Abstract

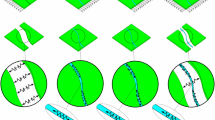

The interface between constituents of a multiphase material exhibits properties different from those of the bulk and can lead to major alternation of the material response. Interface effects are particularly important for multiphase nano-materials where the area-to-volume ratio is significantly large. In this contribution, we study the influence of a degrading general interface. That is, we allow for the initiation and accumulation of damage on a generalized interface accounting for both jumps of the displacement and the traction across the interface. The applicability of the proposed framework is demonstrated through several numerical examples. We present a parametric study on the influence of a broad range of interface material parameters on the overall behavior of various microstructures subject to volumetric loading and unloading. The numerical results illustrate that the resistance along the interface plays a key role in the resulting damage mechanism and could potentially prevent the detachment of the inclusion from the matrix regardless of the resistance across the interface or bulk material parameters. This behavior is observed and shown for both two- and three-dimensional examples. Moreover, the size-effect due to the general interface model is examined and compared against other interface models. Finally, the influence of the boundary conditions on the effective response and damage initiation of several microstructures is studied.

Similar content being viewed by others

References

Sharma P, Ganti S (2004) Size-dependent Eshelby’s tensor for embedded nano-inclusions incorporating surface/interface energies. J Appl Mech 71(5):663–671

Dingreville R, Qu J, Cherkaoui M (2005) Surface free energy and its effect on the elastic behavior of nano-sized particles, wires and films. J Mech Phys Solids 53(8):1827–1854

He J, Lilley CM (2008) Surface effect on the elastic behavior of static bending nanowires. Nano Lett 8:1798–1802

Mogilevskaya SG, Crouch SL, Stolarski HK (2008) Multiple interacting circular nano-inhomogeneities with surface/interface effects. J Mech Phys Solids 56(6):2298–2327

Cheng YT, Verbrugge MW (2008) The influence of surface mechanics on diffusion induced stresses within spherical nanoparticles. J Appl Phys 104(8):083521

Wang ZQ, Zhao YP, Huang ZP (2010) The effects of surface tension on the elastic properties of nano structures. Int J Eng Sci 48(2):140–150

Ansari R, Sahmani S (2011) Bending behavior and buckling of nanobeams including surface stress effects corresponding to different beam theories. Int J Eng Sci 49(11):1244–1255

Altenbach H, Eremeyev VA (2011) On the shell theory on the nanoscale with surface stresses. Int J Eng Sci 49(12):1294–1301

Park H (2012) Surface stress effects on the critical buckling strains of silicon nanowires. Comput Mater Sci 51:396–401

Nanthakumar SS, Valizadeh N, Park HS, Rabczuk T (2015) Surface effects on shape and topology optimization of nanostructures. Comput Mech 56:97–112

Cordero NM, Forest S, Busso EP (2016) Second strain gradient elasticity of nano-objects. J Mech Phys Solids 97:92–124

Chatzigeorgiou G, Meraghni F, Javili A (2017) Generalized interfacial energy and size effects in composites. J Mech Phys Solids 106:257–282

Barenblattm GI (1962) The mathematical theory of equilibrium cracks in brittle fracture. Adv Appl Mech 7:55–129

Hillerborg A, Modéer M, Petersson P-E (1976) Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem Concrete Res 6:773–781

Xu X-P, Needleman A (1994) Numerical simulations of fast crack growth in brittle. J Mech Phys Solids 42:1397–1434

Ortiz M, Pandolfi A (1999) Finite-deformation irreversible cohesive elements for three-dimensional crack-propagation analysis. Int J Numer Methods Eng 44:1267–1282

Javili A (2018) A note on traction continuity across an interface in a geometrically non-linear framework. Math Mech Solids. https://doi.org/10.1177/1081286518766980

Wells GN, Sluys LJ (2001) A new method for modelling cohesive cracks using finite elements. Int J Numer Methods Eng 50:2667–2682

Remmers JJC, de Borst R, Needleman A (2003) A cohesive segments method for the simulation of crack growth. Comput Mech 31:69–77

Zhou F, Molinari JF (2003) Dynamic crack propagation with cohesive elements: a methodology to address mesh dependency. Int J Numer Methods Eng 59:1–24

Mergheim J, Kuhl E, Steinmann P (2005) A finite element method for the computational modelling of cohesive cracks. Int J Numer Methods Eng 63:276–289

van den Bosch MJ, Schreurs PJG, Geers MGD (2006) An improved description of the exponential Xu and Needleman cohesive zone law for mixed-mode decohesion. Eng Fract Mech 73:1220–1234

van den Bosch MJ, Schreurs PJG, Geers MGD (2007) On the development of a 3d cohesive zone element in the presence of large deformations. Comput Mech 42:171–180

