Abstract

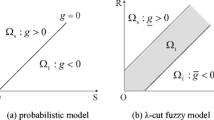

In this study, inclined broken roughness is experimentally investigated to enhance the thermohydraulic performance of solar air heaters. Current article focuses on a fuzzy-based structure as a substitution method for predicting the thermohydraulic performance. A separated fuzzy inference system for each smooth and roughened plate along with an integrated one designed for both plates was selected as the strategy of modeling. In addition, utilizing temperature and velocity features with their generality in all solar air heaters were suggested as a cutting-edge solution to dominate complexity restrictions of geometrical roughness parameters. Throughout the experiments, triangular membership functions obtained better agreement with experimental data than Gaussian functions except for the friction factor of the roughened plate in the separated method. Sugeno structure demonstrated better forecasting ability than Mamdani. Additionally, Nusselt number showed better applicability in being predicted more easily by the considered fuzzy structures rather than the friction factor. Moreover, the system constructed based on the Gaussian membership function showed higher accuracy in forecasting the roughened plate parameters. The least mean square error of the separated method for the Nusselt number and the friction factor of the smooth plate were 2.5477 × 10−04 and 8.1115 × 10−04, respectively. Furthermore, these values were equal to 2.0218 × 10−04 and 7.5150 × 10−04, for the Nusselt number and friction factor of the roughened plate, respectively. Having considered the thermohydraulic performance, the least mean square error of the separated method was equal to 8.6255 × 10-04. The obtained results approved that the fuzzy method is a significantly efficient method for anticipating the parameters of solar air heaters.

Similar content being viewed by others

Abbreviations

- A duct :

-

Cross-sectional area of duct (Aduct = W × H), m2

- A p :

-

Surface area of the collector absorber plate, \({\text{m}}^{2}\)

- A pipe :

-

Cross-sectional area of the pipe, \({\text{m}}^{2}\)

- L :

-

Length of the test section, m

- D h :

-

The equivalent diameter of the air passage = 2WH/(W + H), m

- W :

-

Duct width, m

- H :

-

Duct height, m

- α :

-

Angle of attack, degree

- g :

-

Gap width, m

- d :

-

Center distance of the gap from the side of the duct, m

- P :

-

Pitch of the rib, m

- b :

-

Width of the rib, m

- e :

-

Roughness height, m

- g/e :

-

Relative gap width

- e/D h :

-

Relative roughness height, dimensionless

- P/e :

-

Relative roughness pitch, dimensionless

- d/W :

-

Relative gap position, dimensionless

- W/H :

-

Duct aspect ratio

- T i :

-

Inlet temperature of the air, K

- T o :

-

Outlet temperature of the air, K

- \(\overline{T}_{p}\) :

-

Mean temperature of the absorber plate, K

- \(\overline{T}_{f}\) :

-

Bulk mean temperature of the air through the duct, K

- \(c_{p}\) :

-

Specific heat of air at constant pressure, kJ kg−1 K−1

- μ :

-

Viscosity, kg m−1 s−1

- ν :

-

Kinematic viscosity, m2 s−1

- k :

-

Thermal conductivity of air, W m−1 K−1

- V pipe :

-

Velocity of air through the pipe, m s−1

- V test section :

-

Velocity of air through the test section, m s−1

- Re:

-

Reynolds number

- \(\overline{f}\) :

-

Experimental friction factor

- h L :

-

Heat transfer coefficient through the test section, W m−2 K

- NuL :

-

Nusselt number through the test section

- Δ P :

-

Pressure drop through the test section of the absorber plate, Pa

- ρ pipe :

-

Density of air through the pipe, kg m−3

- ρ test section :

-

Density of air through the test section, kg m−3

- \(\overline{{{\text{Nu}}}}_{r}\) :

-

Average Nusselt number of roughened duct

- \(\overline{{{\text{Nu}}}}_{s}\) :

-

Average Nusselt number of smooth duct

- \(\overline{f}_{r}\) :

-

Average friction factor of roughened duct

- \(\overline{f}_{s}\) :

-

Average friction factor of smooth duct

- \(\dot{m}\) :

-

Mass flow rate, Kg s−1

- \(\dot{Q}\) :

-

Useful heat gain, W

- η :

-

Thermohydraulic performance

- N :

-

Number of data points

- X :

-

Set

- a,b,c :

-

Scalar parameters of triangular membership function

- A :

-

Fuzzy set

- μ A (x) :

-

Membership function

- σ :

-

Variance of the Gaussian membership function

- c :

-

Average of the Gaussian membership function

- \(A_{{nL_{n} }}\) :

-

Fuzzy set for the xn variable

- e i :

-

Error

- a i :

-

Actual data

- p i :

-

Predicted data

- X normilized :

-

Normalized variable

- X min :

-

Minimum input variable

- X max :

-

Maximum input variable

- MSE:

-

Mean square error

- MRE:

