Abstract

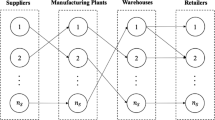

The concentration of this paper is to measure and break supply chain planning decisions under market and/or technical uncertainty. A three-level supply chain with manufacturers–distributors–customer’s loops is considered that customer demands, percent of back products from customers and shipping time of products from distributors to customers are considered as fuzzy variables. The main approach considers suppliers and distributor selection and determines the affected customers in the system problems simultaneously under uncertain conditions. The objects of the proposed model are maximizing the quality of products and income and minimizing the total cost and the shipping time from distributors to customers. Also, in the proposed model we consider some constraints such as lack of orders, production capacity and customer demands. Also, a two-organize, stochastic programming methodology is proposed for joining request vulnerability in multisite midterm store network arranging issues. The assessment of the normal second-stage expenses is accomplished by expository reconciliation yielding an equivalent convex mixed-integer nonlinear problem. At long last, a real options-based valuation (ROV) system for supporting under vulnerability is produced. Multistage stochastic writing computer programs are utilized to fuse vulnerability and a quantitative correlation of the ROV approach, and the customary net-present-value approach is given.

Similar content being viewed by others

References

Abdulaal A, Moghaddass R, Asfour S (2017) Two-stage discrete-continuous multi-objective load optimization: an industrial consumer utility approach to demand response. Appl Energy 206:206–221

Ahmed S, Sahinidis NV (1998) Robust process planning under uncertainty. Ind Eng Chem Res 37(5):1883–1892

Alexander AE, Walker HL (2016) Decision making in sustainable supply chain management: cross-sector case studies of implementation. http://orca.cf.ac.uk/id/eprint/87181

Alshehri K, Bose S, Başar T (2017) Cash-settled options for wholesale electricity markets. arXiv preprint arXiv:1704.00369

Amid A, Ghodsypour S, O’Brien C (2006) Fuzzy multiobjective linear model for supplier selection in a supply chain. Int J Prod Econ 104(2):394–407

Amiri A (2006) Designing a distribution network in a supply chain system: formulation and efficient solution procedure. Eur J Oper Res 171(2):567–576

Amram M, Kulatilaka N (1999) Disciplined decisions: aligning strategy with the financial markets. Harvard Bus Rev 77(1):95–104

Anupindi R et al (1999) Quantitative models for supply chain management. Kluwer Academic Publishers, Norwell

Aswath D (2001) Corporate finance: theory and practice, International edn. Willey, New York

Bakir MA, Byrne MD (1998) Stochastic linear optimisation of an MPMP production planning model. Int J Prod Econ 55(1):87–96

Baykasoǧlu A, Göçken T (2008) A review and classification of fuzzy mathematical programs. J Intell Fuzzy Syst 19(3):205–229

Beier S et al (2017) Supply chain management using mobile devices. Google Patents

Bellman RE, Zadeh LA (1970) Decision-making in a fuzzy environment. Manag Sci 17(4):B-141–B-164

Beske P, Land A, Seuring S (2014) Sustainable supply chain management practices and dynamic capabilities in the food industry: a critical analysis of the literature. Int J Prod Econ 152:131–143

Bessler SA, Veinott AF (1966) Optimal policy for a dynamic multi-echelon inventory model. Naval Res Logist (NRL) 13(4):355–389

Bidhandi HM, Yusuff RM (2011) Integrated supply chain planning under uncertainty using an improved stochastic approach. Appl Math Model 35(6):2618–2630

Black F, Scholes M (1973) The pricing of options and corporate liabilities. J Polit Econ 81(3):637–654

Bollapragada S, Akella R, Srinivasan R (1998) Centralized ordering and allocation policies in a two-echelon system with non-identical warehouses. Eur J Oper Res 106(1):74–81

Brandenburg M et al (2014) Quantitative models for sustainable supply chain management: developments and directions. Eur J Oper Res 233(2):299–312

Burgess TF, Grimshaw P, Huaccho Huatuco L, Shaw NE (2017) Mapping the operations and supply chain management field: a journal governance perspective. Int J Oper Prod Manag 37(7):898–926

Busse C et al (2017) Under the umbrella of sustainable supply chain management: emergent solutions to real-world problems. Int J Phys Distrib Logist Manag 47(5):342–343

Cardin M-A et al (2017) An approach for analyzing and managing flexibility in engineering systems design based on decision rules and multistage stochastic programming. IISE Trans 49(1):1–12

Chan F, Chan H (2004) A new model for manufacturing supply chain networks: a multiagent approach. Proc Inst Mech Eng B J Eng Manuf 218(4):443–454

