Abstract

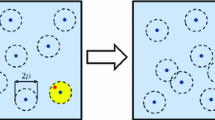

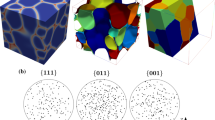

In this paper, an approach is identified using concepts in molecular dynamics (MD) and discrete element method (DEM) to generate the microstructure of polycrystalline materials. Using the proposed methods, different types of particles with different grain size and volume fraction in the real material, can be easily generated. It is assumed that the particles can be randomly packed together into a simulation region, by defining artificial interaction forces among them. Such forces may be either adopted from Van der Waals potential energy, or Hooke pair and gravity forces. The proposed method has proved to be fast due to the fact that the algorithm has been implemented on graphical processing units (GPU). Utilizing the Voronoi tessellation method, the set of the generated discrete grains have been altered to space-filling, adjoining polyhedrons with respect to the real geometry. Moreover, as an advantage, the boundary and the interface region of the microstructures were modeled.

Similar content being viewed by others

References

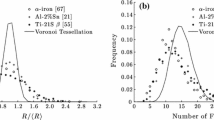

Fan Z, Wu Y, Zhao X, Lu Y (2004) Simulation of polycrystalline structure with Voronoi diagram in Laguerre geometry based on random closed packing of spheres. J Comput Mater Sci 29: 301–308

Weyer S, Frohlich A, Riesch-Oppermann H, Cizelj L, Kovac M (2002) Automatic finite element meshing of planar Voronoi tessellations. J Eng Fract Mech 69: 945–958

Quey R, Dawson PR, Barbe F (2011) Large-scale 3D random polycrystals for the finite element method: generation, meshing and remeshing. J Comput Methods Appl Mech Eng 200: 1729– 1745

Fritzen F, Bohlke T, Schnack E (2009) Periodic three-dimensional mesh generation for crystalline aggregates based on Voronoi tessellations. J Comput Mech 43: 701–713

Zhang KS, Wu MS, Feng R (2005) Simulation of microplasticity-induced deformation in uniaxially strained ceramics by 3-D Voronoi polycrystal modeling. J Plasticity 21: 801–834

Rycroft CH, Grest GS, Landry JW, Bazant MZ (2006) Analysis of granular flow in a pebble-bed nuclear reactor. Phys Rev E 74: 45–70

Luther T, Könke C (2009) Poly-crystal models for the analysis of inter-granular crack growth in metallic materials. J Eng Fract Mech 76: 2332–2343

NVIDIA GTX 480 product page (2012). http://www.geforce.com/hardware/desktop-gpus/geforce-gtx-480/specifications

van der Waals JH (1908) Lehrbuch der Thermodynamik, Mass and Van Suchtelen. Leipzig, Part 1

Silbert LE, Ertas D, Grest GS, Halsey TC, Levine D, Plimpton SJ (2001) Granular flow down an inclined plane: Bagnold scaling and rheology. Phys Rev E 64: 051302

Gellatly BJ, Finney JL (1982) Characterization of models of multi-component amorphous metals: the radical alternative to the Voronoi polyhedron. J Non-Cryst Solids 50: 319–329

Ziaei-Rad V, Nouri N, Ziaei-Rad S, Abtahi M (2012) A numerical study on mechanical performance of asphalt mixture using a meso-scale finite element model. J Finite Elem Anal Des 57: 81–91

Mo LT, Huurman M, Wu SP, Molenaar AAA (2008) 2D and 3D meso-scale finite element models for raveling analysis of porous asphalt concrete. J Finite Elem Anal Des 44: 186–196

Calcagnotto M, Ponge D, Demir E, Raabe D (2010) Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater Sci Eng A 527: 2738–2746

Ohata M, Suzuki M, Ui A, Minami F (2010) 3D-Simulation of ductile failure in two-phase structural steel with heterogeneous microstructure. Eng Fract Mech 77: 277–284

Nouri N, Ziaei-Rad S (2011) A molecular dynamics investigation on mechanical properties of cross-linked polymer networks. Macromolecules 44: 5481–5489

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Nouri, N., Ziaei-Rad, V. & Ziaei-Rad, S. An approach for simulating microstructures of polycrystalline materials. Comput Mech 52, 181–192 (2013). https://doi.org/10.1007/s00466-012-0805-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-012-0805-8