Terada K, Ishii T, Kyoya T, Kishino Y (2007) Finite cover method for progressive failure with cohesive zone fracture in heterogeneous solids and structures. Comput Mech 191–210:2007

Ural A, Krishnan VR, Papoulia KD (2009) A cohesive zone model for fatigue crack growth allowing for crack retardation. Int J Solids Struct 46:2453–2462

Park K, Paulino GH, Roesler JR (2009) A unified potential-based cohesive model of mixed-mode fracture. J Mech Phys Solids 57:891–908

Yang QD, Fang XJ, Shi JX, Lua J (2010) An improved cohesive element for shell delamination analyses. Int J Numer Methods Eng 83:611–641

Needleman A (2014) Some issues in cohesive surface modeling. Proc IUTAM 10:221–246

Dimitri R, De Lorenzis L, Wriggers P, Zavarise G (2014) NURBS- and T-spline-based isogeometric cohesive zone modeling of interface debonding. Comput Mech 54:369–388

Moeckel GP (1975) Thermodynamics of an interface. Arch Ration Mech Anal 57:255–280

Murdoch AI (1976) A thermodynamical theory of elastic material interfaces. Q J Mech Appl Math 29(3):245–275

dell’Isola F, Romano A (1987) On the derivation of thermomechanical balance equations for continuous systems with a nonmaterial interface. Int J Eng Sci 25:1459–1468

Fried E, Gurtin ME (2007) Thermomechanics of the interface between a body and its environment. Contin Mech Thermodyn 19:253–271

Javili A, Ottosen NS, Ristinmaa M, Mosler J (2017a) Aspects of interface elasticity theory. Math Mech Solids 23:1004–1024

Gurtin ME, Murdoch AI (1975) A continuum theory of elastic material surfaces. Arch Ration Mech Anal 57(4):291–323

Duan HL, Wang J, Karihaloo BL (2009) Theory of elasticity at the nanoscale. Adv Appl Mech 42:1–68

Javili A, McBride A, Steinmann P (2013a) Thermomechanics of solids with lower-dimensional energetics: on the importance of surface, interface, and curve structures at the nanoscale. A unifying review. Appl Mech Rev 65:010802

Hashin Z (2002) Thin interphase/imperfect interface in elasticity with application to coated fiber composites. J Mech Phys Solids 50:2509–2537

Benveniste Y, Miloh T (2003) Imperfect soft and stiff interfaces in two-dimensional elasticity. Mech Mater 33:309–323

Steinmann P, Häsner O (2005) On material interfaces in thermomechanical solids. Arch Appl Mech 75:31–41

Monchiet V, Bonnet G (2010) Interfacial models in viscoplastic composites materials. Int J Eng Sci 48:1762–1768

Javili A, Steinmann P, Mosler J (2017b) Micro-to-macro transition accounting for general imperfect interfaces. Comput Methods Appl Mech Eng 317:274–317

Javili A (2017) Variational formulation of generalized interfaces for finite deformation elasticity. Math Mech Solids 23:1303–1322

Heitbreder T, Ottosen NS, Ristinmaa M, Mosler J (2018) On damage modeling of material interfaces: Numerical implementation and computational homogenization. Comput Methods Appl Mech Eng 337:1–27

Javili A, Kässmair S, Steinmann P (2014a) General imperfect interfaces. Comput Methods Appl Mech Eng 275:76–97

Esmaeili A, Javili A, Steinmann P (2017) Coupled thermally general imperfect and mechanically coherent energetic interfaces subject to in-plane degradation. J Mech Mater Struct 12:289–312

Pavanello F, Manca F, Luca Palla P, Giordano S (2012) Generalized interface models for transport phenomena: unusual scale effects in composite nanomaterials. J Appl Phys 112:084306

Miehe C, Koch A (2002) Computational micro-to-macro transitions of discretized microstructures undergoing small strains. Arch Appl Mech 72:300–317

Guidault PA, Allix O, Champaney L, Navarro JP (2007) A two-scale approach with homogenization for the computation of cracked structures. Comput Struct 85:1360–1371

Danas K, Idiart MI, Ponte Castañeda P (2008) A homogenization-based constitutive model for isotropic viscoplastic porous media. Int J Solids Struct 45:3392–3409

Hain M, Wriggers P (2008) Computational homogenization of micro-structural damage due to frost in hardened cement paste. Finite Elem Anal Des 44:233–244

