Abstract

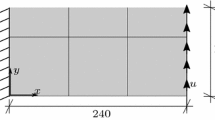

This contribution deals with a computational model for a shape memory alloy fiber composite. Three main topics have been considered within the presented model. First, a 1D fiber model is derived which accounts for all relevant nonlinear material phenomena of shape memory alloys. These are pseudoelasticity in the high temperature range and pseudoplasticity in the low temperature range. The latter is closely connected to the shape memory effect. The constrained and two-way shape memory effect are captured as well. Second, the shape memory fiber model is implemented into the finite element method. Two different structural elements are derived which lead to two different discretization schemes. A non-conform meshing concept and a conform meshing concept are presented. Randomly oriented and distributed fibers are considered. Both schemes are compared within the paper. Third, an \(\hbox {FE}^{2}\) ansatz is presented. The computational homogenization process makes the detailed description of the complicated fiber-structure on macro-level dispensable. The micro-structure is considered in a representative volume element. It captures the main characteristics of the multi-functional composite. Finally, numerical examples present the capability of the formulation.

Similar content being viewed by others

References

McCormick J, DesRoches R, Fugazza D, Auricchio F (2006) Seismic vibration control using superelastic shape memory alloys. J Eng Mater-T ASME 128:294

Castellano M, Colato G, Infanti S (2004) Use of viscous dampers and shock transmission units in the seismic protection of buildings. In: Proceedings of 13th world conference on earthquake engineering, pp. 1–15. Paper No. 2172

Indirli M, Castellano M, Clemente P, Martelli A (2001) Demo-application of shape memory alloy devices: the rehabilitation of the S. Giorgio Church bell tower. In: Liu SC (ed) Smart structures and materials 2001: Smart systems for bridges, structures, and highways, society of photo-optical instrumentation engineers (SPIE) conference series, vol 4330, Society of photo-optical instrumentation engineers (SPIE) conference series, vol 4330, pp. 262–272

Indirli M, Spadoni B, Carni R, Clemente C, Martelli A, Castellano M (2008) Shape memory alloy devices for the structural improvement of masonry heritage structures. Int J Archit Herit 2:93

Song G, Ma N, Li HN (2006) Applications of shape memory alloys in civil structures. Eng Struct 28:1266

Moser K, Bergamini A, Christen R, Czaderski C (2005) Feasibility of concrete prestressed by shape memory alloy short fibers. Mater Struct 38:593

Janke L, Czaderski C, Motavalli M, Ruth J (2005) Formgedächtnislegierungen in Ingenieurstrukturen des Stahlbetonbaues: Materialphänomene, Anwendungskonzepte und Visionen. Mater Struct 38(279):578

Klinkel S, Kohlhaas B (2011) Modellierung und Anwendung von Formgedächtnislegierungen im Bauwesen. Bauingenieur-germany Jahresausgabe 2011/2012:101

Achenbach M, Müller I (1982) A model for shape memory. J Phys Paris 43(C4):163

Seelecke S, Müller I (2004) Shape memory alloy actuators in smart structures: modeling and simulation. Appl Mech Rev 57:23

Brinson L (1993) One-dimensional behavior of shape memory alloys: thermomechanical derivation with non-constant material functions and redefined martensite internal variable. J Intel Mater Syst Struct 4:229

Leclercq S, Lexcellent C (1996) A general macroscopic description of the thermomechanical behavior of shape memory alloys. J Mech Phys Solids 44(6):953

Raniecki B, Lexcellent C (1998) Thermodynamics of isotropic pseudoelasticity in shape memory alloys. Eur J Mech A Solid 17:185

Bo Z, Lagoudas D (1999) Thermomechanical modeling of polycrystalline {SMAs} under cyclic loading, Part I: theoretical derivations. Int J Eng Sci 37(9):1089

Lagoudas D, Bo Z (1999) Thermomechanical modeling of polycrystalline {SMAs} under cyclic loading, Part II: material characterization and experimental results for a stable transformation cycle. Int J Eng Sci 37(9):1141

Bo Z, Lagoudas D (1999) Thermomechanical modeling of polycrystalline {SMAs} under cyclic loading, Part III: evolution of plastic strains and two-way shape memory effect. Int J Eng Sci 37(9):1175

Bo Z, Lagoudas D (1999) Thermomechanical modeling of polycrystalline {SMAs} under cyclic loading, Part IV: modeling of minor hysteresis loops. Int J Eng Sci 37(9):1205

Helm D (2001) Formgedächtnislegierungen: experimentelle Untersuchung, phänomenologische Modellierung und numerische Simulation der thermomechanischen Materialeigenschaften. Ph.D. thesis, Universität Gesamthochschule Kassel

Helm D, Haupt P (2003) Shape memory behaviour: modelling within continuum thermomechanics. Int J Solids Struct 40:827

Helm D (2007) Numerical simulation of martensititc phase transitions in shape memory alloys using an improved integration algorithm. Int J Numer Methods Eng 69:1997

Helm D (2007) Thermomechanics of martensititc phase transformations in shape memory alloys – I. Constitutive theories for small and large deformations. J Mech Mater Struct 2:87

