Abstract

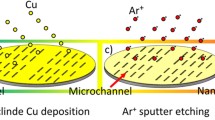

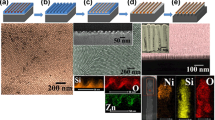

A simple low-cost technique has been developed to fabricate a mold insert for replicating polymeric tapered high aspect ratio microstructures. A backside exposure technique is used to first obtain a tapered sidewall structure as an electroplating mold in SU-8 photoresist on a glass wafer. Nickel electroplating is utilized to form the mold insert. The lowest average surface roughness of the nickel mold insert on the side that interfaces with the glass wafer during electroplating is measured to be 7.02 nm. A novel technique involving use of titanium putty is introduced here to reduce cost and effort required to fabricate the mold insert. Replication of tapered microstructures in polymeric materials utilizing the fabricated mold insert is demonstrated here in polydimethylsiloxane by a direct molding process and in polymethyl methacrylate by hot embossing. The fabrication details for the mold insert are described. Advantages and disadvantages of the use of titanium putty for achieving superior metal surface finish are given.

Similar content being viewed by others

References

Becher EW, Ehrfeld W, Hagmann P, Maner A, Muenchmeyer D (1986) Fabrication of microstructures with high aspect ratio and great structural heights by synchrotron radiation lithography, electroforming and plastic molding (LIGA process). Microelectron Eng 4:35–56

Despont M, Lorenz H, Fahrni N, Brugger J, Renaud P, Vettiger P (1997) High-aspect-ratio, ultrathick, negative-tone near-uv photoresist for MEMS applications. In: Micro Electro Mechanical Systems, 1997, MEMS ‘97, Proceedings IEEE, 10th annual international workshop, 26–30 January 1997, pp. 518–522

Kim K, Park DS, Lu HM, Che W, Kim K, Lee JB, Ahn CH (2004) A tapered hollow metallic microneedle array using backside exposure of SU-8. J Micromech Microeng 14:597–603

Peterman MC, Huie P, Bloom DM, Fishman HA (2003) Building thick photoresist structures from the bottom up. J Micromech Microeng 13:380–382

Turner R, Desta Y, Kelly K, Zhang J, Geiger E, Cortez S, Mancini DC (2003) Tapered LIGA HARMs. J Micromech Microeng 13:367–372

Acknowledgments

The authors acknowledge the assistance of Mr Golden Hwaung and Mr Naga Korivi during fabrication. Any opinions, findings, and conclusions or recommendations expressed here are those of the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, IH., Jin, Y. & Ajmera, P.K. Fabrication of a polymeric tapered HARMs array utilizing a low-cost nickel electroplated mold insert. Microsyst Technol 13, 287–291 (2007). https://doi.org/10.1007/s00542-006-0212-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-006-0212-1