Abstract

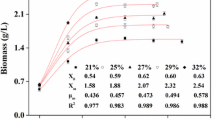

In this study, the synthesis of xylonic acid from xylose by Gluconobacter oxydans NL71 has been investigated. According to the relationship between oxygen transfer rate and oxygen uptake rate, three different kinetic models of product formation were established and the nonlinear fitting was carried out. The results showed that G. oxydans has critical dissolved oxygen under different strain concentrations, and the relationship between respiration intensity and dissolved oxygen conformed to the Monod equation \(q_{{{\text{O}}_{2} }} = q_{{{\text{O}}_{2} ,\max }} \frac{{C_{{\text{L}}} }}{{K_{{{\text{O}}_{2} }} + C_{{\text{L}}} }}\). The maximum reaction rate per unit cell mass and the theoretical maximum specific productivity of G. oxydans obtained by the kinetic model are 0.042 mol/L/h and 6.97 g/gx/h, respectively. These results will assist in determining the best balance between the airflow rate and cell concentration in the reaction and improve the production efficiency of xylonic acid.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author, Xu, upon reasonable request.

References

Isikgor FH, Becer CR (2015) Lignocellulosic biomass: a sustainable platform for the production of bio-based chemicals and polymers. Polym Chem 6:4497–4559

Wu JQ, Hu JL, Zhao SM, He MX, Hu GQ, Ge XY, Peng N (2018) Single-cell Protein and Xylitol Production by a Novel Yeast Strain Candida intermedia FL023 from Lignocellulosic Hydrolysates and Xylose. Appl Biochem Biotechnol 185:163–178

Hou WL, Bao J (2019) Evaluation of cement retarding performance of cellulosic sugar acids. Constr Build Mater 202:522–527

Zhou X, Zhou XL, Tang XS, Xu Y (2018) Process for calcium xylonate production as a concrete admixture derived from in-situ fermentation of wheat straw pre-hydrolysate. Biores Technol 261:288–293

Gao Q, Wang X, Hu SW, Xu NN, Jiang MJ, Ma C, Yang JM, Xu S, Chen KQ, Ouyang PK (2019) High-yield production of D-1,2,4-butanetriol from lignocellulose-derived xylose by using a synthetic enzyme cascade in a cell-free system. J Biotechnol 292:76–83

Hahn T, Torkler S, van Der Bolt R, Gammel N, Hesse M, Moller A, Preylowski B, Hubracht V, Patzsch K, Zibek S (2020) Determining different impact factors on the xylonic acid production using Gluconobacter oxydans DSM 2343. Process Biochem 94:172–179

Jin C, Hou W, Yao R, Zhou P, Zhang H, Bao J (2019) Adaptive evolution of Gluconobacter oxydans accelerates the conversion rate of non-glucose sugars derived from lignocellulose biomass. Biores Technol 289:121623

Hua X, Zhou X, Du G, Xu Y (2020) Resolving the formidable barrier of oxygen transferring rate (OTR) in ultrahigh-titer bioconversion/biocatalysis by a sealed-oxygen supply biotechnology (SOS). Biotechnol Biofuels 13:1–12

Han J, Hua X, Zhou X, Xu B, Wang H, Huang G, Xu Y (2021) A cost-practical cell-recycling process for xylonic acid bioproduction from acidic lignocellulosic hydrolysate with whole-cell catalysis of Gluconobacter oxydans. Biores Technol 333:125157

Keliang G, Dongzhi W (2006) Asymmetric oxidation by Gluconobacter oxydans. Appl Microbiol Biotechnol 70:135–139

Deppenmeier U, Hoffmeister M, Prust C (2002) Biochemistry and biotechnological applications of Gluconobacter strains. Appl Microbiol Biotechnol 60:233–242

Rocha-Martin J, Acosta A, Berenguer J, Guisan JM, Lopez-Gallego F (2014) Selective oxidation of glycerol to 1, 3-dihydroxyacetone by covalently immobilized glycerol dehydrogenases with higher stability and lower product inhibition. Biores Technol 170:445–453

Xu MQ, Li FL, Yu WQ, Li RF, Zhang YW (2020) Combined cross-linked enzyme aggregates of glycerol dehydrogenase and NADH oxidase for high efficiency in situ NAD+ regeneration. Int J Biol Macromol 144:1013–1021

Zhou X, Zhou X, Xu Y (2017) Improvement of fermentation performance of Gluconobacter oxydans by combination of enhanced oxygen mass transfer in compressed-oxygen-supplied sealed system and cell-recycle technique. Biores Technol 244:1137–1141

Hua X, Han J, Zhou X, Xu Y (2022) Gas pressure intensifying oxygen transfer to significantly improving the bio‐oxidation productivity of whole‐cell catalysis. AIChE Journal, e18005.