-

Mean relative error

References

Saini RP, Singal SK (2007) A review on roughness geometry used in solar air heaters. Sol Energy 81:1340–1350. https://doi.org/10.1016/j.solener.2007.01.017

Bhushan B, Singh R (2010) A review on methodology of artificial roughness used in duct of solar air heaters. Energy 35:202–212. https://doi.org/10.1016/j.energy.2009.09.010

Gawande VB, Dhoble AS, Zodpe DB, Chamoli S (2016) Experimental and CFD-based thermal performance prediction of solar air heater provided with right-angle triangular rib as artificial roughness. J Braz Soc Mech Sci Eng 38:551–579. https://doi.org/10.1007/s40430-015-0391-8

Hans VS, Saini RPP, Saini JSS (2009) Performance of artificially roughened solar air heaters—a review. Renew Sustain Energy Rev 13:1854–1869. https://doi.org/10.1016/j.rser.2009.01.030

Ozgen F, Esen M, Esen H (2009) Experimental investigation of thermal performance of a double-flow solar air heater having aluminium cans. Renew Energy 34:2391–2398. https://doi.org/10.1016/J.RENENE.2009.03.029

Gawande VB, Dhoble AS, Zodpe DB, Chamoli S (2016) Experimental and CFD investigation of convection heat transfer in solar air heater with reverse L-shaped ribs. Sol Energy 131:275–295. https://doi.org/10.1016/j.solener.2016.02.040

Jaurker AR, Saini JS, Gandhi BK (2006) Heat transfer and friction characteristics of rectangular solar air heater duct using rib-grooved artificial roughness. Sol Energy 80:895–907. https://doi.org/10.1016/j.solener.2005.08.006

Saini RP, Verma J (2008) Heat transfer and friction factor correlations for a duct having dimple-shape artificial roughness for solar air heaters. Energy 33:1277–1287. https://doi.org/10.1016/J.ENERGY.2008.02.017

Aharwal KR, Gandhi BK, Saini JSS et al (2009) Heat transfer and friction characteristics of solar air heater ducts having integral inclined discrete ribs on absorber plate. Int J Heat Mass Transf 52:5970–5977. https://doi.org/10.1016/j.ijheatmasstransfer.2009.05.032

RahmatiAidinlou H, Nikbakht AM (2016) Heat flux: thermohydraulic investigation of solar air heaters used in agro-industrial applications. Heat Mass Transf. https://doi.org/10.1007/s00231-016-1864-8

Webb RL, Eckert ERG (1972) Application of rough surfaces to heat exchanger design. Int J Heat Mass Transf 15:1647–1658. https://doi.org/10.1016/0017-9310(72)90095-6

Nikuradse J (1950) Laws of flow in rough pipes. https://ntrs.nasa.gov/citations/19930093938

Dipprey DF, Sabersky RH (1963) Heat and momentum transfer in smooth and rough tubes at various prandtl numbers. Int J Heat Mass Transf 6:329–353. https://doi.org/10.1016/0017-9310(63)90097-8

Aharwal KR, Gandhi BK, Saini JS (2008) Experimental investigation on heat-transfer enhancement due to a gap in an inclined continuous rib arrangement in a rectangular duct of solar air heater. Renew Energy 33:585–596. https://doi.org/10.1016/j.renene.2007.03.023

Gawande VB, Dhoble AS, Zodpe DB, Chamoli S (2016) A review of CFD methodology used in literature for predicting thermo-hydraulic performance of a roughened solar air heater. Renew Sustain Energy Rev 54:550–605

Chamoli S, Yu P, Kumar A (2016) Multi-response optimization of geometric and flow parameters in a heat exchanger tube with perforated disk inserts by Taguchi grey relational analysis. Appl Therm Eng 103:1339–1350. https://doi.org/10.1016/j.applthermaleng.2016.04.166

Chamoli S (2015) Preference selection index approach for optimization of V down perforated baffled roughened rectangular channel. Energy 93:1418–1425. https://doi.org/10.1016/j.energy.2015.09.125

Kalogirou SA (2001) Artificial neural networks in renewable energy systems applications: a review. Renew Sustain Energy Rev 5:373–401. https://doi.org/10.1016/S1364-0321(01)00006-5

Karami A, Rezaei E, Shahhosseni M, Aghakhani M (2012) Fuzzy logic to predict the heat transfer in an air cooler equipped with different tube inserts. Int J Therm Sci 53:141–147. https://doi.org/10.1016/J.IJTHERMALSCI.2011.10.016

Karami A, Rezaei E, Shahhosseni M et al (2011) Fuzzy logic modeling of heat transfer in an air cooler equipped with butterfly insert. Int J Model Optim 53:258–262. https://doi.org/10.7763/IJMO.2011.V1.45

Yousefi T, Karami A, Rezaei E, Ebrahimi S (2012) Fuzzy modeling of the forced convection heat transfer from a V-shaped plate exposed to an air slot jet. Heat Transf Res 41:430–443. https://doi.org/10.1002/htj.21009

