Abstract

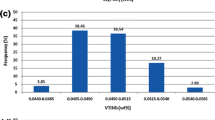

The paper presents some results of the research connected with the development of new approach based on the artificial neural network (ANN) of predicting the ultimate tensile strength of the API X70 steels after thermomechanical treatment. The independent variables in the model are chemical compositions (carbon equivalent), based upon the International Institute of Welding equation (CEIIW), the carbon equivalent, based upon the chemical portion of the Ito-Bessyo carbon equivalent equation (CEPcm), the sum of the niobium, vanadium and titanium concentrations (VTiNb), the sum of the niobium and vanadium concentrations (NbV), the sum of the chromium, molybdenum, nickel and copper concentrations (CrMoNiCu), Charpy impact energy at −10 °C (CVN) and yield strength at 0.005 offset (YS). For purpose of constructing these models, 104 different data were gathered from the experimental results. The data used in the ANN model is arranged in a format of seven input parameters that cover the chemical compositions, yield stress and Charpy impact energy, and output parameter which is ultimate tensile strength. In this model, the training, validation and testing results in the ANN have shown strong potential for prediction of relations between chemical compositions and mechanical properties of API X70 steels.

Similar content being viewed by others

References

Zhao M-C, Yang K, Shan Y (2002) The effects of thermo-mechanical control process on microstructures and mechanical properties of a commercial pipeline steel. Mater Sci Eng A 335:14–20

Bott IS, Souza LFG, Teixeira JCG, Rios PR (2005) High-strength steel development for pipelines: a Brazilian perspective. Metall Mater Trans A 36A:443–454

Hillenbrand IHG, Graf IM, Kalwa IC (2001) Development and production of high strength pipeline steels. In: Proceedings of the conference niobium 2001, Orlando, FL, USA

Takahashi A, Iino M (1996) Thermo-mechanical control process as a tool to grain-refine the low manganese containing steel for sour service line pipe. ISIJ Int 36(2):235–240

Takahashi A, Iino M (1996) Microstructural refinement by Cu addition and its effect on strengthening and toughening of sour service line pipe steels. ISIJ Int 36(2):241–245

Takahashi A, Ogawa H (1996) Influence of microhardness and inclusion on stress oriented hydrogen induced cracking of line pipe steels. ISIJ Int 36(2):334–340

Zhao M-C, Yang K (2005) Strengthening and improvement of sulfide stress cracking resistance in acicular ferrite pipeline steels by nano-sized carbonitrides. Scripta Mater 52:881–886

Contreras A, Albiter A, Salazar M, Perez R (2005) Slow strain rate corrosion and fracture characteristics of X-52 and X-70 pipeline steels. Mater Sci Eng A 407:45–52

Kim YM, Kim SK, Lim YJ, Kim NJ (2002) Effect of microstructure on the yield ratio and low temperature toughness of linepipe steels. ISIJ Int 42(12):1571–1577

Zhong Y, Xiao F, Zhang J, Shan Y, Wang W, Yang K (2006) In situ TEM study of the effect of M/A films at grain boundaries on crack propagation in an ultra-fine acicular ferrite pipeline steel. Acta Mater 54:435–443

Junhua K, Lin Z, Bin G, Pinghe L, Aihua W, Changsheng X (2004) Influence of Mo content on microstructure and mechanical properties of high strength pipeline steel. Mater Des 25:723–728

Lee WB, Hong SG, Park CG, Kim KH, Park SH (2000) Influence of Mo on precipitation hardening in hot rolled HSLA steels containing Nb. Scripta Mater 43:319–324

Sun W, Lu C, Tieu AK, Jiang Z, Liu X, Wang G (2002) Influence of Nb, V and Ti on peak strain of deformed austenite in Mo-based micro-alloyed steels. Mater Process Technol 125–126:72–76

Xiao FR, Liao B, Shan YY, Qiao GY, Zhang Y, Zhang C, Yang K (2006) Challenge of mechanical properties of an acicular ferrite pipeline steel. Mater Sci Eng A 431:41–52

Shanmugam S, Ramisetti NK, Misra RDK, Hartmann J, Jansto SG (2008) Microstructure and high strength–toughness combination of a new 700MPa Nb-microalloyed pipeline steel. Mater Sci Eng A 478:26–37

Khalaj G, Khoeini M, Khakian-Qomi M (2012) ANN-based prediction of ferrite fraction in continuous cooling of microalloyed steels. Neural Comput Appl. doi:10.1007/s00521-012-0992-4

Tugrul O, Yigit K (2005) Predictive modeling of surface roughness and tool wear in hard turning using regression and neural networks. Int J Mach Tools Manuf 45:467–479

Fredj NB, Amamou R (2006) Ground surface roughness prediction based upon experimental design and neural network models. Int J Adv Manuf Technol 31:24–36

Brahme A, Winning M, Raabe D (2009) Prediction of cold rolling textures of steels using an artificial neural network. Comput Mater Sci 46:800–804

Nazari A (2011) Application of artificial neural networks for analytical modeling of Charpy impact energy of functionally graded steels. Neural Comput Appl. doi:10.1007/s00521-011-0761-9

