Abstract

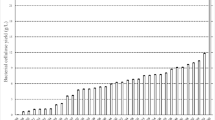

Bacterial cellulose (BC) exhibits a unique combination of porosity, tensile strength, reticulated crystal structure and biocompatibility useful for many applications in the food, biomedical and other industries. Polysaccharide addition has been shown to improve the production and the mechanical properties of BC nanocomposites. This study examined the effect of pullulan on BC fermentation as well as the co-culturing of the BC producer with Aureobasidium pullulans, a fungal strain that produces pullulan as an exopolysaccharide. Results showed that a 1% pullulan addition improved Young’s modulus of BC pellicles for sixfold. Addition of pullulan at 1.5% and 2% levels could increase the BC production from 0.447 to 0.814 and 1.997 g/L, respectively. The co-culture fermentation demonstrated a mixed effect on the aggregation and bundling of BC while resulting in a significant improvement in mechanical properties. The study provided a polysaccharide additive and a novel fermentation method to produce BC with improved properties.

Similar content being viewed by others

Availability of data and material

All data generated or analyzed during this study are included in this published article [and its supplementary information files].

Code availability

Not applicable.

References

Atalla R, Hackney J, Uhlin I, Thompson N (1993) Hemicelluloses as structure regulators in the aggregation of native cellulose. Int J Biol Macromol 15(2):109–112

Backdahl H, Helenius G, Bodin A, Nannmark U, Johansson BR, Risberg B, Gatenholm P (2006) Mechanical properties of bacterial cellulose and interactions with smooth muscle cells. Biomaterials 27(9):2141–2149

Benziman M, Haigler CH, Brown RM, White R, Cooper KM (1980) Cellulose biogenesis: polymerization and crystallization are coupled processes in Acetobacter xylinum. Proc Natl Acad Sci USA 77(11):6678–6682

Bootten TJ, Harris PJ, Melton LD, Newman RH (2008) WAXS and 13C NMR study of Gluconoacetobacter xylinus cellulose in composites with tamarind xyloglucan. Carbohyd Res 343(2):221–229

Cacicedo ML, León IE, Gonzalez JS, Porto LM, Alvarez VA, Castro GR (2016) Modified bacterial cellulose scaffolds for localized doxorubicin release in human colorectal HT-29 cells. Colloids Surf, B 140:421–429

Chao Y, Mitarai M, Sugano Y, Shoda M (2001) Effect of addition of water-soluble polysaccharides on bacterial cellulose production in a 50-L airlift reactor. Biotechnol Prog 17(4):781–785

Cheng KC (2010) Enhanced production of microbial extracellular polysaccharides and materials property analysis (unpublished doctoral dissertation). The Pennsylvania State University, University Park, PA

Cheng KC, Catchmark JM, Demirci A (2009) Enhanced production of bacterial cellulose by using a biofilm reactor and its material property analysis. J Biol Eng 3(1):12

Cheng KC, Demirci A, Catchmark JM (2009) Effects of plastic composite support and pH profiles on pullulan production in a biofilm reactor. Appl Microbiol Biotechnol 86(3):853–861

Cheng KC, Catchmark JM, Demirci A (2011) Effects of CMC addition on bacterial cellulose production in a biofilm reactor and its paper sheets analysis. Biomacromol 12(3):730–736

Cheng K, Demirci A, Catchmark JM (2011) Continuous pullulan fermentation in a biofilm reactor. Appl Microbiol Biotechnol 90(3):921–927

Chi K, Catchmark JM (2017) The influences of added polysaccharides on the properties of bacterial crystalline nanocellulose. Nanoscale 9(39):15144–15158

Czaja W, Romanovicz D, Brown RM (2004) Structural investigations of microbial cellulose produced in stationary and agitated culture. Cellulose 11(3/4):403–411

Dayal MS, Catchmark JM (2016) Mechanical and structural property analysis of bacterial cellulose composites. Carbohyd Polym 144:447–453

Fang L, Catchmark JM (2014) Characterization of water-soluble exopolysaccharides from Gluconacetobacter xylinus and their impacts on bacterial cellulose crystallization and ribbon assembly. Cellulose 21:3965–3978

Fang L, Catchmark JM (2015) Characterization of cellulose and other exopolysaccharides produced from Gluconacetobacter strains. Carbohyd Polym 115:663–669

Gromovykh TI, Gavryushina IA, Sadykova VS, Feldman NB, Dmitrenok AS, Ayrapetova AY, Lutsenko SV (2018) Obtaining immobilized mycelium of basidiomycete Fomitopsis officinalis (Vill.:Fr.) Bond. Et Sing., producer of agaricic acid. Antibiot Chemother 63(9–10):3–9 (In Russian)

Gu J, Catchmark JM (2013) The impact of cellulose structure on binding interactions with hemicellulose and pectin. Cellulose 20(4):1613–1627