Esen H, Ozgen F, Esen M, Sengur A (2009) Modelling of a new solar air heater through least-squares support vector machines. Expert Syst Appl 36:10673–10682. https://doi.org/10.1016/j.eswa.2009.02.045

Wang G, Luo Z, Zhu L et al (2012) Fuzzy estimation for temperature distribution of furnace inner surface. Int J Therm Sci 51:84–90. https://doi.org/10.1016/J.IJTHERMALSCI.2011.07.015

Krzywanski J, Nowak W (2016) Modeling of bed-to-wall heat transfer coefficient in a large-scale CFBC by fuzzy logic approach. Int J Heat Mass Transf 94:327–334. https://doi.org/10.1016/J.IJHEATMASSTRANSFER.2015.11.038

Nadian MH, Abbaspour-Fard MH, Martynenko A, Golzarian MR (2017) An intelligent integrated control of hybrid hot air-infrared dryer based on fuzzy logic and computer vision system. Comput Electron Agric 137:138–149. https://doi.org/10.1016/J.COMPAG.2017.04.001

Kang C-S, Hyun C-H, Park M (2015) Fuzzy logic-based advanced on–off control for thermal comfort in residential buildings. Appl Energy 155:270–283. https://doi.org/10.1016/J.APENERGY.2015.05.119

Selimefendigil F, Öztop HF (2012) Fuzzy-based estimation of mixed convection heat transfer in a square cavity in the presence of an adiabatic inclined fin. Int Commun Heat Mass Transf 39:1639–1646. https://doi.org/10.1016/J.ICHEATMASSTRANSFER.2012.10.006

Ben Ali R, Bouadila S, Mami A (2018) Development of a Fuzzy Logic Controller applied to an agricultural greenhouse experimentally validated. Appl Therm Eng 141:798–810. https://doi.org/10.1016/J.APPLTHERMALENG.2018.06.014

Debnath S, Reddy J, Jagadish DB (2019) An expert system-based modeling and optimization of corrugated plate solar air collector for North Eastern India. J Braz Soc Mech Sci Eng 417(41):1–18. https://doi.org/10.1007/S40430-019-1782-Z

Dadhich M, Prajapati OS (2021) Investigation of heat transfer performance of alumina nanofluid flowing in the horizontal tube using fuzzy logic rules. Energy Sources Part A Recovery Util Environ Effic. https://doi.org/10.1080/155670362021.1901801

Ambigai R, Prabhu S (2021) Fuzzy logic algorithm-based optimization of heat transfer and thermal conductivity behaviour of Al–Si 3 N 4 Nano and Al–Gr–Si 3 N 4 hybrid composite. J Therm Anal Calorim 2021:1–13. https://doi.org/10.1007/S10973-021-10799-Y

ASHRAE Standard 93–2010 (2010) Methods of Testing to Determine the Thermal Performance of Solar Collectors (ANSI approved). 1–42

MATLAB and Statistics Toolbox Release (2016) Fuzzy logic toolbox user’s guide. The MathWorks Inc, Natick, Massachusetts, United States

Aidinlou HR, Nikbakht AM (2017) Intelligent modeling of thermohydraulic behavior in solar air heaters with artificial neural networks. Neural Comput Appl. https://doi.org/10.1007/s00521-017-3269-0

Jahedi G, Ardehali MM (2011) Genetic algorithm-based fuzzy-PID control methodologies for enhancement of energy efficiency of a dynamic energy system. Energy Convers Manag 52:725–732. https://doi.org/10.1016/J.ENCONMAN.2010.07.051

Citakoglu H (2015) Comparison of artificial intelligence techniques via empirical equations for prediction of solar radiation. Comput Electron Agric 118:28–37. https://doi.org/10.1016/J.COMPAG.2015.08.020

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We confirm on not having any conflict of interest with this publication and not having received any financial support for this manuscript which may have affected the results.

Ethical approval

Also, we confirm that all the named authors have read and approved the manuscript, and there is no one involved in the manuscript not being listed in the authorship. Additionally, we confirm that the order of authors in this work is confirmed by all authors. We confirm that we have given due consideration to protect the intellectual property associated with this manuscript and that there are no obstacles for publishing which include the time of publication with respect to the intellectual property. We understand that the “Corresponding author” is the main contact for the editorial procedure (including Editorial Manager and direct communications with the office). He is responsible for communicating with other authors about progress as well as submissions of revisions and final approval of proofs. We confirm that we provide the following correct email address to contact the corresponding author which is accessible for accepting emails aydenlou18@itu.edu.tr.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rahmati Aidinlou, H., Nikbakht, A.M. Fuzzy-based modeling of thermohydraulic aspect of solar air heater roughened with inclined broken roughness. Neural Comput & Applic 34, 2393–2412 (2022). https://doi.org/10.1007/s00521-021-06547-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-021-06547-w