Inglis HM, Geubelle PH, Matouš K (2008) Boundary condition effects on multiscale analysis of damage localization. Philos Mag 88:2373–2397

Temizer İ, Wriggers P (2008) On the computation of the macroscopic tangent for multiscale volumetric homogenization problems. Comput Methods Appl Mech Eng 198:495–510

Özdemir I, Brekelmans WAM, Geers MGD (2008) \(\text{ FE }^{2}\) computational homogenization for the thermo-mechanical analysis of heterogeneous solids. Comput Methods Appl Mech Eng 198:602–613

Geers MGD, Kouznetsova VG, Brekelmans WAM (2010) Multi-scale computational homogenization: trends and challenges. J Comput Appl Math 234:2175–2182

Terada K, Kurumatani M, Ushida T, Kikuchi N (2010) A method of two-scale thermo-mechanical analysis for porous solids with micro-scale heat transfer. Comput Mech 46:269–285

Larsson F, Runesson K, Saroukhani S, Vafadari R (2011) Computational homogenization based on a weak format of micro-periodicity for RVE-problems. Comput Methods Appl Mech Eng 200:11–26

Coenen EWC, Kouznetsova VG, Bosco E, Geers MGD (2012) A multi-scale approach to bridge microscale damage and macroscale failure: a nested computational homogenization-localization framework. Int J Fract 178:157–178

Kochmann DM, Venturini GN (2013) Homogenized mechanical properties of auxetic composite materials in finite-strain elasticity. Smart Mater Struct 22:084004

Javili A, Chatzigeorgiou G, Steinmann P (2013b) Computational homogenization in magneto-mechanics. Int J Solids Struct 50:4197–4216

Bosco E, Kouznetsova VG, Geers MGD (2015) Multi-scale computational homogenization-localization for propagating discontinuities using X-FEM. Int J Numer Methods Eng 102:496–527

Cong Y, Nezamabadi S, Zahrouni H, Yvonnet J (2015) Multiscale computational homogenization of heterogeneous shells at small strains with extensions to finite displacements and buckling. Int J Numer Methods Eng 104:235–259

Alberdi R, Zhang G, Khandelwal K (2018) A framework for implementation of RVE based multiscale models in computational homogenization using isogeometric analysis. Int J Numer Methods Eng 114:1018–1051

Eidel B, Fischer A (2018) The heterogeneous multiscale finite element method for the homogenization of linear elastic solids and a comparison with the FE2 method. Comput Methods Appl Mech Eng 329:332–368

Kanouté P, Boso DP, Chaboche JL, Schrefler BA (2009) Multiscale methods for composites: a review. Arch Comput Methods Eng 16:31–75

Charalambakis N (2010) Homogenization techniques and micromechanics. A survey and perspectives. Appl Mech Rev 63:030803

Saeb S, Steinmann P, Javili A (2016) Aspects of computational homogenization at finite deformations: a unifying review from reuss’ to voigt’s bound. Appl Mech Rev 68(5):050801

Matouš K, Geers MGD, Kouznetsova VG, Gillman A (2017) A review of predictive nonlinear theories for multiscale modeling of heterogeneous materials. J Comput Phys 330:192–220

Greer JR, Oliver WC, Nix WD (2005) Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater 53:1821–1830

Taloni A, Vodret M, Costantini G, Zapperi S (2018) Size effects on the fracture of microscale and nanoscale materials. Nat Rev Mater 3:211–224

Kouznetsova VG, Geers MGD, Brekelmans WAM (2004) Multi-scale second-order computational homogenization of multi-phase materials: a nested finite element solution strategy. Comput Methods Appl Mech Eng 193:5525–5550

Kaczmarczyk L, Pearce CJ, Bićanić N (2008) Scale transition and enforcement of RVE boundary conditions in second-order computational homogenization. Int J Numer Methods Eng 74:506–522

Matouš K, Geubelle PH (2005) Multiscale modelling of particle debonding in reinforced elastomers subjected to finite deformations. Int J Numer Methods Eng 65:190–223

Fritzen F, Leuschner M (2015) Nonlinear reduced order homogenization of materials including cohesive interfaces. Comput Mech 56:131–151

Spring DW, Paulino GH (2015) Computational homogenization of the debonding of particle reinforced composites: the role of interphases in interfaces. Comput Mater Sci 109:209–224

Toro S, Sánchez PJ, Blanco PJ, de Souza Neto EA, Huespe AE, Feijóo RA (2016) Multiscale formulation for material failure accounting for cohesive cracks at the macro and micro scales. Int J Plast 76:75–110