Haigler CH, Brown R, Benziman M (1980) Calcofluor white ST Alters the in vivo assembly of cellulose microfibrils. Science 210(4472):903–906

Haigler CH, White AR, Brown RM, Cooper KM (1982) Alteration of in vivo cellulose ribbon assembly by carboxymethylcellulose and other cellulose derivatives. J Cell Biol 94(1):64–69

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum. 2. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58(2):345–352

Hickey RJ, Pelling AE (2019) Cellulose biomaterials for tissue engineering. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2019.00045

Hirai A, Tsuji M, Yamamoto H, Horii F (1998) In situ crystallization of bacterial cellulose III. Influences of different polymeric additives on the formation of microfibrils as revealed by transmission electron microscopy. Cellulose 5:201–213

Hsieh YC, Yano H, Nogi M, Eichhorn SJ (2008) An estimation of the Young’s modulus of bacterial cellulose filaments. Cellulose 15(4):507–513

Hu H, Catchmark JM, Demirci A (2021) Co-culture fermentation on the production of bacterial cellulose nanocomposite produced by komagataeibacter hansenii. Carbohyd Polym Technol Appl 2:100028

Ishida T, Mitarai M, Sugano Y, Shoda M (2003) Role of water-soluble polysaccharides in bacterial cellulose production. Biotechnol Bioeng 83(4):474–478

Jarvis MC (2000) Interconversion of the Iα and Iβ crystalline forms of cellulose by bending. Carbohyd Res 325(2):150–154

Klemm D, Ahrem H, Kramer F, Fried W, Wippermann J, Kinne RW (2016) Bacterial nanocellulose hydrogels designed as bioartificial medical implants. Bact NanoCell Sophistic Multifunct Mat 1:176–198

Liu K, Catchmark JM (2018) Effects of exopolysaccharides from Escherichia coli ATCC 35860 on the mechanical properties of bacterial cellulose nanocomposites. Cellulose 25(4):2273–2287

Liu K, Catchmark JM (2019) Enhanced mechanical properties of bacterial cellulose nanocomposites produced by co-culturing Gluconacetobacter hansenii and Escherichia coli under static conditions. Carbohyd Polym 219:12–20

Liu K, Catchmark JM (2020) Bacterial cellulose/hyaluronic acid nanocomposites production through co-culturing Gluconacetobacter hansenii and Lactococcus lactis under different initial pH values of fermentation media. Cellulose 27:2529–2540

Meza-Contreras JC, Manriquez-Gonzalez R, Gutiérrez-Ortega JA, Gonzalez-Garcia Y (2018) XRD and solid state 13C-NMR evaluation of the crystallinity enhancement of 13C-labeled bacterial cellulose biosynthesized by Komagataeibacter xylinus under different stimuli: a comparative strategy of analyses. Carbohyd Res 461:51–59

Müller D, Rambo CR, Porto LM, Schreiner WH, Barra GMO (2013) Structure and properties of polypyrrole/bacterial cellulose nanocomposites. Carbohyd Polym 94(1):655–662

Nakagaito A, Iwamoto S, Yano H (2005) Bacterial cellulose: the ultimate nano-scalar cellulose morphology for the production of high-strength composites. J Appl Phys 80:93–97

Nieduszynski I, Preston RD (1970) Crystallite size in natural cellulose. Nature 225(5229):273–274

Okiyama A, Motoki M, Yamanaka S (1992) Bacterial cellulose II. Processing of the gelatinous cellulose for food materials. Food Hydrocoll 6(5):479–487

Okiyama A, Motoki M, Yamanaka S (1993) Bacterial cellulose IV. Application to processed foods. Food Hydrocoll 6(6):503–511

Parte FGB, Santoso SP, Chou CC, Verma V, Wang H-T, Ismadji S, Cheng KC (2020) Current progress on the production, modification, and applications of bacterial cellulose. Crit Rev Biotechnol 40(3):397–414

Pollock TJ, Thorne L, Armentrout RW (1992) Isolation of new Aureobasidium strains that produce high-molecular-weight pullulan with reduced pigmentation. Appl Environ Microbiol 58(3):877–883

Reiniati I, Hrymak AN, Margaritis A (2017) Recent developments in the production and applications of bacterial cellulose fibers and nanocrystals. Crit Rev Biotechnol 37(4):1–15

Ronen M, Guterman H, Shabtai Y (2002) Monitoring and control of pullulan production using vision sensor. J Biochem Biophys Methods 51(3):243–249

Ross P, Mayer R, Benziman M (1991) Cellulose biosynthesis and function in bacteria. Microbiol Rev 55(1):35–58

Santoso SP, Chou CC, Lin SP, Soetaredjo FE, Ismadji S, Hsieh CW, Cheng KC (2020) Enhanced production of bacterial cellulose by Komactobacter intermedius using statistical modeling. Cellulose 27(5):2497–2509