Nazari A, Milani AA, Zakeri M (2011) Modeling Ductile to brittle transition temperature of functionally graded steels by artificial neural networks. Comput Mater Sci 50:2028–2037

Nazari A, Sedghi A, Didehvar N (2011) Modeling impact resistance of aluminum-epoxy laminated composites by artificial neural networks. J Compos Mater. doi:10.1177/0021998311421222

Nazari A (2011) Microhardness profile prediction of functionally graded steels by artificial neural networks. Int J Damage Mech. doi:10.1177/1056789511432653

Trzaska J, Dobrzanski LA (2005) Application of neural networks for designing the chemical composition of steel with the assumed hardness after cooling from the austenitising temperature. J Mater Process Technol 164–165:1637–1643

Monajati H, Asefi D, Parsapour A, Abbasi S (2010) Analysis of the effects of processing parameters on mechanical properties and formability of cold rolled low carbon steel sheets using neural networks. Comput Mater Sci 49:876–881

Parthiban T, Ravi R, Parthiban GT, Srinivasan S, Ramakrishnan KR, Raghavan M (2005) Neural network analysis for corrosion of steel in concrete. Corros Sci 47:1625–1642

Rolich T, Rezic I, Curkovic L (2010) Estimation of steel guitar strings corrosion by artificial neural network. Corros Sci 52:996–1002

Mukherjee M, Singh SB (2009) Artificial neural network: some applications in physical metallurgy of steels. Mater Manuf Process 24:198–208

Bhadeshia HKDH, Dimitriu RC, Forsik S, Pak JH, Ryu JH (2009) On the performance of neural networks in materials science. Mater Sci Technol 25:504–510

Mukherjee A, Biswas SN (1997) Artificial neural networks in prediction of mechanical behavior of concrete at high temperature. Nucl Eng Des 178(1):1–11

Ince R (2004) Prediction of fracture parameters of concrete by artificial neural networks. Eng Fract Mech 71(15):2143–2159

McCulloch WS, Pitts W (1943) A logical calculus of the ideas immanent in neural nets. Bull Math Biophys 5:115–137

Rosenblatt F (1962) Principles of neuro dynamics: perceptrons and the theory of brain mechanisms. Spartan Books, Washington, DC

Rumelhart DE, Hinton GE, William RJ (1986) Learning internal representation by error propagation. In: Rumelhart DE, McClelland JL (eds) Proceeding parallel distributed processing foundation, vol 1. MIT Press, Cambridge

Liu SW, Huang JH, Sung JC, Lee CC (2002) Detection of cracks using neural networks and computational mechanics. Comput Methods Appl Mech Eng 191(25–26):2831–2845

Anderson JA (1983) Cognitive and psychological computation with neural models. IEEE Trans Syst Man Cybern V.SMC-13 5:799–814

Hopfield JJ (1982) Neural networks and physical systems with emergent collective computational abilities. Proc Nat Acad Sci 79:2554–2558

Nazari A, Riahi S (2011) Artificial neural networks to prediction total specific pore volume of geopolymers produced from waste ashes. Neural Comput Appl. doi:10.1007/s00521-011-0760-x

API Specifications 5L (2007) Specifications for line pipe, 44th edn. American Petroleum Institute, Washington DC

Annual Book of ASTM Standards (1997) Metals test methods and analytical, section 3, vol 3.01. ASTM, Easton, USA, pp A751, E8, E23-93a, E45

Iranian Petroleum Standards (IPS) (2004) Material and equipment standard for line pipe, 2nd edn. Iranian Ministry of Petroleum, Tehran, Iran

Pickering FB (1978) Physical metallurgy and the design of steels, materials science series. Applied Science Publishers, London, pp 60–88

Jones BL (1984) ASM international conference on technology and applications of HSLA steels, Philadelphia, PA, 1983. ASM, Metals Park, OH, pp 715–722

Montemarano TW, Sack BP, Gudas JP, Vassilaros MG, Vanderveldt HH (1986) High strength low alloy steels in naval construction. J Ship Prod 2:145–162

Matsuda F, Fukada Y, Okada H, Shiga C, Ikeuchi K, Horii Y, Shiwaka T, Suzuki S (1996) Review of mechanical and metallurgical investigations of martensite-austenite constituent in welded joints in Japan. Welding in the World / Le Soudage dans le Monde, vol 37, issue 4, pp 134–154

Kawabata F, Okatsu M, Amano K, Nakanom Y (1995) Metallurgical and mechanical features of X100 line pipe steel. Pipeline Technol 2:263–271

Nazari A, Riahi S (2011) Prediction split tensile strength and water permeability of high strength concrete containing TiO2 nanoparticles by artificial neural network and genetic programming. Compos B Eng 42:473–488

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khalaj, G., Azimzadegan, T., Khoeini, M. et al. Artificial neural networks application to predict the ultimate tensile strength of X70 pipeline steels. Neural Comput & Applic 23, 2301–2308 (2013). https://doi.org/10.1007/s00521-012-1182-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-012-1182-0