Chen C-L, Lee W-C (2004) Optimization of multi-echelon supply chain networks with uncertain sales prices. J Chem Eng Jpn 37(7):822–834

Chen C-L, Wang B-W, Lee W-C (2003) Multiobjective optimization for a multienterprise supply chain network. Ind Eng Chem Res 42(9):1879–1889

Chiang W-YK, Monahan GE (2005) Managing inventories in a two-echelon dual-channel supply chain. Eur J Oper Res 162(2):325–341

Chung Y et al (2018) Improved neighborhood search for collaborative filtering. Int J Fuzzy Log Intell Syst 18(1):29–40

Clark AJ, Scarf H (1960) Optimal policies for a multi-echelon inventory problem. Manag Sci 6(4):475–490

Clay R, Grossmann I (1997) A disaggregation algorithm for the optimization of stochastic planning models. Comput Chem Eng 21(7):751–774

Cole RA, Floros IV, Ivanov VI (2016) Reducing uncertainty through a two-stage IPO. Working paper, available at SSRN 2808852

Costantino N, Pellegrino R, Tauro D (2016) Commodity price volatility mitigation in supply chain risk management: real options to assess the value of flexibility-driven strategies. In: 2016 IEEE international conference on industrial engineering and engineering management (IEEM). IEEE

Cox JC, Ross SA, Rubinstein M (1979) Option pricing: a simplified approach. J Financ Econ 7(3):229–263

Dabestani R et al (2017) Evaluation and prioritization of service quality dimensions based on gap analysis with analytic network process. Int J Qual Reliab Manag 34(4):530–548

Dantzig GB (1955) Upper bounds, secondary constraints, and block triangularity in linear programming. Econom J Econom Soc 174–183

Dantzig GB, Orden A, Wolfe P (1955) The generalized simplex method for minimizing a linear form under linear inequality restraints. Pac J Math 5(2):183–195

Devalkar SK, Anupindi R, Sinha A (2017) Dynamic risk management of commodity operations: model and analysis. Manuf Serv Oper Manag 20(2):317–332

Diks EB, De Kok A (1998) Optimal control of a divergent multi-echelon inventory system. Eur J Oper Res 111(1):75–97

Dimitriadis A, Shah N, Pantelides C (1997) RTN-based rolling horizon algorithms for medium term scheduling of multipurpose plants. Comput Chem Eng 21:S1061–S1066

Dixit AK, Pindyck RS (1994) Investment under uncertainty. Princeton University Press, Princeton

Dong L, Lee HL (2003) Optimal policies and approximations for a serial multiechelon inventory system with time-correlated demand. Oper Res 51(6):969–980

Dubois D, Fargier H, Fortemps P (2003) Fuzzy scheduling: Modelling flexible constraints vs. coping with incomplete knowledge. Eur J Oper Res 147(2):231–252

Eppen G, Schrage L (1981) Centralized ordering policies in a multi-warehouse system with lead times and random demand. Multi-level Prod Inventory Control Syst Theory Pract 16:51–67

Escudero LF et al (1993) Production planning via scenario modelling. Ann Oper Res 43(6):309–335

Eskigun E et al (2007) Outbound supply chain network design with mode selection and lead time considerations. Naval Res Logist (NRL) 54(3):282–300

Farahani RZ, Elahipanah M (2008) A genetic algorithm to optimize the total cost and service level for just-in-time distribution in a supply chain. Int J Prod Econ 111(2):229–243

Fredendall LD, Letmathe P, Uebe-Emden N (2016) Supply chain management practices and intellectual property protection in China: perceptions of Mittelstand managers. Int J Oper Prod Manag 36(2):135–163

García-Flores R, Wang XZ (2002) A multi-agent system for chemical supply chain simulation and management support. OR Spectr 24(3):343–370

Georgiadis MC, Pistikopoulos EN (1999) An integrated framework for robust and flexible process systems. Ind Eng Chem Res 38(1):133–143

Gholamian N, Mahdavi I, Tavakkoli-Moghaddam R (2016) Multi-objective multi-product multi-site aggregate production planning in a supply chain under uncertainty: fuzzy multi-objective optimisation. Int J Comput Integr Manuf 29(2):149–165

Giannoccaro I, Pontrandolfo P, Scozzi B (2003) A fuzzy echelon approach for inventory management in supply chains. Eur J Oper Res 149(1):185–196

Goldstein MA, Kwan A, Philip R (2018) High-frequency trading strategies. Available at SSRN 2973019

Gonzalez EDS, Jabbour CJ (2017) Advances in supply chain and logistics management for a more sustainable society: an introduction. J Oper Supply Chain Manag 10(1):1–2

