Abstract

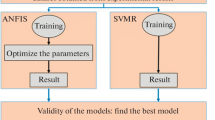

In the present study, an adaptive neuro-fuzzy inference system (ANFIS) model has been used for predicting the corrosion resistance of AA6061-T4 alloy coated with micro-/nano-hydroxyapatite (HA) powders by sol–gel technique. The input parameters of the model consist of the HA powder size (micro-/nanoscale, 35 μm/20 nm), coating thickness (30, 60 and 85 μm) and potential values, while the output parameter is corrosion current density. The performance of proposed ANFIS model was tested on the potentiodynamic polarization scanning (PDS) curves by comparing experimental and the theoretical results of the coatings. The results showed that the generated PDS curves of the coatings are in definitely acceptable levels with obtained results in our experimental reference study. Then, the combined effect of arbitrary selected coating thickness and HA powder size on corrosion behaviour of the coatings was also predicted by trained ANFIS model without using any experimental data. And finally, the predicted results for the arbitrary selected coating thicknesses were compared by validation tests. The results showed that the ANFIS has potential to be used in industrial applications of biomedical implant materials coated with HA without performing any experiments after detailed systematic studies in the near future.

Similar content being viewed by others

References

VisionGain (2015) The global medical devices market will reach $398.0 bn in 2017

Dikici B, Esen Z, Duygulu O, (Koc) SG (2015) Corrosion of metallic biomaterials. Adv Met Biomater Tissues Mater Biol React. doi:10.1007/978-3-662-46836-4

Aksakal B, Gavgali M, Dikici B (2009) The effect of coating thickness on corrosion resistance of hydroxyapatite coated Ti6Al4V and 316L SS ımplants. J Mater Eng Perform 19:894–899. doi:10.1007/s11665-009-9559-7

Sonmez S, Aksakal B, Dikici B (2012) Corrosion protection of AA6061-T4 alloy by sol–gel derived micro and nano-scale hydroxyapatite (HA) coating. J Sol-Gel Sci Technol 63:510–518. doi:10.1007/s10971-012-2813-8

Tait WS (1995) An introduction to electrochemical corrosion testing for practicing engineers and scientists. Prog Org Coat 26:73–74. doi:10.1016/0300-9440(95)90005-5

Singh G, Singh H, Sidhu B (2013) The effect of CaP concentration on corrosion behavior of plasma sprayed hydroxyapatite coating on titanium in simulated body fluid. J Biomim Biomater Tissue Eng 18:1–6. doi:10.4172/1662-100X.1000103

Mohammed MT, Khan ZA, Siddiquee AN (2014) Surface modifications of titanium materials for developing corrosion behavior in human body environment: a review. Proc Mater Sci 6:1610–1618. doi:10.1016/j.mspro.2014.07.144

(2006) Standard test method for conducting cyclic potentiodynamic polarization measurements to determine the corrosion susceptibility of small ımplant devices

Jang JSR (1993) ANFIS: adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cybern 23:665–685. doi:10.1109/21.256541

Culliere T, Titli A, Corrieu JM (1995) Neuro-fuzzy modeling of nonlinear systems for control purposes. In: International Joint Conference of the Fourth IEEE International Conference on Fuzzy Systems and the Second international fuzzy engineering symposium, Proceedings of 1995 IEEE International. IEEE, pp 2009–2016

Türkmen I, Güney K (2005) Computation of association probabilities for single target tracking with the use of adaptive neuro-fuzzy inference system. Turk J Electr Eng Comput Sci 13:105–118

Khoshnevisan B, Rafiee S, Omid M, Mousazadeh H (2014) Development of an intelligent system based on ANFIS for predicting wheat grain yield on the basis of energy inputs. Inf Process Agric 1:14–22. doi:10.1016/j.inpa.2014.04.001

Ghiasi MM, Arabloo M, Mohammadi AH, Barghi T (2016) Application of ANFIS soft computing technique in modeling the CO2 capture with MEA, DEA, and TEA aqueous solutions. Int J Greenh Gas Control 49:47–54. doi:10.1016/j.ijggc.2016.02.015

