Abstract

The characteristics of initial solidification in continuous casting, especially the peritectic phase transition, have a considerable effect on the surface quality, casting productivity, and operational safety. To supervise the thermal behaviour in the continuous casting mould, an online thermal monitoring system has been installed by voestalpine Stahl GmbH. The higher the temperature fluctuation in the mould, the less uniform the strand surface. This significant operational behaviour corresponds with the peritectic region.

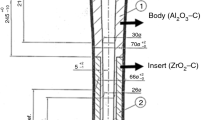

Differential Scanning Calorimeter (DSC) is a proved method which allows a clear prediction of whether an alloy is peritectic or not. In the following study, a combined investigation of selected steel grades by mould thermal monitoring (= casting behaviour) and DSC experiments (= phase transformations) was performed. This first analysis demonstrates a very high correlation of 95 % (for non-high-Al alloyed steel grades) between the measured phase transformations in the lab with the DSC and the real casting behaviour in industry.

Zusammenfassung

Beim Stranggießen haben die Eigenschaften der Anfangserstarrung, insbesondere die peritektische Phasenumwandlung, einen entscheidenden Einfluss auf die Oberflächenqualität, die Produktivität und die Betriebssicherheit. Um das thermische Verhalten in der Stranggießkokille zu überwachen, wurde ein online Überwachungssystem bei der voestalpine Stahl GmbH installiert. Dabei zeigt sich, dass je höher die Temperaturschwankungen in der Kokille sind, desto weniger einheitlich ist die erstarrte Strangoberfläche. Dieses signifikante Betriebsverhalten ist typisch für peritektische Stähle.

Die dynamische Wärmestrom-Differenz-Kalorimetrie (DSC) ist eine erprobte Labor-Methode, mit der man eindeutig bestimmen kann, ob eine Legierung peritektisch ist oder nicht. In der vorliegenden Studie wurde eine kombinierte Untersuchung mittels Kokillen-Monitoring (= Gießverhalten) und DSC-Messungen (= Phasenumwandlungen) von ausgewählten Stahlgüten durchgeführt. Diese erste Analyse zeigt, dass es eine sehr hohe Korrelation von 95 % (für nicht hoch-Al Stahlsorten) zwischen den gemessenen Phasenumwandlungen im Labor mit der DSC und dem realen Gießverhalten in der Industrie gibt.

Similar content being viewed by others

References

Jablonka, A.; Harste, H.; Schwerdtfeger, K.: Thermomechanical properties of iron and iron-carbon alloys: density and thermal contraction, Steel Research, 62 (1991), 1, pp 24–33

Grill, A.; Brimacombe, J. K.: Influence of carbon content on rate of heat extraction in the mould of a continuous-casting machine, Ironmaking and Steelmaking, 3 (1976), 2, pp 76–79

Maehara, Y.; Yasumoto, K.; Tomono, H.; Nagamichi, T.; Ohmori, Y.: Surface cracking mechanism of continuously cast low carbon low alloy steel slabs, Materials Science and Technology, 6 (1990), 9, pp 793–806

Xia, G.; Bernhard, C.; Ilie, S.; Fürst, C.: Why are some peritectic steels susceptible to surface cracking formation for the continuously cast slab, 6th European Conference on Continuous Casting 2008, Riccione, Italy, 3–6 June 2008

Xia, G.: Kokillenmetallurgie des konventionellen Brammenstranggießens von Stahl, Habilitation thesis, Chair of Metallurgy, University of Leoben, 2011

Emi, T.; Fredriksson, H.: High-speed continuous casting of peritectic carbon steels, Materials Science and Engineering, A 413–414 (2005), pp 2–9

Xia, G.; Narzt, H. P.; Fürst, C.; Morwald, K.; Moertl, J.; Reisinger, P.; Lindenberger, L.: Investigation of mould thermal behaviour by means of mould instrumentation, Ironmaking and Steelmaking, 31 (2004), 5, pp 364–370

Wolf, M.: Estimation method of crack susceptibility for new steel grades, 1st European Conference on Continuous Casting, Florence, Italy, September 23–25, 1991, pp 2489–2499

Yamada, H.; Sakurai, T.; Takenouchi, T.: Effect of Alloying Elements on the Peritectic Temperature in Low-Alloy Steels, Tetsu-to-Hagane, 76 (1990), 3, pp 438–445

Kagawa, A.; Okamoto, T.: Influence of alloying elements on temperature and composition for peritectic reaction in plain carbon steels, Materials Science and Technology, 2 (1986), 10, pp 997–1008

Blazek, K. E.; Lanzi III, O.; Gano, P. L.; Kellogg, D. L.: Calculation of the Peritectic Range for Steel Alloys, AISTech 2007, Indianapolis, USA, 7–10 May, 2007

Shepherd, R. E.; Knopp, I.; Brass, H.-G.: The Effect of Alloying Elements on the Peritectic Range in Low Alloyed Cast Steel, 5th International Congress on the Science and Technology of Steelmaking 2012, Dresden 1–3, 2012

Presoly, P.; Pierer, R.; Bernhard, C.: Identification of Defect Prone Peritectic Steel Grades by Analyzing High-Temperature Phase Transformations, Metallurgical and Materials Transactions A, 44A (2013), 12, pp 5377–5388

Presoly, P.; Pierer, R.; Bernhard, C.: Linking up of HT-LSCM and DSC measurements to characterize phase diagrams of steels, IOP Conference Series (MCWASP XIII)—Materials Science and Engineering, 33 (2012), 012064

Höhne, G. W.; Hemminger, H. W.; Flammersheim, H. J.: Differential scanning calorimetry: an introduction for practitioners, Springer, Berlin, 1996

Boettinger, W. J.; Kattner, U. R.; Moon, K.-W.; Perepezko, J. H.: DTA and Heat-flux DSC Measurements of Alloy Melting and Freezing, NIST Recommended Practice Guide, Special Publication 960–15, 2006

Presoly, P.; Xia, G.; Bernhard, C.: Identification of peritectic steel grades by thermal mould monitoring and DSC measurements. 8th European Continuous Casting Conference, Graz, Österreich, 23–26 June 2014

Miettinen, J.: Reassessed thermodynamic solution phase data for ternary Fe-Si-C system, Calphad, 22 (1998), pp 231–256

ThermoCalc, version 5 (2010), Database TCFE 6

Acknowledgements

Financial support by the Austrian Federal Government (in particular by the Bundesministerium für Verkehr, Innovation und Technologie and Bundesministerium für Wirtschaft, Familie und Jugend) represented by Österreichische Forschungsförderungsgesellschaft mbH and the Styrian and the Tyrolean Provincial Governments, represented by Steirische Wirtschaftsförderungsgesellschaft mbH and Standortagentur Tirol respectively, within the framework of the COMET Funding Programme; and the industry partners Siemens VAI Metals Technologies GmbH and voestalpine Stahl GmbH. We gratefully acknowledge the support from all partners.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Presoly, P., Xia, G., Reisinger, P. et al. Continuous Casting of Hypo-peritectic Steels: Mould Thermal Monitoring and DSC-analysis. Berg Huettenmaenn Monatsh 159, 430–437 (2014). https://doi.org/10.1007/s00501-014-0306-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00501-014-0306-5

Keywords

- Peritectic steel

- Continuous casting

- Temperature fluctuation

- Temperature variation coefficient

- Phase transformations

- Cp-formula

- DSC measurements

- Mould monitor