Gumus AT, Guneri AF (2009) A multi-echelon inventory management framework for stochastic and fuzzy supply chains. Expert Syst Appl 36(3):5565–5575

Gupta A, Maranas CD (2000) A two-stage modeling and solution framework for multisite midterm planning under demand uncertainty. Ind Eng Chem Res 39(10):3799–3813

Gupta A, Maranas CD (2001) Multiperiod planning of multisite supply chains under demand uncertainty. Comput Aided Chem Eng 9:871–876

Gupta A, Maranas CD, McDonald CM (2000) Mid-term supply chain planning under demand uncertainty: customer demand satisfaction and inventory management. Comput Chem Eng 24(12):2613–2621

Hull JC (2006) Options, futures, and other derivatives. Pearson Education India, Bengaluru

Ierapetritou MG, Pistikopoulos EN (1996) Batch plant design and operations under uncertainty. Ind Eng Chem Res 35(3):772–787

Iyer RR, Grossmann IE (1998) A bilevel decomposition algorithm for long-range planning of process networks. Ind Eng Chem Res 37(2):474–481

Jayaraman V, Pirkul H (2001) Planning and coordination of production and distribution facilities for multiple commodities. Eur J Oper Res 133(2):394–408

Jiang Y et al (2017) Production planning problems with joint service-level guarantee: a computational study. Int J Prod Res 55(1):38–58

Johns W, Marketos G, Rippin D (1978) The optimal design of chemical plant to meet time-varying demands in the presence of technical and commercial uncertainty. Trans Inst Chem Eng 56:249

Kalchschmidt M, Zotteri G, Verganti R (2003) Inventory management in a multi-echelon spare parts supply chain. Int J Prod Econ 81:397–413

Karimi IA, McDonald CM (1997) Planning and scheduling of parallel semicontinuous processes. 2. Short-term scheduling. Ind Eng Chem Res 36(7):2701–2714

Khemiri R, Elbedoui-Maktouf K, Grabot B, Zouari B (2017) A fuzzy multi-criteria decision-making approach for managing performance and risk in integrated procurement–production planning. Int J Prod Res 55(18):5305–5329

Kirchoff JF, Tate WL, Mollenkopf DA (2016) The impact of strategic organizational orientations on green supply chain management and firm performance. Int J Phys Distrib Logist Manag 46(3):269–292

Krasko V, Rebennack S (2017) Two-stage stochastic mixed-integer nonlinear programming model for post-wildfire debris flow hazard management: mitigation and emergency evacuation. Eur J Oper Res 263(1):265–282

Kumar M, Vrat P, Shankar R (2004) A fuzzy goal programming approach for vendor selection problem in a supply chain. Comput Ind Eng 46(1):69–85

Lee BK, Kang KH, Lee YH (2008) Decomposition heuristic to minimize total cost in a multi-level supply chain network. Comput Ind Eng 54(4):945–959

Liang T-F (2008) Fuzzy multi-objective production/distribution planning decisions with multi-product and multi-time period in a supply chain. Comput Ind Eng 55(3):676–694

Lim MK, Tseng M-L, Tan KH, Bui TD (2017) Knowledge management in sustainable supply chain management: improving performance through an interpretive structural modelling approach. J Clean Prod 162:806–816

Lin C-WR, Chen H-YS (2003) Dynamic allocation of uncertain supply for the perishable commodity supply chain. Int J Prod Res 41(13):3119–3138

Liu S, Kao C (2004) Solving fuzzy transportation problems based on extension principle. Eur J Oper Res 153(3):661–674

Liu ML, Sahinidis NV (1995) Computational trends and effects of approximations in an MILP model for process planning. Ind Eng Chem Res 34(5):1662–1673

Liu ML, Sahinidis NV (1996) Optimization in process planning under uncertainty. Ind Eng Chem Res 35(11):4154–4165

Lu Z, Bostel N (2007) A facility location model for logistics systems including reverse flows: the case of remanufacturing activities. Comput Oper Res 34(2):299–323

Luenberger DG (1997) Investment science. OUP Catalogue

Majidi-Qadikolai M, Baldick R (2016) Stochastic transmission capacity expansion planning with special scenario selection for integrating $ N − 1$ contingency analysis. IEEE Trans Power Syst 31(6):4901–4912

Mangla SK, Kumar P, Barua MK (2014) Flexible decision approach for analysing performance of sustainable supply chains under risks/uncertainty. Glob J Flex Syst Manag 15(2):113–130

Mason SP, Merton RC (1985) The role of contingent claims analysis in corporate finance. In: Altman EI, Subrahmanyam MG (eds) Recent advances in corporate finance. Richard D. Irwin, Homewood