Christ D, Reese S (2008) Thermomechanically coupled modelling of shape memory alloys in the framework of large strains. GAMM-Mitteilungen 31(2):176

Christ D, Reese S (2009) A finite element model for shape memory alloys considering thermomechanical couplings at large strains. Int J Solids Struct 46:3694

Christ D (2009) Thermomechanical modelling of shape memory alloy structures in medical applications. Ph.D. thesis, Technische Universität Braunschweig

Lagoudas D (2008) Shape memory alloys: modeling and engineering applications. Springer, Boston

Evangelista V, Marfia S, Sacco E (2009) Phenomenological 3D and 1D consistent models for shape-memory alloy materials. Comput Mech 44(3):405

Khandan R, Mahzoon M, Fazelzadeh S, Ali H (2009) A consistent approach for deriving a 1D constitutive equation for shape memory alloys. Smart Mater Struct 18(9):1

Aboudi J, Freed Y (2006) Two-way thermomechanically coupled micromechanical analysis of shape memory alloy composites. J Mech 1:937

Armstrong W, Kino H (1995) Martensitic transformations in a NiTi fiber reinforced 6061 aluminium matrix composite. J Intel Mater Syst Struct 6:809

Boyd J, Lagoudas D (1996) A thermodynamical constitutive model for shape memory materials—Part I: The monolithic shape memory alloy. Int J Plast 12(7):843

Carvelli V, Taliercio A (1999) A micromechanical model for the analysis of unidirectional elastoplastic composites subjected to 3D stresses. Mech Res Commun 26(5):547

Cherkaoui M, Sun Q, Song G (2000) MIcromechanics modeling of composite with ductile matrix and shape memory alloy reinforcement. Int J Solids Struct 37:1577

Notta-Cuvier D, Lauro F, Bennani B, Balieu R (2013) An efficient modelling of inelastic composites with misaligned short fibres. Int J Solids Struct 50:2857

Freed Y, Aboudi J (2008) Micromechanical investigation of plasticity-damage coupling of concrete reinforced by shape memory alloy fibers. Smart Mater Struct 17:1

Gilat R, Aboudi J (2004) Dynamic response of active composite plates: shape memory fibers in polymeric/metallic matrices. Int J Solids Struct 41:5717

Kawai M, Ogawa H, Baburaj V, Koga T (1999) Micromechanical analysis for hysteretic behavior of unidirectional TiNi SMA fiber composites. J Intel Mater Syst Struct 10:14

Klinkel S, Sansour C, Wagner W (2005) An anisotropic fibre-matrix material model at finite elastic–plastic strains. Comput Mech 35:409

Marfia S (2005) Micro-macro analysis of shape memory alloy composites. Int J Solids Struct 42:3677

Song G, Cherkaoui M, Sun Q (1999) Role of microstructure in the thermomechanical behavior of SMA composites. J Eng Mater-T ASME 121(1):86

Gebbeken N (1996) Zur Untersuchung des linearen Tragverhaltens von Verbundkonstruktionen mittels numerischer Methoden. Technical Report 96/1, Universität der Bundeswehr München

Huber F (2006) Nichtlineare dreidimensionale Modellierung von Beton- und Stahlbetontragwerken. Ph.D. thesis, Universität Stuttgart

Miehe C, Schröder J, Schotte J (1999) Computational homogenization analysis in finite plasticity simulation of texture development in polycrystalline materials. Comput Method Appl Mech 171(3–4):387

Geers M, Coenen E, Kouznetsova V (2007) Multi-scale computational homogenization of structured thin sheets. Model Simul Mater Sci 15(4):S393

Oskay C, Fish J (2007) Eigendeformation-based reduced order homogenization for failure analysis of heterogeneous materials. Comput Method Appl Mech 196(7):1216

Gruttmann F, Wagner W (2013) A coupled two-scale shell model with applications to layered structures. Int J Numer Method Eng 94(13):1233

Simo J, Hughes T (2000) Computational inelasticity, interdisciplinary applied mathematics mechanics and materials, vol 7. Springer, New York

Neunzert H, Blickensdörfer-Ehlers A (1998) Analysis, 3rd edn. Springer, Berlin

Juhász L (2004) Herleitung eines konstitutiven Modells für Formgedächtnislegierungen. Ph.D. thesis, Universität Karlsruhe

Zohdi T, Wriggers P (2005) Introduction To computational micromechanics. Lecture Notes in applied and computational mechanics. Springer Verlag, Berlin Heidelberg

Hill R (1963) Elastic properties of reinforced solids: some theoretical principles. J Mech Phys Solids 11(5):357

Gross D, Seelig T (2001) Bruchmechanik: Mit einer Einführung in die Mikromechanik. Springer, Berlin. URL http://www.books.google.de/books?id=ySI3E0YoEMQC

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kohlhaas, B., Klinkel, S. An \(\hbox {FE}^{2}\) model for the analysis of shape memory alloy fiber-composites. Comput Mech 55, 421–437 (2015). https://doi.org/10.1007/s00466-014-1112-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-014-1112-3