Abstract

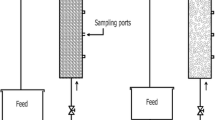

Plate and frame filter used as a recirculated batch reactor for the production of 6-APA was studied. Penicillin-G solution was recirculated between the immobilized penicillin-G amidase (IPGA) loaded filter and the pH controlled neutralization tank. As penicillin-G solution flowed convectively through the frames loaded with IPGA particles, penicillin-G was hydrolyzed by IPGA and 6-APA was produced. Because of the large filtration area and short filtration depth of plate and frame filter, the batch hydrolysis reaction was operated at high recirculation flow rate without causing high pressure drop. The effect of recirculation flow rate on 2% penicillin-G hydrolysis was stronger than that on 8% penicillin-G hydrolysis. The amount of IPGA loaded in filter had no significant effect on the production yield of IPGA. The operational stability of IPGA in the filter was very satisfactory. There was no appreciable activity decrease after 25 batches of reaction.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 22 April 1996

Rights and permissions

About this article

Cite this article

Lee, CK., Chang, SK. Plate and frame filter as a recirculated batch reactor for penicillin-G amidase. Bioprocess Engineering 16, 87–91 (1997). https://doi.org/10.1007/s004490050293

Issue Date:

DOI: https://doi.org/10.1007/s004490050293