Abstract

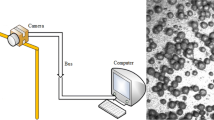

The thermal efficiency for the pelletizing process is intrinsically linked to the diameter and humidity of the iron ore pellets, so that the sensing of the granulometric range in the formation of the pellets becomes essential to the flow of the pelletizing process in the steel industry; this paper presents the assembly of a computer vision system for the detection and segmentation of pellets aiming at the automation of the granulometric measurement, following its formation in the pelletizing disk, using the instance segmentation method to verify whether the particle granulometric distribution (PSD) is adequate for “real-time” applications. The system calculates the normal distribution of the diameter in millimeters, evaluating the normal curve and the standard deviation of the segmented pellets, using a deep neural network based on the You Only Look At CoefficienTs (YOLACT) network, adding speed and precision in the granulometric analysis. In the sample sets, the need for adjustment factors inherent to the pelletizing process became evident. This led to the establishment of the computer vision system, termed the Volumetric Correction Factor (VCF) and Visual Overlay Factor (VOF). The VCF is utilized to estimate the volume of pellets within the pelletizing disk during operation, while the VOF adjusts the millimeter-per-pixel (mpp) ratio. The results of the measurement system proved to be efficient in real-time granulometric measurement.

Similar content being viewed by others

Data availability

Not applicable.

References

Bhuiyan IU, Mouzon J, Forsberg F, Forsmo SPE, Sjödahl M, Hedlund J (2013) Consideration of x-ray microtomography to quantitatively determine the size distribution of bubble cavities in iron ore pellets. Powder Technol 233:312–318. https://doi.org/10.1016/j.powtec.2012.09.012

Weng L (2017) Object detection for dummies part 3: R-CNN family. https://lilianweng.github.io/posts/2017-12-31-object-recognition-part-3/

Andersson T, Thurley MJ (2011) Minimizing profile error when estimating the sieve-size distribution of iron ore pellets using ordinal logistic regression. Powder Technol 206(3):218–226. https://doi.org/10.1016/j.powtec.2010.09.021

Borim J, Freitas R (2009) Controle automático da distribuição granulométrica de pelotas de minério de ferro em uma planta de pelotização. Revista Controle & Instrumentação 148

Zhang Z (2016) Particle overlapping error correction for coal size distribution estimation by image analysis. Int J Miner Process 155:136–139. https://doi.org/10.1016/j.minpro.2016.08.016

Thurley MJ (2009) Automated online measurement of particle size distribution using 3d range data. IFAC Proc Vol 42(23):134–139. https://doi.org/10.3182/20091014-3-cl-4011.00025

Girshick R, Donahue J, Darrell T, Malik J (2014) Rich feature hierarchies for accurate object detection and semantic segmentation. In: 2014 IEEE conference on computer vision and pattern recognition, pp. 580–587. https://doi.org/10.1109/CVPR.2014.81

Girshick R (2015) Fast r-cnn. In: 2015 IEEE international conference on computer vision (ICCV), pp. 1440–1448. https://doi.org/10.1109/ICCV.2015.169

Ren S, He K, Girshick RB, Sun J (2015) Faster R-CNN: towards real-time object detection with region proposal networks. CoRR abs/1506.01497 1506.01497

Shelhamer E, Long J, Darrell T (2017) Fully convolutional networks for semantic segmentation. IEEE Trans Pattern Anal Mach Intell 39(4):640–651. https://doi.org/10.1109/tpami.2016.2572683

He K, Gkioxari G, Dollar P, Girshick R (2017) Mask r-CNN. In: 2017 IEEE international conference on computer vision (ICCV). IEEE, Venice, Italy (2017). https://doi.org/10.1109/iccv.2017.322

Bolya D, Zhou C, Xiao F, Lee YJ (2019) YOLACT: Real-time instance segmentation. In: 2019 IEEE/CVF international conference on computer vision (ICCV). IEEE, Seoul, Korea https://doi.org/10.1109/iccv.2019.00925

Bolya D, Zhou C, Xiao F, Lee YJ (2019) Yolact: Real-time instance segmentation. In: ICCV

Lin T-Y, Maire M, Belongie S, Hays J, Perona P, Ramanan D, Dollár P, Zitnick CL (2014) Microsoft coco: Common objects in context. In: Proceedings of the IEEE Conference on computer vision and pattern recognition (CVPR), pp. 740–747

Pan SJ, Yang Q (2010) A survey on transfer learning. IEEE Trans Knowl Data Eng 22(10):1345–1359. https://doi.org/10.1109/TKDE.2009.191

Wada K (2020) Labelme: Image Polygonal Annotation with Python. https://doi.org/10.5281/zenodo.5711226. https://github.com/wkentaro/labelme

Padilla R, Netto SL, Da Silva EA (2020) A survey on performance metrics for object-detection algorithms. In: 2020 International Conference on Systems, Signals and Image Processing (IWSSIP), pp. 237–242. IEEE

National Instruments: Calculating camera sensor resolution and lens focal length (2020). https://www.ni.com/en-nz/support/documentation/supplemental/%0A18/calculating-camera-sensor-resolution-and-lens-focal-length.html Accessed 2020-11-05

Passos LAS, Moreira JL, Jorge A, Cavalcante MVS (2014) Melhoria no desempenho do processo de produçao de pelotas de minério de ferro em discos de pelotizaçao pela utilizaçao de sistemas otimizantes com lógica nebulosa

Acknowledgments

The authors acknowledge the scientific and technical support of the Federal Institute of Espirito Santo and the cooperation of Vale.

Author information

Authors and Affiliations

Contributions

C.M.S., M.A.C., and G.A. were involved in conceptualization, methodology, software, and visualization. C.M.S., R.A., M.A.C., and G.A. were involved in validation, verification, formal analysis, investigation, and data curation. C.V., C.M.S., R.A., M.A.C., and G.A. helped with writing—original paper. C.V., C.M.V., M.A.C., and G.A. contributed to writing—review and editing. M.A.C. and G.A. were involved in project administration. M.A.C. and G.A.s helped with funding.

Corresponding author

Ethics declarations

Conflict of interest

Not applicable.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Publisher's Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Santos, C.M.C.V., de Almeida, R., Valadao, C.T. et al. Iron ore pellets measurement using deep learning based on YOLACT. Neural Comput & Applic (2024). https://doi.org/10.1007/s00521-024-09832-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00521-024-09832-6