Jiang H, Kwong CK, Siu KWM, Liu Y (2015) Rough set and PSO-based ANFIS approaches to modeling customer satisfaction for affective product design. Adv Eng Inform 29:727–738. doi:10.1016/j.aei.2015.07.005

Piri J, Kisi O (2015) Modelling solar radiation reached to the Earth using ANFIS, NN-ARX, and empirical models (Case studies: Zahedan and Bojnurd stations). J Atmos Sol Terr Phys 123:39–47. doi:10.1016/j.jastp.2014.12.006

Jang JR, Sun C-T, Mizutani E (1997) Neuro-fuzzy and soft computing. Prentice-Hall Inc, USA

Jang J-SR, Sun Chuen-Tsai (1995) Neuro-fuzzy modeling and control. Proc IEEE 83:378–406. doi:10.1109/5.364486

Amirkhani S, Nasirivatan S, Kasaeian AB, Hajinezhad A (2015) ANN and ANFIS models to predict the performance of solar chimney power plants. Renew Energy 83:597–607. doi:10.1016/j.renene.2015.04.072

Noshadi I, Salahi A, Hemmati M et al (2013) Experimental and ANFIS modeling for fouling analysis of oily wastewater treatment using ultrafiltration. Asia-Pac J Chem Eng 8:527–538. doi:10.1002/apj.1691

Khorami MT, Chelgani SC, Hower JC, Jorjani E (2011) Studies of relationships between Free Swelling Index (FSI) and coal quality by regression and adaptive neuro fuzzy inference system. Int J Coal Geol 85:65–71. doi:10.1016/j.coal.2010.09.011

Abdulshahed A, Longstaff A, Fletcher S, Myers A (2013) Comparative study of ANN and ANFIS prediction models for thermal error compensation on CNC machine tools. In: Proceedings of 10th international conference and exhibition on Laser Metrology, Machine Tool, CMM and Robot Performance (LAMDAMAP’13)

Alimam H, Hinnawi M, Pradhan P, Alkassar Y (2016) Tribology in industry ANN & ANFIS models for prediction of abrasive wear of 3105 aluminium alloy with polyurethane coating. Tribol Ind 38:221–228

Mareci D, Suditu GD, Chelariu R et al (2016) Prediction of corrosion resistance of some dental metallic materials applying artificial neural networks. Mater Corros. doi:10.1002/maco.201608848

Sohrabpoor H (2016) Analysis of laser powder deposition parameters: ANFIS modeling and ICA optimization. Opt Int J Light Electron Opt 127:4031–4038. doi:10.1016/j.ijleo.2016.01.070

Lin C, Yen S, Su C (2016) Measurement and optimization of atmospheric plasma sprayed CoMoCrSi coatings parameters on Ti-6Al-4V substrates affecting microstructural and properties using hybrid abductor induction mechanism. Measurement 94:157–167. doi:10.1016/j.measurement.2016.07.077

Dimitriev Y, Ivanova Y, Iordanova R (2008) History of sol–gel science and technology. Iordanova J Univ Chem Technol Metall 43:181–192. doi:10.1002/chin.200912249

Nené NR, Vieira A, Marques AC et al (2006) Analysis of sol–gel silica–titania films doped with Ag and Er using artificial neural networks. Nucl Instrum Methods Phys Res Sect B Beam Interact Mater Atoms 249:804–807. doi:10.1016/j.nimb.2006.03.144

Yücel A, Güneri AF (2010) Application of adaptive neuro fuzzy inference system to supplier selection problem. J Eng Nat Sci 28:224–234

Galvele JR (2005) Tafel’s law in pitting corrosion and crevice corrosion susceptibility. Corros Sci 47:3053–3067. doi:10.1016/j.corsci.2005.05.043

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Tuntas, R., Dikici, B. An ANFIS model to prediction of corrosion resistance of coated implant materials. Neural Comput & Applic 28, 3617–3627 (2017). https://doi.org/10.1007/s00521-017-3103-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-017-3103-8