewed by others

References

Bley P, Mohr J (1994) The LIGA process—a microfabrication technology. FED J 5:1–34

Chou HY, Chang SB, Lin F, Yang CR, Lou R, Kuo WK, Chen CJ, Huang WH (1998) Rapid 3D microstructure fabrication by using excimer laser micromachining with image processing technologies. In: ASPE Annual Proceedings, Indianapolis, p 189

Ehrfeld W, Hessel V, Lowe H, Schulz Ch, Weber L (1999) Materials of LIGA technology. In: Proceedings MST’99, Tokyo, p 105

Ehrfeld W, Lher H (1995) Deep X-ray lithography for the production of three-dimensional microstructures from metals, polymers, and ceramics. Radiat Phys Chem 45:3–340

Feierag G, Ehrfeld W, Lehr H, Schmidt A, Schmidt M (1997) Calculation and experimental determination of the structure transfer accuracy in deep X-ray lithography. J Micromech Microeng, p 323

Khumpuang S, Maeda R, Sugiyama S (2004) Design and fabrication of a coupled microneedle array and insertion guide array for safe penetration through skin. In: Proceedings MHS’03, Nagoya, p 233

Lee CSB, Han S, Mcdonald NC (2000) Single crystal silicon (SCS) XY-stage fabricated by DRIE and IR alignment. In: Proceedings MEMS’00, Miyazaki, p 28

Sugiyama S, Ueno H (2001) Novel shaped microstructures processed by deep X-ray lithography. In: Technical digest of the 2001 international conference on solid state sensors and actuators (transducers’01), pp 1574–1577

Tabata O, Terasoma K, Agawa N, Yamamoto K (1999) Moving mask LIGA (M2LIGA) process for control of side wall inclination. In: Proceedings MEMS’99, Florida, p 252

Ueno H, Sugiyama S (2001) Novel shaped microstructures processed by deep X-ray lithography using plane pattern-cross section transfer technique. In: Proceedings HARMST’01, Baden-baden, p 15

Acknowledgments

The authors would like to thank Mr. Hiroyuki Ikeda, a technician in the SR center, Ritsumeikan University, for his technical assistance and Dr. Hiroshi Ueno for the useful data.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Horade, M., Khumpuang, S., Fujioka, K. et al. Mask design compensation for sloped sidewall structures fabricated by X-ray lithography. Microsyst Technol 13, 215–219 (2007). https://doi.org/10.1007/s00542-006-0219-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-006-0219-7