Santoso SP, Lin SP, Wang TY, Ting Y, Hsieh CW, Yu RC, Angkawijaya AE, Soetaredjo FE, Hsu HY, Cheng KC (2021) Atmospheric cold plasma-assisted pineapple peel waste hydrolysate detoxification for the production of bacterial cellulose. Int J Biol Macromol 175:526–534

Schlueter K, Johnson J, Warner C, Miller W (2017) Glucose analytical comparability evaluation of the YSI 2300 STAT Plus™ and YSI 2900D biochemistry analyzers. YSI Life Sciences White Paper B91. Retrieved from https://www.ysi.com/File%20Library/Documents/White%20Papers/Glucose-Analytical-Comparability-White-Paper-B91.pdf. Accessed 4 Dec 2021

Seo HP, Chung HC, Sung KK, Richard AG, David LK, Jin WL (2004) Mass production of pullulan with optimized concentrations of carbon and nitrogen sources by Aureobasidium pullulans HP-2001 in a 100-L bioreactor with the inner pressure. J Microbiol Biotechnol 14(2):237–242

Shoda M, Sugano Y (2005) Recent advances in bacterial cellulose production. Biotechnol Bioprocess Eng 10(1):1–8

Shokatayeva D, Ignatova L, Savitskaya I, Kistaubaeva A, Talipova A, Asylbekova A, Mashzhan A (2019) Bacterial cellulose and pullulan from simple and low cost production media. Eurasian Chem Technol J 21(3):247–258

Son HJ, Heo MS, Kim YG, Lee SJ (2001) Optimization of fermentation conditions for the production of bacterial cellulose by a newly isolated Acetobacter sp. A9 in shaking cultures. Biotechnol Appl Biochem 33(1):1–5

Tajima K, Uenishi N, Fujiwara M, Erata T, Munekata M, Takai M (1997) The production of a new water-soluble polysaccharide by Acetobacter xylinum NCI 1005 and its structural analysis by NMR spectroscopy. Carbohyd Res 305(1):117–122

Tiwari S, Patil R, Dubey SK, Bahadur P (2019) Derivatization approaches and applications of pullulan. Adv Coll Interface Sci 269:296–308

Tokoh C, Takabe K, Fujita M et al (1998) Cellulose synthesized by Acetobacter Xylinum in the presence of acetyl glucomannan. Cellulose 5:249–261

Trovatti E, Fernandes SC, Rubatat L, Freire CS, Silvestre AJ, Neto CP (2012) Sustainable nanocomposite films based on bacterial cellulose and pullulan. Cellulose 19(3):729–737

Tsouko E, Kourmentza C, Ladakis D, Kopsahelis N, Mandala I, Papanikolaou S, Paloukis F, Alves V, Koutinas A (2015) Bacterial cellulose production from industrial waste and by-product streams. Int J Mol Sci 16(12):14832–14849

Uhlin KI, Atalla RH, Thompson NS (1995) Influence of hemicelluloses on the aggregation patterns of bacterial cellulose. Cellulose 2(2):129–144

Weng Y, Nagle B, Mueller K, Catchmark JM (2019) The formation of Gluconacetobacter xylinum cellulose under the influence of the dye brilliant yellow. Cellulose 26:9373–9386

West TP, Reed-Hamer B (1993) Polysaccharide production by a reduced pigmentation mutant of the fungus Aureobasidium pullulans. FEMS Microbiol Lett 113(3):345–349

Xiao Q, Tong Q, Zhou Y, Deng F (2015) Rheological properties of pullulan-sodium alginate-based solutions during film formation. Carbohyd Polym 130:49–56

Yamamoto H, Horii F, Hirai A (1996) In situ crystallization of bacterial cellulose II. Influences of different polymeric additives on the formation of celluloses Iα and Iβ at the early stage of incubation. Cellulose 3(1):229–242

Yuen S (1974) Pullulan and its applications. Process Biochem 9(9):7–9

Acknowledgements

This work was supported by the USDA National Institute of Food and Agriculture Federal Appropriations under Project PAES 4602, accession number 1009850. The study is also supported in-part by Penn State Center of Excellence in Industrial Biotechnology Seed Grant.

Author information

Authors and Affiliations

Contributions

Conceptualization: JMC, AD; methodology: HH, JMC, AD; formal analysis and investigation: HH, JMC, AD; writing—original draft preparation: HH; writing—review and editing: JMC, AD; funding acquisition: JMC, AD; resources: JMC, AD; supervision: JMC.

Corresponding author

Ethics declarations

Conflict of interest

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hu, H., Catchmark, J.M. & Demirci, A. Effects of pullulan additive and co-culture of Aureobasidium pullulans on bacterial cellulose produced by Komagataeibacter hansenii. Bioprocess Biosyst Eng 45, 573–587 (2022). https://doi.org/10.1007/s00449-021-02680-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-021-02680-x