Abstract

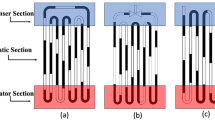

This paper describes the design, fabrication and test of a silicon-based micro combustor, which is a part of a micro power generation system under development. Based on the three-dimensional computational fluid dynamics (CFD) simulation and analysis of different micro combustor design, a hairpin-shape design for air/fuel recirculation channel is adopted. The combustor is fabricated from seven single crystal silicon wafers using deep reactive ion etching (DRIE) process. It has been assembled successfully with gas tubing and thermal couplers for monitoring the exit gas temperature. The effect of mass flow rate on the combustion characteristics is studied experimentally and numerically under several operating conditions. The exhaust gas temperature can reach the range from 870 to 1,100 K. The results indicate that with the increases of the mass flow rate, the combustor exhaust gas temperature increase as well in both experimental and the simulated results. This is due to the heat released in the combustor increases with the fuel/air mass flow rate.

Similar content being viewed by others

References

Deutschmann O (2003) User manual DETCHEM-package

Epstein AH (2003) Millimeter-scale MEMS gas turbine engines. In: Proceeding of ASME Turbo Expo2003 Power for Land, Sea and Air, Atlanta, pp 1–28

Epstein AH, Senturia SD,Anathasuresh G (1997) Power MEMS and microengines. IEEE Transducers In: Proceeding ‘97 Conference, Chicago, pp 753–756

Glassman (1996) Combustion. Academic, California

Hua J, Wu M, Kumar K (2005a) Numerical simulation of the combustion of hydrogen–air mixture in micro-scaled chambers. Part I: fundamental study. Chem Eng Sci 60(13):3497–3506

Hua J, Wu M, Kumar K (2005b) Numerical simulation of the combustion of hydrogen–air mixture in micro-scaled chambers. Part II: CFD analysis for a micro-combustor. Chem Eng Sci 60(13):3507–3515

Isomura K, Tanaka S, Togo S, Kanebako H, Murayama M, Saji N, Sato F, Esashi M (2004) Development of micromachined gas turbine engine for portable power generation. JSME Int J Ser B 47(3):459–464

Linan A, Williams FA (1993) Fundamental aspects of combustion. Oxford University, New York

Mehra A (2000) Development of a high power density combustion system for a silicon micro gas turbine engine. Dissertation, MIT, Cambridge

Tien JH, Stalker RJ (2002) Release of chemical energy by combustion in a supersonic mixing layer of hydrogen and air. Combustion Flame 130:329–348

Acknowledgement

This research is financially supported by the Agency for Science, Technology and Research (A*Star), Singapore, under Project 022-107-0011.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Z.F., Wu, M., Shan, X.C. et al. MEMS-based combustor with hairpin-shape design of gas recirculation channel. Microsyst Technol 12, 993–997 (2006). https://doi.org/10.1007/s00542-006-0125-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-006-0125-z