Abstract

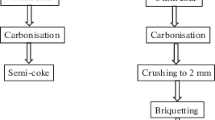

The problem of properly utilizing non-coking coals in alternative iron making processes dates back to long ago. Lean grade coals with higher ash and volatile matter content (e.g. boiler grade coals) have always challenged the metallurgists to develop a suitable process for their utilization. The aim of this work is to achieve an energy efficient method for the reduction of briquetted iron ore fines using ‘SYNGAS’—which is the gaseous product (enriched with reducing agents) generated by pyrolysis of coal along with fine sized carbon particles produced during pyrolysis. A laboratory scale reduction furnace with pyrolysis facility has been designed and fabricated after in depth thermo-gravimetric analysis (TGA), differential thermal analysis (DTA), and gas chromatograph (GC) studies. A particular temperature profile has been maintained inside the furnace to achieve the optimum reduction temperature. The briquettes are reduced in the pyrolysis furnace and the extent of reduction has been calculated from the weight loss. The reduced specimens are characterized using X-ray diffractometer (XRD), scanning electron microscope (SEM), energy dispersive X-ray spectrometer (EDX), field emission scanning electron microscope (FESEM), and chemical analysis method. It is observed that iron ore can be significantly reduced to metallic iron by using the devolatilization product of lean grade coal.

Zusammenfassung

Das Problem der richtigen Anwendung von nichtkokenden Kohlen in alternativen Eisenherstellungsverfahren ist schon lange bekannt. Minderwertige Kohlen mit höherem Aschegehalt und flüchtigen Bestandteilen (z. B. Kesselkohlen) und die Entwicklung eines geeigneten Verfahrens zu ihrer Nutzung haben schon immer die Metallurgen herausgefordert. Das Ziel dieser Arbeit ist die Entwicklung eines energieeffizienten Verfahrens zur Reduktion des brikettierten Feineisenerzes unter Verwendung von SYNGAS. SYNGAS ist das gasförmige Produkt einer Kohleentgasung, welches mit feinen Kohlepartikeln vermischt wird. Dazu wurde ein Reduktionsofen im Labormaßstab mit Entgasungsmöglichkeit nach thermo-gravimetrischen Analysen (TGA), Differentialthermoanalysen (DTA) und Gaschromatographie (GC) Untersuchungen entwickelt. Um die optimale Reduktionstemperatur zu erreichen, wird ein besonderes Temperaturprofil innerhalb des Ofens eingestellt. Die Briketts werden im Pyrolyseofen reduziert, und das Ausmaß der Reduktion wird aus dem Gewichtsverlust berechnet. Die reduzierten Proben werden unter Verwendung von Röntgen-Diffraktometrie (XRD), Rasterelektronenmikroskopie (REM), energiedispersive Röntgenspektrometer (EDX), Feldemissions-Rasterelektronenmikroskop (FE-REM) und chemischen Analyseverfahren charakterisiert. Es wurde beobachtet, dass Eisenerze durch Verwendung des Entgasungsprodukts aus minderwertigen Kohlen zu einem hohen Anteil zu metallischen Eisen reduziert werden können.

Similar content being viewed by others

References

Haque, E. Md.: Indian coal production and ways to increase coal supplies, International Journal of Scientific and Research Publications, 3 (2013), no. 2, pp 1–3

Srinivasan N. S.: Reduction of iron oxides by carbon in a circulating fluidized bed reactor, Powder Technology, 124 (2002), pp 28–39

Kumar, M.; Patel, S. K.: Characteristics of Indian non-coking coal and iron ore reduction by their chars for directly reduced iron production, Mineral Processing and Extractive Metallurgy Review, 29 (2008), no. 3, pp 258–273

Shyam Steel: The facts unearthed, ministry of coal govt. of India, Steel Xpress Coal 12, 2010

Sen, R.; Mukherjee, S.; Dey, R.: Effect of grading of chromite ores on the quality of Briquettes, JISI, 50 (2010), pp 200–206

Cheeley, R.; Leu, M.: Coal gasification for DRI production—An Indian solution, Steel times International, April 2010

Pawlik, C.; Schuster, S.; Eder, N.; Winter, F.; Mali, H.; Fischer, H.; Schenk, J.: Reduction of Iron ore fines with CO-rich gases under pressurized fluid bed conditions, ISIJ International, 47 (2007), no. 2, pp 217–225

Bell, D. A.; Towler, B. F.; Fan, M.: Coal gasification and its applications, Elsevier, 2011

Satos, M.; Hideaki, S.; Kanji, T.: Development of the process for producing pre-reduced agglomerates, JEF Technical Report, 13 (2009), pp 7–13

Tripathy, A. K.; Koria, S. C.; Saxena, M. N.: Preparation of pre-reduced briquettes and studies on the kinetics of the process under reduced pressure’ Symposium on science and technology of sponge iron and its conversion to steel, 1973, pp 128–133

Letimin, V. N.: Briquetting iron-ore materials for blast furnace smelting, Metallurgist, 41(1997), no. 12, pp 407–408

El-Hussiny, N. A.; Shalabi, M. E. H.: Powder technology A self-reduced intermediate product from iron and steel plants waste materials using a briquetting processes, Powder Technology, 205 (2011), pp 217–223

Stull, L. R.; Peapples, P.: Coal analysis (proximate and ultimate) from the delta junction area, Alaska, Division of Geological & Geophysical Surveys, Raw-Data file, 2003, no.1, pp 1–12

Elbeyli, I. Y.; Piskin, S.; Sutcu, H.: Pyrolysis kinetics of Turkish bituminous coals by thermal analysis, Turkish J. Eng. Env. Sci., 28 (2004), pp 233–239

Ohrbach, K. H.; Klusmeler W.; Kuttrup A.: Tg-Dta-Ms investigation of coal, and characterization of the volatile product released as a fuction of temperature, Journal of Thermal Analysis, 29 (1984), pp 147–152

Gangwal, S. K.; Denyszyn, R. B.; Grohse, P. M.; Woganar, D. E.: Analysis of semi-batch coal gasifier product gas using an automated gas chromatograph, Journal of Chromatograph Science 16, (1978) pp 368–371

Cao, Y.; Gao, Z.; Jin, J.; Zhou, H.; Cohron, M.; Zhou, H.; Liu, H.; Pan, W.: Synthesis gas production with an adjustable H2/CO Ratio through the coal gasification process: Effects of coal ranks and methane addition, J. Energy & Fuels, 22 (2008), pp 1720–1730

Acknowledgements

The authors would like to thank Mr. Saikat Samanta, Mr. Supratim Biswas, and Mr. Bitan Kumar Sarkar, Research Scholar, Metallurgical & Material Engineering, Jadavpur University, Kolkata. The authors would also like to express their heartfelt gratitude to Mr. Anirban Sur, Chemist, GSI (Eastern Region), Kolkata (India). One of the authors (Chanchal Biswas) acknowledges the financial support from Technical Quality Improvement Programme (TEQIP) phase-11, Jadavpur University for funding and providing fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Biswas, C., Bhattacharyya, A., Chandra Das, G. et al. A Novel Devolatilization Technique of Pre-reduction of Iron Ore Using Lean Grade Coal. Berg Huettenmaenn Monatsh 161, 95–101 (2016). https://doi.org/10.1007/s00501-015-0401-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00501-015-0401-2