Hou W, Li L, Bao J (2017) Oxygen transfer in high solids loading and highly viscous lignocellulose hydrolysates. ACS Sustainable Chemistry & Engineering 5:11395–11402

Ripoll V, Ladero M, Santos VE (2021) Kinetic modelling of 2, 3-butanediol production by Raoultella terrigena CECT 4519 resting cells: Effect of fluid dynamics conditions and initial glycerol concentration. Biochem Eng J 176:108185

Zhang Y, Zhang Y, Song MJ, Topakas E, Yu Q, Yuan ZH, Wang ZM, Guo Y (2021) Combining Michaelis-Menten theory and enzyme deactivation reactions for the kinetic study of enzymatic hydrolysis by different pretreated sugarcane bagasse. Process Biochem 105:72–78

de la Morena S, Wojtusik M, Santos VE, Garcia-Ochoa F (2020) Kinetic modeling of dihydroxyacetone production from glycerol by Gluconobacter oxydans ATCC 621 resting cells: Effect of fluid dynamics conditions. Catalysts 10:101

Dikshit PK, Moholkar VS (2016) Kinetic analysis of dihydroxyacetone production from crude glycerol by immobilized cells of Gluconobacter oxydans MTCC 904. Biores Technol 216:948–957

Zhang Z, Zhu X, Xie P, Sun J, Yuan J (2012) Macrokinetic model for Gluconobacter oxydans in 2-keto-L-gulonic acid mixed culture. Biotechnol Bioprocess Eng 17:1008–1017

Xu C, He T, Zhou X, Xu Y, Gu X (2021) Influence of oxygen transfer and uptake rates on xylonic acid production from xylose by Gluconobacter oxydans. Biochem Eng J 176:108192

Zhou XL, Zhou X, Liu G, Xu Y, Balan V (2018) Integrated production of gluconic acid and xylonic acid using dilute acid pretreated corn stover by two-stage fermentation. Biochem Eng J 137:18–22

Dai L, Jiang WF, Zhou X, Xu Y (2020) Enhancement in xylonate production from hemicellulose pre-hydrolysate by powdered activated carbon treatment. Bioresource Technology 316.

Wang X, Xu Y, Lian ZN, Yong Q, Yu SY (2014) A One-Step Method for the Simultaneous Determination of Five Wood Monosaccharides and the Corresponding Aldonic Acids in Fermentation Broth Using High-Performance Anion-Exchange Chromatography Coupled with a Pulsed Amperometric Detector. J Wood Chem Technol 34:67–76

Garcia-Ochoa F, Gomez E (2009) Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview. Biotechnol Adv 27:153–176

Gomez E, Santos V, Alcon A, Garcia-Ochoa F (2006) Oxygen transport rate on Rhodococcus erythropolis cultures: Effect on growth and BDS capability. Chem Eng Sci 61:4595–4604

Acknowledgements

This work was funded by the National Natural Science Foundation of China (No. 22208160), the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (No. 21KJB530015) and the National key research and development program (2021YFC2101602).

Author information

Authors and Affiliations

Contributions

XL: investigation, data curation, writing—original draft. CD: investigation, data curation, writing—original draft. TH: validation, investigation, data curation. YZ: formal analysis. LS: formal analysis. CX: conceptualization, methodology, software, writing—review and editing, visualization, supervision, project administration, funding acquisition. XG: resources, supervision, project administration.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, X., Ding, C., He, T. et al. Kinetic modeling of xylonic acid production by Gluconobacter oxydans: effects of hydrodynamic conditions. Bioprocess Biosyst Eng 46, 829–837 (2023). https://doi.org/10.1007/s00449-023-02865-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-023-02865-6