Abstract

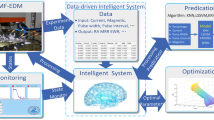

Processing of Inconel 718 is still big challenge for manufactures to process with better machining performance and less environmental effect. Therefore, the present study was aimed to develop a sustainable magnetic field-assisted electrical discharge machining (MEDM) for machining of Inconel 718 to reduce power consumption, aerosol emissions and surface defects. Experiments were conducted at different levels of current, pulse on time, pulse off time and voltage with and without magnetic field assistance and the experimental results for power consumption, aerosol emissions, metal removal rate (MRR) and surface roughness were collected and analyzed. The power consumption, surface roughness, recast layers, microcracks, microvoids and microglobules were found to be reduced with improved MRR in the MEDM. A hybrid teaching learning-based optimization algorithm was proposed and optimized the process parameters in MEDM. With the proposed methodology, the MRR, surface roughness, power consumption and aerosol emissions reached 82%, 80%, 87% and 68% of the specified targets, respectively. The optimum process parameters were 4 A of current, 106 µs of pulse on time, 79 µs of pulse off time, 38 V of voltage.

Similar content being viewed by others

Data availability

No data was associated with this article.

References

Agarwal D, Singh P, Sayed MAE (2023) The Karush–Kuhn–Tucker (KKT) optimality conditions for fuzzy-valued fractional optimization problems. Math Comput Sim 205:861–877

Aishwarya P, Kunal C, Eswara KM (2019) Investigations on power consumption in WEDM of EN31 steel for sustainable production. Mater Manuf Proc 237(16):1855–1865

Chaitanyareddy M, Rao KV, Suresh G (2021) An experimental investigation and optimization of energy consumption and surface defects in wire cut electric discharge machining. J Alloy Comput 851:158582

Daniel NA, Vates UK, Sharma BP, Kanu NJ, Subramonian S (2021) Optimization of Inconel die-in EDD steel deep drawing with influence of punch coating using RSM. Adv Ind Prod Eng. https://doi.org/10.1007/978-981-33-4320-7_64

Das S, Paul S, Doloi B (2021) A gap-active electrical discharge machining (GA-EDM) to rectify the textural defects of the processed surface. J Manuf Proc 64:594–605

Dong S, Wang Z, Wang Y (2017) Research on micro-EDM with an auxiliary electrode to suppress stray-current corrosion on C17200 beryllium copper alloy in deionized water. Int J Adv Manuf Tech 93(1–4):857–867

Elsisy MA, Elsaadany AS, Sayed MAE (2020) Using interval operations in the Hungarian method to solve the fuzzy assignment problem and its application in the rehabilitation problem of valuable buildings in Egypt. Complexity 2020:9207650

Elsisy MA, Sayed MAE, Elnaga YA (2021) A novel algorithm for generating Pareto frontier of bi-level multi-objective rough nonlinear programming problem. Ain Sha Eng J 12(2):2125–2133

Gonfa BK, Sinha D, Vates UK, Badruddin IA, Hussien M, Kamangar S, Singh GK, Ahmed GMS, Kanu NJ, Hossain N (2022) Investigation of mechanical and tribological behaviors of aluminum based hybrid metal matrix composite and multi-objective optimization. Materials 15(16):5607

Goswami K, Samuel GL (2020) Non-linear model of energy consumption for in-process control in electrical discharge machining. Int J Adv Manuf Technol 110:1543–1561

Halwe AD, Deshmukh SJ, Kanu NJ, Gupta E, Tale RB (2021) Optimization of the novel hydrodynamic cavitation based waste cooking oil biodiesel production process parameters using integrated L9 Taguchi and RSM approach. Mater Today: Proc 47:5934–5941

Hardik B, Pandey PM (2021) Experimental investigations to evaluate the surface integrity in the magnetic feld and air/gas assisted EDM. J Braz Soc Mech Sci Eng 43:213

Jadam T, Sahu SK, Datta S, Manoj M (2019) EDM performance of Inconel 718 superalloy: application of multi walled carbon nanotube (MWCNT) added dielectric media. J Braz Soc Mech Sci Eng 41:305

Kanu NJ, Gupta E, Vates UK, Kumar Singh GK (2020) Electrospinning process parameters optimization for biofunctional curcumin/gelatin nanofibers. Mater Res Express 7:035022

Krishnakant D, Kuldeep C, Akshay D, Omkar B (2019) An environment-friendly and sustainable machining method: near-dry EDM. Mater Manuf Proc 34(12):1307–1315

Li Z, Tang J, Li Y, Bai J (2022) Investigation on surface integrity in novel micro-EDM with two-dimensional ultrasonic circular vibration (UCV) electrode. J Manuf Proc 76:828–840

Ming W, Shen F, Zhang Z, Huang H, Du J, Wu J (2020) A comparative investigation on magnetic field–assisted EDM of magnetic and non-magnetic materials. Int J Adv Manuf Technol 109:1103–1116

Mishra M, Ramana GV, Damodar M (2020) Teaching–learning-based optimisation algorithm and its application in capturing critical slip surface in slope stability analysis. Soft Comput 24:2969–2982

Muthuramalingam T (2019) Effect of diluted dielectric medium on spark energy in green EDM process using TGRA approach. J Clean Prod 238:117894

Ong P, Chong CH, bin Rahim MZ, Lee WK, Sia CK, bin Ahmad MAH (2020) Intelligent approach for process modelling and optimization on electrical discharge machining of polycrystalline diamond. J Intell Manuf 31:227–247

Paolucci M, Anghinolfi D, Tonelli F (2017) Facing energy-aware scheduling: a multi-objective extension of a scheduling support system for improving energy efficiency in a moulding industry. Soft Comput 21:3687–3698

