Summary

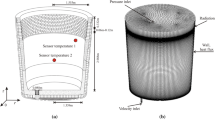

An important stage has been reached in the development of a comprehensive model of a steelmaking reactor with the realization of a numerical simulation coupling a thermodynamic module (CEQCSI for Chemical EQuilibrium Calculation for the Steel Industry), developed by Arcelor Research, and a commercial fluid dynamic software (Fluent). Fluent performs computations for liquid steel and determines the temperature and distribution of dissolved chemical elements and nonmetallic inclusions. These are regularly transferred to CEQCSI, which, assuming local equilibrium conditions, calculates the new state of equilibrium of the dissolved elements and the evolution of the inclusions population. Based on this weak two-way coupling, the first numerical results concerning the deoxidation process of liquid steel by aluminum during the secondary refinement are obtained. Al, O and Al2O3 concentrations are predicted within the studied reactor (RH) and heterogeneities in the volume can be highlighted. This tool gives the possibility to study the effect of different factors on the process and on the final quality of the products (metal cleanliness). The model can moreover give precise information for a better understanding of the nozzle clogging due to the alumina inclusions formation.

Zusammenfassung

Ein wichtiger Schritt in der Entwicklung eines umfangreichen Stahlreaktor-Modells wurde durch numerische Kopplung eines thermodynamischen Moduls (CEQCSI, Chemische Gleichgewichtsberechnung für die Stahlindustrie), entwickelt von Arcelor Research, und einer kommerziellen Software für Strömungsdynamik (Fluent) erreicht. Fluent berechnet die Temperatur und die Verteilung von gelösten chemischen Elementen und nichtmetallischen Einschlüssen in der Stahlschmelze. Diese Daten werden regelmäßig zur CEQCSI gesendet, welche, unter der Annahme lokaler Gleichgewichtsbedingungen, den neuen Stand von gelösten Elementen im chemischen Gleichgewicht und die Entwicklung der Einschlusspopulation berechnet. Basierend auf dieser simplen Zweifachkopplung, wurden die ersten numerischen Ergebnisse eines Desoxidationsprozesses mit Aluminium errechnet. Al-, O- und Al203-Konzentrationen zeigten im untersuchten Reaktor (RH) Heterogenitäten. Dieses Modell macht die Untersuchung der Wirkung verschiedener Faktoren auf den Prozess und auf die Qualität des Endproduktes (Reinheitsgrad des Stahls) möglich. Das Modell gibt zusätzlich wertvolle Informationen für ein besseres Verständnis vom Zuwachsen des Tauchrohres durch die Bildung von Aluminiumoxid-Einschlüssen.

Similar content being viewed by others

References

Hallberg, M., L. Jonnsson, and J. Alexis: Modelling of hydrogen and sulphur refining during vacuum degassing in a ladle furnace'. SCANMET 1, Lulea, (1999)

Domgin, J.F., and P. Gardin: Modelling inclusions behaviour in RH steelmaking reactor to improve steel cleanliness. Trends in numerical and physical modelling for industrial multiphase flows, Cargèse, (2001)

Guo, D. and G.A. Irons: Modeling of gas-liquid reactions in ladle metallurgy: Part II. Numerical Simulation, Metal and Material Trans. B, 31B, (2000), 1457–1464

Domgin, J-F., D. Huilier, J-J. Karl, P. Gardin, and H. Burnage: Experimental and numerical study of rigid particles, droplets and bubbles motion in quiescent and turbulent flows – Influence of the history force. ICMF98, Lyon, (1998)

Fluent User's Guide (2002), Fluent Incorporated, Volumes 2 and 3

Boisson, N., and M.R. Malin: Numerical prediction of two-phase flow in bubble columns. International Journal for Numerical Methods in Fluids, 23 (1996), 1289–1310

Tomiyama, A.: Struggle with computational bubble dynamica. Third International Conference on Multiphase Flow, ICMF 98 Lyon, France, June 8–12 (1998)

Domgin, J.F., P. Gardin, H. Saint-Raymond, F. Stouvenot, and D. Huin: Carbon concentration in ULC steels numerically tracked in vacuum processes. Steel Res. International, 76 (2005), 5–12

Kuwabara, T., K. Umezawa, K. Mori, and H. Watanabe: Trans. Iron Steel Inst. Jpn., 28 (1988), 305

Park, Y-G., K-W. Yi, and S-B. Ahn: The effect of operating parameters and dimensions of the RH system on melt circulation using numerical calculations. ISIJ International, 41 (2001), 403–409

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Simonnet, M., Domgin, J., Lehmann, J. et al. Numerical Tool Coupling Fluid Dynamics and Thermochemistry to Predict and to Optimize Deoxidation Processes. Berg Huettenmaenn Monatsh 152, 350–354 (2007). https://doi.org/10.1007/s00501-007-0327-4

Issue Date:

DOI: https://doi.org/10.1007/s00501-007-0327-4