McDonald CM, Karimi IA (1997) Planning and scheduling of parallel semicontinuous processes. 1. Production planning. Ind Eng Chem Res 36(7):2691–2700

Minguez R, García-Bertrand R, Arroyo JM, Alguacil N (2017) On the solution of large-scale robust transmission network expansion planning under uncertain demand and generation capacity. IEEE Trans Power Syst 33(2):1242–1251

Myers SC (1984) Finance theory and financial strategy. Interfaces 14(1):126–137

Nemhauser GL, Wolsey LA (1988) Integer and combinatorial optimization. Wiley, New York, p 118

Nobil AH, Niaki STA, Cárdenas-Barrón LE (2017) Some observations on “location and allocation decisions for multi-echelon supply chain network: a multi-objective evolutionary approach”. Int J Appl Comput Math 3(2):1561–1563

Norton LC, Grossmann IE (1994) Strategic planning model for complete process flexibility. Ind Eng Chem Res 33(1):69–76

O’Driscoll PJ (2017) A modern two-stage stochastic programming portfolio model for an oil refinery with financial risk management. Int J Oper Res 28(1):121–140

Oelze N et al (2016) Sustainable development in supply chain management: the role of organizational learning for policy implementation. Bus Strategy Environ 25(4):241–260

Olivares-Benitez E, González-Velarde JL, Ríos-Mercado RZ (2012) A supply chain design problem with facility location and bi-objective transportation choices. Top 20(3):729–753

Papageorgiou LG, Pantelides CC (1996) Optimal campaign planning/scheduling of multipurpose batch/semicontinuous plants. 1. Mathematical formulation. Ind Eng Chem Res 35(2):488–509

Peidro D et al (2009) Fuzzy optimization for supply chain planning under supply, demand and process uncertainties. Fuzzy Sets Syst 160(18):2640–2657

Petkov SB, Maranas CD (1997) Multiperiod planning and scheduling of multiproduct batch plants under demand uncertainty. Ind Eng Chem Res 36(11):4864–4881

Petkov SB, Maranas CD (1998) Design of single-product campaign batch plants under demand uncertainty. AIChE J 44(4):896–911

Petrovic D, Roy R, Petrovic R (1999) Supply chain modelling using fuzzy sets. Int J Prod Econ 59(1):443–453

Pishvaee MS, Torabi SA (2010) A possibilistic programming approach for closed-loop supply chain network design under uncertainty. Fuzzy Sets Syst 161(20):2668–2683

Pistikopoulos E, Ierapetritou M (1995) Novel approach for optimal process design under uncertainty. Comput Chem Eng 19(10):1089–1110

Rakowski D, Shirley SE, Stark JR (2017) Tail-risk hedging, dividend chasing, and investment constraints: the use of exchange-traded notes by mutual funds. J Emp Financ 44:91–107

Rau H, Wu M-Y, Wee H-M (2003) Integrated inventory model for deteriorating items under a multi-echelon supply chain environment. Int J Prod Econ 86(2):155–168

Reinhart H-J (1987) Design of flexible multi-product plants: a new procedure for optimal equipment sizing under uncertainty. AIChE, New York

Rezaee A et al (2017) Green supply chain network design with stochastic demand and carbon price. Ann Oper Res 250(2):463–485

Ritchken P, Rabinowitz G (1988) Capital budgeting using contingent claims analysis: a tutorial. Adv Futures Options Res 3:119–143

Sahinidis N, Grossmann IE (1991a) MINLP model for cyclic multiproduct scheduling on continuous parallel lines. Comput Chem Eng 15(2):85–103

Sahinidis N, Grossmann IE (1991b) Multiperiod investment model for processing networks with dedicated and flexible plants. Ind Eng Chem Res 30(6):1165–1171

Sahinidis N, Grossmann IE (1991c) Reformulation of multiperiod MILP models for planning and scheduling of chemical processes. Comput Chem Eng 15(4):255–272

Sahinidis N, Grossmann IE (1992) Reformulation of the multiperiod MILP model for capacity expansion of chemical processes. Oper Res 40(1-supplement-1):S127–S144

Sahinidis N et al (1989) Optimization model for long range planning in the chemical industry. Comput Chem Eng 13(9):1049–1063

Sakawa M (1993) Fuzzy sets and interactive multiobjective optimization. Plenum Press, New York

Schachter J (2016) A real options approach to valuing flexibility in demand-side response operations and investments under uncertainty. The University of Manchester, Manchester

Shah N, Pantelides CC (1992) Design of multipurpose batch plants with uncertain production requirements. Ind Eng Chem Res 31(5):1325–1337