Paramashivam SS, Mathew J, Mahadevan S (2012) Mathematical modelling of aerosol emissions from die sinking electrical discharge machining process. Appl Math Model 36:1493–1503

Rao KV (2019) Power consumption optimization strategy in micro ball-end milling of D2 steel via TLBO coupled with 3D FEM simulation. Measurement 132:68–78

Rao KV (2021) The use of teaching-learning based optimization technique for optimizing weld bead geometry as well as power consumption in additive manufacturing. J Clean Prod 279:123891

Rao KV, Murthy PBGSN, Vidhu KP (2017) Assignment of weightage to machining characteristics to improve overall performance of machining using GTMA and utility concept. CIRP J Manuf Sci Technol 18:152–158

Rao KV, Satish P, Raju LS, Suresh G (2022) Modelling and optimization of weld bead geometry in robotic gas metal arc based additive manufacturing using machine learning, finite element modelling and graph theory and matrix approach. Soft Comput 26:3385–3399

Roy T, Kumar RD (2019) Integrated fuzzy AHP and fuzzy TOPSIS methods for multi-objective optimization of electro discharge machining process. Soft Comput 23:5053–5063

Sachin RP, Kiran CP (2019) A review of magnetic assisted machining processes. J Braz Soc Mech Sci Eng 41:450

Sayed MAE, Sinna MAA (2021) A novel approach for fully intuitionistic fuzzy multi-objective fractional transportation problem. Alex Eng J 60(1):1447–1463

Sayed MAE, Baky IA, Singh P (2020) A modified TOPSIS approach for solving stochastic fuzzy multi-level multi-objective fractional decision-making problem. Opsearch 57:1374–1403

Sayed MAE, Farahat FA, Elsisy MA (2022) A novel interactive approach for solving uncertain bi-level multi-objective supply chain model. Com Indl Eng 169:108225

Sharma P, Chakradhar D, Narendranath S (2021) Measurement of WEDM performance characteristics of aero-engine alloy using RSM-based TLBO algorithm. Measurement 179:109483

Sharma D, Bhowmick A, Goyal A (2022) Enhancing EDM performance characteristics of Inconel 625 superalloy using response surface methodology and ANFIS integrated approach. CIRP J Manuf Sci Technol 37:155–173

Singh M, Singh S (2020) Multi-objective optimization of electrical discharge machining of Nimonic 75 using teaching learning based optimization (TLBO) algorithm. Mat Today: Proc 24(2):576–584

Singh AK, Bal KS, Pal AR, Dey D, Choudhury AR (2021) A novel method to reduce dross in laser beam cutting of Ti-6Al-4 V alloy sheet. J Manuf Proc 64:95–112

Talebizadehsardari P, Eyvazian A, Khan A, Sebaey TA (2021) Measurement and evaluation of magnetic field assistance on fatigue life and surface characterization of Inconel 718 alloy processed by dry electrical discharge turning. Measurement 173:108578

Vates UK, Sharma BP, Kanu NJ, Daniel NA, Subramanian S, Sharma P (2020) Optimization of process parameters of galvanizing steel in resistance seam welding using RSM. Proc Int Conf Mech Energy Technol. https://doi.org/10.1007/978-981-15-2647-3_65

Vates UK, Kanu NJ, Gupta E, Singh GK, Sharma BP, Pandey V (2021a) Optimization of electro discharge critical process parameters in tungsten carbide drilling using L9 Taguchi approach. Mater Today: Proc 47(11):3227–3234

Vates UK, Kanu NJ, Singh GK, Daniel NA, Sharma BP (2021b) Optimization of FDM 3D printing process parameters on ABS based Bone Hammer using RSM technique. IOP Conf Ser: Mater Sci Eng 1206(1):012001

Vates UK, Sharma BP, Kanu NJ, Gupta E, Singh GK (2022) Modeling and optimization of IOT factors to enhance agile manufacturing strategy-based production system using SCM and RSM. Sma Sci 10(2):158–173

Venkatarao R, Savsani VJ, Vakharia DP (2011) Teaching-learning-based optimization: a novel method for constrained mechanical design optimization problems. Comput Aid Des 43(3):303–315

Xu B, Chen SG, Liang X, Lei J, Shi H, Fu H, Yang J, Peng T, Zhao H, Zhu L (2020) Recast layer removal of 304 stainless steel by combining micro-EDM with negative polarity micro-EDM. Int J Adv Manuf Technol 107:4713–4723

Zhang Z, Yu H, Zhang Y, Yang K, Li W, Chen Z, Zhang G (2018) Analysis and optimization of process energy consumption and environmental impact in electrical discharge machining of titanium superalloys. J Clean Prod 198:833–846

Zhang Z, Zhang Y, Lin L, Wu J, Yu H, Pan X, Li G, Wu J, Xue T (2021) Study on productivity and aerosol emissions of magnetic field-assisted EDM process of SiCp/Al composite with high volume fractions. J Clean Prod 292:126018

Zhao WZ (2021) Processes for environmentally friendly and/or cost-effective manufacturing. Mater Manuf Proc 36(9):987–1009

Funding

This work was not supported by any external funding agencies.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no potential conflicts of interest among the authors.

Research involving human participants and/or animals

The present research was done on any human beings and animals.

Human or animal rights and informed consent

As the present research was done on any human beings and animals, it does not require any informed consent/permission from anywhere.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rao, K.V., Kumar, Y.P. & Shaik, F. Measurement and optimization of power consumption and aerosol emissions in magnetic field-assisted electrical discharge machining of Inconel 718. Soft Comput 27, 11451–11468 (2023). https://doi.org/10.1007/s00500-023-08292-9

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-023-08292-9