Abstract

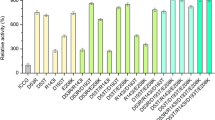

Polyethylene terephthalate (PET) waste has caused serious environmental pollution. Recently, PET depolymerization by enzymes with PET-depolymerizing activity has received attention as a solution to recycle PET. An engineered variant of leaf-branch compost cutinase (293 amino acid), ICCG (Phe243Ile/Asp238Cys/Ser283Cys/Tyr127Gly), showed excellent depolymerizing activity toward PET at 72 °C, which was the highest depolymerizing activity and thermo-stability ever reported in previous works. However, this enzyme was only produced by heterologous expression in the cytoplasm of Escherichia coli, which requires complex separation and purification steps. To simplify the purification steps of ICCG, we developed a secretory production system using Bacillus subtilis and its 174 types of N-terminal signal peptides. The recombinant strain expressing ICCG with the signal peptide of serine protease secreted the highest amount (9.4 U/mL) of ICCG. We improved the production of ICCG up to 22.6 U/mL (85 μg/mL) by performing batch fermentation of the selected strain in 2 L working volume using a 5-L fermenter, and prepared the crude ICCG solution by concentrating the culture supernatant. The recombinant ICCG successfully depolymerized a PET film with 37% crystallinity at 37 °C and 70 °C. In this study, we developed a secretory production system of the engineered cutinase with PET-depolymerizing activity to obtain high amounts of the enzyme by a relatively simple purification method. This system will contribute to the recycling of PET waste via a more efficient and environmentally friendly method based on enzymes with PET-depolymerizing activity.

Similar content being viewed by others

References

Chen CC, Han X, Ko TP, Liu W, Guo RT (2018) Structural studies reveal the molecular mechanism of PETase. FEBS J 285:3717–3723. https://doi.org/10.1111/febs.14612

Sinha V, Patel MR, Patel JV (2010) Pet waste management by chemical recycling: a review. J Polym Environ 18:8–25. https://doi.org/10.1007/s10924-008-0106-7

Andrady AL, Neal MA (2009) Applications and societal benefits of plastics. Philosophical transactions of the Royal Society of London. Series B Biolog Sci 364:1977–1984. https://doi.org/10.1098/rstb.2008.0304

Park SH, Kim SH (2014) Poly (ethylene terephthalate) recycling for high value added textiles. Fash Textil 1:1. https://doi.org/10.1186/s40691-014-0001-x

Kim JW, Park S-B, Tran Q-G, Cho D-H, Choi D-Y, Lee YJ, Kim H-S (2020) Functional expression of polyethylene terephthalate-degrading enzyme (PETase) in green microalgae. Microb Cell Fact 19:97. https://doi.org/10.1186/s12934-020-01355-8

Taniguchi I, Yoshida S, Hiraga K, Miyamoto K, Kimura Y, Oda K (2019) Biodegradation of PET: current status and application aspects. ACS Catal 9:4089–4105. https://doi.org/10.1021/acscatal.8b05171

Maurya A, Bhattacharya A, Khare SK (2020) Enzymatic remediation of polyethylene terephthalate (PET)–based polymers for effective management of plastic wastes: an overview. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2020.602325

Tournier V, Topham CM, Gilles A, David B, Folgoas C, Moya-Leclair E, Kamionka E, Desrousseaux ML, Texier H, Gavalda S, Cot M, Guémard E, Dalibey M, Nomme J, Cioci G, Barbe S, Chateau M, André I, Duquesne S, Marty A (2020) An engineered PET depolymerase to break down and recycle plastic bottles. Nature 580:216–219. https://doi.org/10.1038/s41586-020-2149-4

Ragaert K, Delva L, Van Geem K (2017) Mechanical and chemical recycling of solid plastic waste. Waste Manag 69:24–58. https://doi.org/10.1016/j.wasman.2017.07.044

Ma Y, Yao M, Li B, Ding M, He B, Chen S, Zhou X, Yuan Y (2018) Enhanced poly(ethylene terephthalate) hydrolase activity by protein engineering. Engineering 4:888–893. https://doi.org/10.1016/j.eng.2018.09.007

Wei R, Zimmermann W (2017) Biocatalysis as a green route for recycling the recalcitrant plastic polyethylene terephthalate. Microb Biotechnol 10:1302–1307. https://doi.org/10.1111/1751-7915.12714

Carr CM, Clarke DJ, Dobson ADW (2020) Microbial polyethylene terephthalate hydrolases: current and future perspectives. Front Microbiol 11:571265. https://doi.org/10.3389/fmicb.2020.571265

Son HF, Cho IJ, Joo S, Seo H, Sagong H-Y, Choi SY, Lee SY, Kim K-J (2019) Rational protein engineering of thermo-stable PETase from Ideonella sakaiensis for highly efficient PET degradation. ACS Catal 9:3519–3526. https://doi.org/10.1021/acscatal.9b00568

Eom GT, Song JK, Ahn JH, Seo YS, Rhee JS (2005) Enhancement of the efficiency of secretion of heterologous lipase in Escherichia coli by directed evolution of the ABC transporter system. Appl Environ Microbiol 71:3468–3474. https://doi.org/10.1128/AEM.71.7.3468-3474.2005

Makrides SC (1996) Strategies for achieving high-level expression of genes in Escherichia coli. Microbiol Rev 60:512–538. https://doi.org/10.1128/mr.60.3.512-538.1996