Shah N, Pantelides C, Sargent R (1993) A general algorithm for short-term scheduling of batch operations—II. Computational issues. Comput Chem Eng 17(2):229–244

Snyder LV et al (2016) OR/MS models for supply chain disruptions: a review. IIE Trans 48(2):89–109

Sox CR et al (1999) A review of the stochastic lot scheduling problem. Int J Prod Econ 62(3):181–200

Straub DA, Grossmann IE (1990) Integrated stochastic metric of flexibility for systems with discrete state and continuous parameter uncertainties. Comput Chem Eng 14(9):967–985

Straub DA, Grossmann IE (1993) Design optimization of stochastic flexibility. Comput Chem Eng 17(4):339–354

Subrahmanyam S, Pekny JF, Reklaitis GV (1994) Design of batch chemical plants under market uncertainty. Ind Eng Chem Res 33(11):2688–2701

Swanson D et al (2017) Applying theories from other disciplines to logistics and supply chain management: a systematic literature review. Transp J 56(3):299–356

Syarif A, Yun Y, Gen M (2002) Study on multi-stage logistic chain network: a spanning tree-based genetic algorithm approach. Comput Ind Eng 43(1):299–314

Tavakkoli-Moghaddam R et al (2010) A location within distribution network design problem with flexibility demand. In: Proceeding of world congress on engineering, London

Tiwari R, Dharmahr S, Rao J (1987) Fuzzy goal programming an additive model. Fuzzy Sets Syst 24:27–34

Torabi SA, Hassini E (2008) An interactive possibilistic programming approach for multiple objective supply chain master planning. Fuzzy Sets Syst 159(2):193–214

Torabi S, Hassini E (2009) Multi-site production planning integrating procurement and distribution plans in multi-echelon supply chains: an interactive fuzzy goal programming approach. Int J Prod Res 47(19):5475–5499

Triantis A, Borison A (2001) Real options: state of the practice. J Appl Corp Finance 14(2):8–24

Trigeorgis L (1996) Real options: managerial flexibility and strategy in resource allocation. MIT Press, Cambridge

Tsiakis P, Papageorgiou LG (2008) Optimal production allocation and distribution supply chain networks. Int J Prod Econ 111(2):468–483

Tsiakis P, Shah N, Pantelides CC (2001) Design of multi-echelon supply chain networks under demand uncertainty. Ind Eng Chem Res 40(16):3585–3604

van der Heijden MC (1999) Multi-echelon inventory control in divergent systems with shipping frequencies. Eur J Oper Res 116(2):331–351

Verbiest F, Cornelissens T, Springael J (2017) Design of a chemical batch plant with parallel production lines: plant configuration and cost effectiveness. Comput Chem Eng 99:21–30

Wang R-C, Liang T-F (2005) Applying possibilistic linear programming to aggregate production planning. Int J Prod Econ 98(3):328–341

Wang G et al (2016) Big data analytics in logistics and supply chain management: certain investigations for research and applications. Int J Prod Econ 176:98–110

Wellons HS, Reklaitis G (1989) The design of multiproduct batch plants under uncertainty with staged expansion. Comput Chem Eng 13(1–2):115–126

Xueya Z, Sargent R (1996) The optimal operation of mixed production facilities—extensions and improvements. Comput Chem Eng 20:S1287–S1293

Yao M, Minner S (2017) Review of multi-supplier inventory models in supply chain management: an update. Available at SSRN 2995134

Zegordi SH, Eskandarpour M (2010) Reverse logistic network design with fuzzy demand of return products. In: The 10th Iranian conference on fuzzy systems. Shahid Beheshti University, Tehran

Zentner M et al (1994) Practical considerations in using model-based optimization for the scheduling and planning of batch/semicontinuous processes. J Process Control 4(4):259–280

Zhang X, Sargent R (1996) The optimal operation of mixed production facilities—a general formulation and some approaches for the solution. Comput Chem Eng 20(6–7):897–904

Zhu Q et al (2017) A comparison of regulatory awareness and green supply chain management practices among Chinese and Japanese manufacturers. Bus Strategy Environ 26(1):18–30

Acknowledgements

The author acknowledges the funding support of the Babol Noshirvani University of Technology through Grant Program No. BNUT/390063/98.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Human and animal rights

This article does not contain any studies with human or animal subjects.

Informed consent

None.

Additional information

Communicated by V. Loia.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arasteh, A. Supply chain management under uncertainty with the combination of fuzzy multi-objective planning and real options approaches. Soft Comput 24, 5177–5198 (2020). https://doi.org/10.1007/s00500-019-04271-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-019-04271-1