Abstract

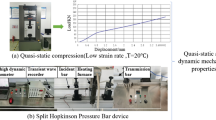

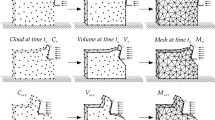

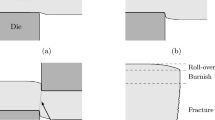

This contribution presents the model of a ‘granular solid’ based on the Discrete Element Method which is used to model cutting processes of cohesive and ductile materials, e.g. aluminum. The model is based on a conventional three-dimensional Discrete Element approach which employs rigid spheres as it is used to model granular media. Including cohesive interactions besides the repulsive interactions of the basic model allows for the particle agglomerate to display cohesive and ductile behavior. Using the thus generated granular solid the failure modes of ductile engineering materials like aluminum can be qualitatively and quantitatively reproduced. This is shown by comparison with experiments of a tensile and a Charpy impact test. To show the applicability of the approach for manufacturing problems an orthogonal cutting process of steel and aluminum is modelled and the cutting forces are compared to experiments. To further enhance the model thermal interactions between particles are included. The thermodynamics during cutting due to dissipative phenomena is evaluated and compared to experiments.

Similar content being viewed by others

References

Cundall PA (2009) A computer model for simulating progressive, large-scale movements in blocky rock systems. In: Proceedings of the Symposium of the International Society of Rock Mechanics, vol 1:II-8

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotechnique 1: 47–65

Fleissner F (2010) Parallel object oriented simulation with Lagrangian particle methods. Doctoral thesis, Institute of Engineering and Computational Mechanics, University of Stuttgart, Shaker, Aachen

Williams J, Perkins E, Cook B (2004) A contact algorithm for partitioning n arbitrary sized objects. Eng Comp 21: 235–248

Jing L, Stephansson O (2007) Fundamentals of discrete element methods for rock engineering: theory and applications, vol 85 of developments in geotechnical engineering. Elsevier, Amsterdam

Luding S (1998) Die Physik kohäsionsloser granularer Medien (in German). Logos, Berlin

Cundall P, Hart R (1992) Numerical modelling of discontinua. Eng Comp 9: 101–113

Lankarani HM, Nikravesh PE (1990) A contact force model with hysteresis damping for impact analysis of multibody systems. J Mech Des 112: 369–376

Kuwabara G, Kono K (1987) Restitution coefficient in a collision between two spheres. Jpn J Appl Phys 26: 1230–1233

Schäer J, Dippel S, Wolf DE (1996) Force schemes in simulations of granular materials. J Phys I France 6: 5–20

Fleissner F, Gaugele T, Eberhard P (2007) Applications of the discrete element method in mechanical engineering. Multibody Syst Dyn 18: 81–94

D’Addetta GA, Ramm E (2006) A microstructure-based simulation environment on the basis of an interface enhanced particle model. Granul Matter 8: 159–174

Liu K, Gao L, Tanimura S (2004) Application of discrete element method in impact problems. JSME Int J Ser A 47: 138–145

Bagi K (2005) An algorithm to generate random dense arrangements for discrete element simulations of granular assemblies. Granul Matter 7: 31–43

Jerier JF, Imbault D, Donze FV, Doremus P (2009) A geometric algorithm based on tetrahedral meshes to generate a dense polydisperse sphere packing. Granul Matter 11: 43–52

Cui L, O’Sullivan C (2003) Analysis of a triangulation based approach for specimen generation for discrete element simulations. Granul Matter 5: 135–145

Gaugele T, Fleissner F, Eberhard P (2008) Simulation of material tests using meshfree Lagrangian particle methods. Proc Inst Mech Eng Part K J Multi-body Dyn 222: 327–338

Ergenzinger C, Seifried R, Eberhard P (2010) A discrete element model to describe failure of strong rock in uniaxial compression. Granul Matter. doi:10.1007/s10035-010-0230-7

Gaugele T (2011) Application of the discrete element method to model ductile, heat conductive materials. Doctoral thesis, Institute of Engineering and Computational Mechanics, University of Stuttgart, Shaker, Aachen

NN (2001) Metallische Werkstoffe Zugversuch—Prüfverfahren bei Raumtemperatur (in German). DIN Deutsches Institut für Normung e.V., Berlin

NN (1991) Kerbschlagbiegeversuch nach Charpy (in German). DIN Deutsches Institut für Normung e.V., Berlin

Holman J (1997) Heat transfer. McGraw-Hill, New York

Munz CD, Westermann T (2006) Numerische Behandlung gewönlicher und partieller Differentialgleichungen (in German). Springer, Berlin

Bronstein IN, Semendjajew KA, Musiol G, Mühlig H (2001) Taschenbuch der Mathematik (in German). Verlag Harri Deutsch, Frankfurt am Main

Polifke W, Kopitz J (2005) Wärmeübertragung—Grundlagen, analytische und numerische Methoden (in German). Pearson, München

Jaspers SP (1999) Metal cutting mechanics and material behaviour. Dissertation, Universiteit Eindhoven

Farren W, Taylor G (1925) The heat developed during plastic extension of metals. Proc R Soc Ser A 107: 422–451

Taylor G, Quinney M (1934) The latent heat remaining in a metal after cold work. Proc R Soc Ser A 143: 307–326

Hodowany J, Ravichandran G, Rosakis A, Rosakis P (2000) Partition of plastic work into heat and stored energy in metals. Exp Mech 40: 113–123

Hodowany J (1997) On the conversion of plastic work into heat. Dissertation, California Institute of Technology

Zehnder A, Potdar Y, Bhalla K (2002) Plasticity induced heating in the fracture and cutting of metals. In: Aliabadi MH (ed) Thermo mechanical fatigue and fracture. WIT Press, Southampton, pp 209–244

Jaspers S, Dautzenberg J (2002) Material behaviour in metal cutting: strains, strain rates, and temperatures in metal cutting. J Mater Process Technol 121: 123–135

Vormann K, Frank P, Witt S, Schermann T (2007) Abschlussbericht des Verbundforschungsprojekts Sindbap—simulation industrieller Bearbeitungsprozesse (in German). Tech. rep., Forschungszentrum Karlsruhe

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Eberhard, P., Gaugele, T. Simulation of cutting processes using mesh-free Lagrangian particle methods. Comput Mech 51, 261–278 (2013). https://doi.org/10.1007/s00466-012-0720-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-012-0720-z