Yvonnet J, Quang H Le, He Q-C (2008) An XFEM/level set approach to modelling surface/interface effects and to computing the size-dependent effective properties of nanocomposites. Comput Mech 42(1):119–131

Javili A, Chatzigeorgiou G, McBride A, Steinmann P, Linder C (2015) Computational homogenization of nano-materials accounting for size effects via surface elasticity. GAMM Mitteilungen 38:285–312

Wilmers J, McBride A, Bargmann S (2017) Interface elasticity effects in polymer-filled nanoporous metals. J Mech Phys Solids 99:163–177

McBride A, Mergheim J, Javili A, Steinmann P, Bargmann S (2012) Micro-to-macro transitions for heterogeneous material layers accounting for in-plane stretch. J Mech Phys Solids 60:1221–1239

Dargazany R, Itskov M (2013) Constitutive modeling of the mullins effect and cyclic stress softening in filled elastomers. Phys Rev E 88:012602

Bueche F (1961) Mullins effect and rubber–filler interaction. Appl Polym 5:271–281

Kilian HG, Strauss M, Hamm W (1994) Universal properties in filler-loaded rubbers. Rubber Chem Technol 67:1–16

Govindjee S, Simo J (1992) Transition from micro-mechanics to computationally efficient phenomenology: Carbon black filled rubbers incorporating Mullins’ effect. Journal of the Mechanics and Physics of Solids 40:213–233

Ogden RW, Roxburgh DG (1999) A pseudo-elastic model for the Mullins effect in filled rubber. Proc R Soc A Math Phys Eng Sci 455:2861–2877

Dorfmann A, Ogden RW (2004) A constitutive model for the Mullins effect with permanent set in particle-reinforced rubber. Int J Solids Struct 41:1855–1878

Dorfmann A, Pancheri FQ (2012) A constitutive model for the Mullins effect with changes in material symmetry. Int J Non-Linear Mech 47:874–887

Nguyen VP, Stroeven M, Sluys LJ (2011) Multiscale continuous and discontinuous modelling of heterogeneous materials: a review on recent developments. J Multiscale Model 3:229–270

Inglis HM, Geubelle PH, Matous K, Tan H, Huang Y (2007) Cohesive modeling of dewetting in particulate composites: micromechanics vs. multiscale finite element analysis. Mech Mater 39:580–595

Moraleda J, Segurado J, Llorca J (2009) Effect of interface fracture on the tensile deformation of fiber-reinforced elastomers. Int J Solids Struct 46:4287–4297

Javili A, McBride A, Steinmann P, Reddy B (2014b) A unified computational framework for bulk and surface elasticity theory: a curvilinear-coordinate-based finite element methodology. Comput Mech 54:745–762

Crisfield MA (1983) An arc-length method including line searches and accelerations. Int J Numer Methods Eng 19:1269–1289

Fafard M, Massicotte B (1991) Geometrical interpretation of the arc-length method. Comput Struct 46:603–615

Wriggers P (2008) Nonlinear finite elements methods. Springer, Berlin

Javili A, Saeb S, Steinmann P (2016) Aspects of implementing constant traction boundary conditions in computational homogenization via semi-dirichlet boundary conditions. Comput Mech 59:1–15

Firooz S, Saeb S, Chatzigeorgiou G, Meraghni F, Steinmann P, Javili A (2019) Systematic study of homogenization and the utility of circular simplified representative volume element. Math Mech Solids. https://doi.org/10.1177/1081286518823834

Javili A, McBride A, Steinmann P, Reddy B (2012) Relationships between the admissible range of surface material parameters and stability of linearly elastic bodies. Philos Mag 92(28–30):3540–3563

Nakamura Y, Yamaguchi M, Okubo M, Matsumoto T (1992) Effect of particle size on the fracture toughness of epoxy resin filled with spherical silica. Polymer 33:3415–3426

Rae PJ, Goldrein HT, Palmer SJP, Field JE, Lewis AL (2002) Quasi-static studies of the deformation and failure of \(\beta \)-HMX based polymer bonded explosives. Proc R Soc Lond A 458:743–762

Allan Zhong X, Knaus WG (2000) Mechanics of composite materials and structures. Mech Compos Mater Struct 7:35–53

Acknowledgements

The support of this work by the Cluster of Excellence “Engineering of Advanced Materials” at the University of Erlangen–Nuremberg, funded by the DFG within the framework of its “Excellence Initiative”, is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saeb, S., Steinmann, P. & Javili, A. On effective behavior of microstructures embedding general interfaces with damage. Comput Mech 64, 1473–1494 (2019). https://doi.org/10.1007/s00466-019-01727-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-019-01727-x