Ward OP (2012) Production of recombinant proteins by filamentous fungi. Biotechnol Adv 30:1119–1139. https://doi.org/10.1016/j.biotechadv.2011.09.012

Eom GT, Lee SH, Song BK, Chung KW, Kim YW, Song JK (2013) High-level extracellular production and characterization of Candida antarctica lipase B in Pichia pastoris. J Biosci Bioeng 116:165–170. https://doi.org/10.1016/j.jbiosc.2013.02.016

Burdette LA, Leach SA, Wong HT, Tullman-Ercek D (2018) Developing Gram-negative bacteria for the secretion of heterologous proteins. Microb Cell Fact 17:196. https://doi.org/10.1186/s12934-018-1041-5

Yao D, Su L, Li N, Wu J (2019) Enhanced extracellular expression of Bacillus stearothermophilus α-amylase in Bacillus subtilis through signal peptide optimization, chaperone overexpression and α-amylase mutant selection. Microb Cell Fact 18:69. https://doi.org/10.1186/s12934-019-1119-8

Ma J, Zhang Z, Wang B, Kong X, Wang Y, Cao S, Feng Y (2006) Overexpression and characterization of a lipase from Bacillus subtilis. Protein Expr Purif 45:22–29. https://doi.org/10.1016/j.pep.2005.06.004

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685. https://doi.org/10.1038/227680a0

Xu H, Yan Q, Duan X, Yang S, Jiang Z (2015) Characterization of an acidic cold-adapted cutinase from Thielavia terrestris and its application in flavor ester synthesis. Food Chem 188:439–445. https://doi.org/10.1016/j.foodchem.2015.05.026

Zhang K, Su L, Duan X, Liu L, Wu J (2017) High-level extracellular protein production in Bacillus subtilis using an optimized dual-promoter expression system. Microb Cell Fact 16:32. https://doi.org/10.1186/s12934-017-0649-1

Zhang K, Su L, Wu J (2020) Recent advances in recombinant protein production by Bacillus subtilis. Annu Rev Food Sci Technol 11:295–318. https://doi.org/10.1146/annurev-food-032519-051750

Cai D, Rao Y, Zhan Y, Wang Q, Chen S (2019) Engineering Bacillus for efficient production of heterologous protein: current progress, challenge and prospect. J Appl Microbiol 126:1632–1642. https://doi.org/10.1111/jam.14192

Vuolanto A, von Weymarn N, Kerovuo J, Ojamo H, Leisola M (2001) Phytase production by high cell density culture of recombinant Bacillus subtilis. Biotech Lett 23:761–766. https://doi.org/10.1023/A:1010369325558

Xi X, Ni K, Hao H, Shang Y, Zhao B, Qian Z (2021) Secretory expression in Bacillus subtilis and biochemical characterization of a highly thermostable polyethylene terephthalate hydrolase from bacterium HR29. Enzyme Microb Technol 143:109715. https://doi.org/10.1016/j.enzmictec.2020.109715

Kim HT, Kim JK, Cha HG, Kang MJ, Lee HS, Khang TU, Yun EJ, Lee D-H, Song BK, Park SJ, Joo JC, Kim KH (2019) Biological valorization of poly(ethylene terephthalate) monomers for upcycling waste PET. ACS Sustain Chem Eng 7:19396–19406. https://doi.org/10.1021/acssuschemeng.9b03908

Awaja F, Pavel D (2005) Recycling of PET. Eur Polymer J 41:1453–1477. https://doi.org/10.1016/j.eurpolymj.2005.02.005

Raheem AB, Noor ZZ, Hassan A, Abd Hamid MK, Samsudin SA, Sabeen AH (2019) Current developments in chemical recycling of post-consumer polyethylene terephthalate wastes for new materials production: A review. J Clean Prod 225:1052–1064. https://doi.org/10.1016/j.jclepro.2019.04.019

George N, Kurian T (2014) Recent developments in the chemical recycling of postconsumer poly(ethylene terephthalate) waste. Ind Eng Chem Res 53:14185–14198. https://doi.org/10.1021/ie501995m

Kenny ST, Runic JN, Kaminsky W, Woods T, Babu RP, Keely CM, Blau W, O’Connor KE (2008) Up-cycling of PET (Polyethylene Terephthalate) to the biodegradable plastic PHA (Polyhydroxyalkanoate). Environ Sci Technol 42:7696–7701. https://doi.org/10.1021/es801010e

Kenny ST, Runic JN, Kaminsky W, Woods T, Babu RP, O’Connor KE (2012) Development of a bioprocess to convert PET derived terephthalic acid and biodiesel derived glycerol to medium chain length polyhydroxyalkanoate. Appl Microbiol Biotechnol 95:623–633. https://doi.org/10.1007/s00253-012-4058-4

Acknowledgements

This work was supported by the R&D program of MOTIE/KEIT [10077291]; the R&D programs of KRICT [SS2142-10, BSF21-505]; and the R&D program of Ulsan-KRICT [US21-12, US21-12-01].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Oh, YR., Jang, YA., Song, J.K. et al. Secretory production of an engineered cutinase in Bacillus subtilis for efficient biocatalytic depolymerization of polyethylene terephthalate. Bioprocess Biosyst Eng 45, 711–720 (2022). https://doi.org/10.1007/s00449-022-02690-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-022-02690-3