Abstract

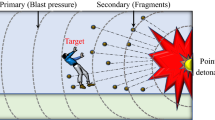

This paper presents the effect of sandwich panel with two types of dimple core surface and solid plate core on its ballistic properties and strength . The current core such as foam, honeycomb, and lattice cores have cavity and porosity on its structure which made them vulnerable to catastrophic failure due to high impact. This paper aims to enhance the ballistic resistance of panel using enhanced core configuration. A simulation was conducted using computational method of explicit dynamic under high-speed projectile impact at 980 m/s of 7.62 mm armour-piercing metal. A half-symmetric of three-dimensional sandwich panel with 27 mm thickness including adhesive material was modelled with a mesh refinement of 1 mm and added with the modified Johnson–Cook parameters to describe the ballistic behaviour of each materials. The results show that the use of dimple surface as the core for sandwich panel has increased the ballistic performance by approximately 30% from the solid core. No macrocrack or petal showed at the back layer except of bulges effect. Magnesium alloy as core material showed high potential to be used as main core for sandwich panel on protection application by decrement in projectile penetration about 4.5% compared to aluminium alloy. This study proposed that the structural integrity of the metal sandwich panel with proposed core configuration has improved with no significant reduction in ballistic performance compared to the sandwich panel with solid core.

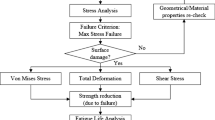

Graphic abstract

Similar content being viewed by others

Data availability statement

The processed data/material required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Abdul Rahman N, Abdullah S, Abdullah MF, Omar MZ, Sajuri Z, Zamri WFH (2018) Ballistic limit of laminated panels with different joining materials subjected to steel-hardened core projectile. Int J Integr Eng 10:8–14

Abdullah MF, Abdullah S, Omar MZ, Sajuri Z, Sohaimi RM (2015) Failure observation of the AZ31B magnesium alloy and the effect of lead addition content under ballistic impact. Adv Mech Eng 7:1–13

Abdullah MF, Abdullah S, Rahman NA, Risby MS, Omar MZ, Sajuri Z (2016) Improvement of high velocity impact performance of carbon nanotube and lead reinforced magnesium alloy. Int J Autom Mech Eng 13:3423–3433

Abdullah S, Abdullah MF, Zulkefli AS, Mazlan NH (2019) Numerical impact strain response of multi-layered steel–aluminium plate using signal processing. J Braz Soc Mech Sci Eng 41:1–9

Birman V, Kardomateas GA (2018) Review of current trends in research and applications of sandwich structures. Compos B Eng 142:221–240

Børvik T, Langseth M, Hopperstad OS, Malo K (2001) A perforation of 12mm thick steel plates by 20 mm diameter projectiles with flat, hemispherical and conical noses-Part I: experimental study. Int J Impact Eng 27:19–35

Duplan Y, Saletti D, Forquin P (2019) Identification of the quasi-static and dynamic behaviour of projectile-core steel by using shear-compression specimens. Metals 9:216

Feng F, Huang S, Meng Z, Hu J, Lei Y, Zhou M, Yang Z (2014) A constitutive and fracture model for AZ31B magnesium alloy in the tensile state. Mater Sci Eng A 594:334–343

Flores-Johnson EA, Saleh M, Edwards L (2011) Ballistic performance of multi-layered metallic plates impacted by a 7.62-mm APM2 projectile. Int J Impact Eng 38:1022–1032

Gunes R, Arslan K, Apalak MK, Reddy J (2019) Ballistic performance of honeycomb sandwich structures reinforced by functionally graded face plates. J Sandwich Struct Mater 21:211–229

Hazell PJ, Appleby-Thomas GJ, Toone S (2014) Ballistic compaction of a confined ceramic powder by a non-deforming projectile: experiments and simulations. Mater Des 56:943–952

He W, Liu J, Wang S, Xie D (2018) Low-velocity impact behavior of X-Frame core sandwich structures—experimental and numerical investigation. Thin-Walled Struct 131:718–735

Howard D, Brezulianu A (2011) Capturing expert knowledge of mesh refinement in numerical methods of impact analysis by means of genetic programming. Soft Comput 15:103–110. https://doi.org/10.1007/s00500-010-0684-x

Jia Y, Bai Y (2016) Experimental study on the mechanical properties of AZ31B-H24 magnesium alloy sheets under various loading conditions. Int J Fract 197:25–48

Kaboglu C, Pimenta S, Morris A, Dea JP (2017) The effect of different types of core material on the flexural behavior of sandwich composites for wind turbine blades. J Thermal Eng 3:1102–1109

Kamgar R, Bagherinejad MH, Heidarzadeh H (2020) A new formulation for prediction of the shear capacity of FRP in strengthened reinforced concrete beams. Soft Comput 24:6871–6887. https://doi.org/10.1007/s00500-019-04325-4

Kılıç N, Ekici B (2013) Ballistic resistance of high hardness armor steels against 7.62 mm armor piercing ammunition. Mater Des 44:35–48

Latif NA, Sajuri Z, Syarif J (2014) Effect of aluminium content on the tensile properties of Mg–Al–Zn alloys. Jurnal Kejuruteraan 26:35–39

Lee WG, Kim JS, Sun SJ, Lim JY (2018) The next generation material for lightweight railway car body structures: magnesium alloys. Proc IMechE Part F J Rail Rapid Transit 232:25–42

Liang Y, Qin H, Huang J, Huan S, Hui D (2019) Mechanical properties of boron nitride sheet with randomly distributed vacancy defects. Nanotechnol Rev 8:210–217

Liu J, Chen T, Zhang Y, Wen G, Qing Q, Wang H, Sedaghati R, Xie YM (2019) On sound insulation of pyramidal lattice sandwich structure. Compos Struct 208:385–394

Liu W, Chen Z, Chen Z, Cheng X, Wang Y, Chen X, Liu J (2015) Influence of different back laminate layers on ballistic performance of ceramic composite armor. Mater Des 87:421–427

Liu J, Liu J, Mei J, Huang W (2018) Investigation on manufacturing and mechanical behavior of all-composite sandwich structure with Y-shaped cores. Compos Sci Technol 159:87–102

Maji K, Kumar G (2020) Inverse analysis and multi-objective optimization of single-point incremental forming of AA5083 aluminum alloy sheet. Soft Comput 24:4505–4521. https://doi.org/10.1007/s00500-019-04211-z

Pham AD, Ngo NT, Nguyen QT, Truong NS (2020) Hybrid machine learning for predicting strength of sustainable concrete. Soft Comput 24:14965–14980. https://doi.org/10.1007/s00500-020-04848-1

Rahman NA, Abdullah S, Abdullah MF, Zamri WFH, Omar MZ, Sajuri Z (2018) Experimental and numerical investigation on the layering configuration effect to the laminated aluminium/steel panel subjected to high speed impact test. Metals 8(732):1–16

Ren L, Fan L, Zhou M, Guo Y, Zhang Y, Boehlert CJ, Quan G (2018) Magnesium application in railway rolling stocks: a new challenge and opportunity for Lightweighting. Int J Lightw Mater Manuf 1:81–88

Salviato M, Zappalorto M, Quaresimin M (2011) The effect of surface stresses on the critical debonding stress around nanoparticles. Int J Fract 172:97–103

Szymczyk M, Sumelka W, Łodygowski T (2018) Numerical investigation on ballistic resistance of aluminium multi-layered panels impacted by improvised projectiles. Arch Appl Mech 88:51–63

Tang E, Zhang X, Han Y (2019) Experimental research on damage characteristics of CFRP/aluminum foam sandwich structure subjected to high velocity impact. J Market Res 8:4620–4630

Tarkesh Esfahani R, Golabi S, Zojaji Z (2016) Optimization of finite element model of laser forming in circular path using genetic algorithms and ANFIS. Soft Comput 20:2031–2045. https://doi.org/10.1007/s00500-015-1622-8

Tiancai X, Yang Y, Xiaodong P, Jiangfeng S, Fusheng P (2019) Overview of advancement and development trend on magnesium alloy. J Magn Alloys 7:536–544

Tiwari G, Thomas T, Khandelwal RP (2018) Influence of reinforcement in the honeycomb structures under axial compressive load. Thin-Walled Struct 126:238–245

Vijaya RB, Elanchezhian C, Manickavasagam VM, Surya NR, Sudharshan R, Pugazhendhi G (2019) A Review on sandwich composites and their advancements. Mater Today Proc 16:1146–1151

Violano G, Demelio G, Afferrante L (2019) A note on the effect of surface topography on adhesion of hard elastic rough bodies with low surface energy. J Mech Behav Mater 28:8–12

Wang C, Suo T, Li Y, Xue P, Tang Z (2018) A new experimental and numerical framework for determining of revised J-C failure parameters. Metals 8(396):1–12

Wang Z (2019) Recent advances in novel metallic honeycomb structure. Compos B 166:731–741

Wei Z, Yunfei D, Sheng CZ, Gang W (2012) Experimental investigation on the ballistic performance of monolithic and layered metal plates subjected to impact by blunt rigid projectiles. Int J Impact Eng 49:115–129

Weiss A, Stan G B -M (2016) Behaviour of multi-layered metal plates under ballistic impact. In: Proc of 29th Int Symp on Ballistics, Edinburgh, Scotland UK 1925–1935.

Yafu F, Qu-dong W, Jun-sheng N, Jie C, Wei J (2010) Experimental measure of parameters: the Johnson–Cook material model of extruded Mg-Gd-Y series alloy. J Appl Mech Trans ASME 77:051902–1-051902–5

Acknowledgements

The authors would like to acknowledge the facilities support provided by Computational Laboratory in Universiti Kebangsaan Malaysia and Universiti Pertahanan Nasional Malaysia.

Funding

This research was funded by Universiti Kebangsaan Malaysia (DIP-2019–015) and Ministry of Higher Education Malaysia (FRGS/1/2019/TK03/UKM/01/3).

Author information

Authors and Affiliations

Contributions

The following contributions to this work were made by the following authors ‐ M.K.F., S.A., and M.F.A. contributed to conceptualization and investigation; S.A, M.F.A., A.H.A., and S.S.K.S. were involved in resources; S.A., M.F.A., A.H.A, S.S.K.S, and D.H. contributed to supervision; M.F.A. was involved in software; M.K.F., S.A. contributed to writing‐original draft preparation; M.K.F., S.A., A.H.A., S.S.K.S., and D.H were involved in writing‐review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Faidzi, M.K., Abdullah, S., Abdullah, M.F. et al. Computational analysis on the different core configurations for metal sandwich panel under high velocity impact. Soft Comput 25, 10561–10574 (2021). https://doi.org/10.1007/s00500-021-06015-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-021-06015-6