Abstract

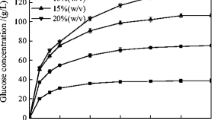

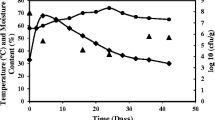

Agricultural wastes rich in lignocellulosic biomass have been used in the production of poly-γ-glutamic acid (γ-PGA) through separate hydrolysis and fermentation (SHF), but this process is complicated and generates a lot of wastes. In order to find a simpler and greener way to produce γ-PGA using agricultural wastes, this study attempted to establish simultaneous saccharification and fermentation (SSF) with citric acid-pretreated corn straw. The possibility of Bacillus amyloliquefaciens JX-6 using corn straw as substrate to synthesize γ-PGA was validated, and the results showed that increasing the proportion of glucose in the substrate could improve the γ-PGA yield. Based on these preliminary results, the corn straw was pretreated using citric acid. Then, the liquid fraction (xylan-rich) was used for cultivation of seed culture, and the solid fraction (glucan-rich) was used as the substrate for SSF. In a 10-L fermenter, the maximum cumulative γ-PGA concentration in batch and fed-batch SSF were 5.08 ± 0.78 g/L and 10.78 ± 0.32 g/L, respectively. Moreover, the product from SSF without γ-PGA extraction was used as a fertilizer synergist, increasing the yield of pepper by 13.46% (P < 0.05). Our study greatly simplified the production steps of γ-PGA, and each step achieved zero emission as far as possible. The SSF process for γ-PGA production provided a simple and green way for lignocellulose biorefinery and sustainable cultivation in agriculture

Graphic abstract

Similar content being viewed by others

References

Ogunleye A, Bhat A, Irorere VU, Hill D, Williams C, Radecka I (2015) Poly-γ-glutamic acid: production, properties and applications. Microbiology 161:1–17

Bajaj I, Singhal R (2011) Poly (glutamic acid)-an emerging biopolymer of commercial interest. Bioresour Technol 102:5551–5561

Xu Z, Wan C, Xu X, Feng X, Xu H (2013) Effect of poly (γ-glutamic acid) on wheat productivity, nitrogen use efficiency and soil microbes. J Soil Sci Plant Nutr 13:744–755

Xu Z, Lei P, Feng X, Xu X, Liang J, Chi B, Xu H (2014) Calcium involved in the poly(γ-glutamic acid)-mediated promotion of Chinese cabbage nitrogen metabolism. Plant Physiol Biochem 80:144–152

Lei P, Xu Z, Ding Y, Tang B, Zhang Y, Li H, Feng X, Xu H (2015) Effect of poly(γ-glutamic acid) on the physiological responses and calcium signaling of rape seedlings (Brassica napus L.) under cold stress. J Agric Food Chem 63:10399–10406

Ashiuchi M (2013) Microbial production and chemical transformation of poly-γ-glutamate. Microb Biotechnol 6:664–674

Sirisansaneeyakul S, Cao MF, Kongklom N, Chuensangjun C, Shi ZP, Chisti Y (2017) Microbial production of poly-γ-glutamic acid. World J Microb Biot. https://doi.org/10.1007/s11274-017-2338-y

Jorgensen H, Kristensen JB, Felby C (2007) Enzymatic conversion of lignocellulose into fermentable sugars: challenges and opportunities. Biofuel Bioprod Bior 1:119–134

Hong JL, Ren LJ, Hong JM, Xu CQ (2016) Environmental impact assessment of corn straw utilization in China. J Clean Prod 112:1700–1708

Tang B, Lei P, Xu ZQ, Jiang YX, Xu Z, Liang JF, Feng XH, Xu H (2015) Highly efficient rice straw utilization for poly-(γ-glutamic acid) production by Bacillus subtilis NX-2. Bioresour Technol 193:370–376

Zhu F, Cai J, Zheng Q, Zhu XC, Cen PL, Xu ZN (2014) A novel approach for poly-γ-glutamic acid production using xylose and corncob fibres hydrolysate in Bacillus subtillis HB-1. Chem Technol Biotechnol 89:616–622

Sun JD, Tang C, Zhou J, Wei P, Wang YJ, An W, Yan ZY, Yong XY (2021) Production of poly-γ-glutamic acid (γ-PGA) from xylose-glucose mixtures by Bacillus amyloliquefaciens C1. 3 Biotech 11(2):1–10. https://doi.org/10.1007/s13205-021-02661-7

Rajan K, Carrier DJ (2014) Effect of dilute acid pretreatment conditions and washing on the production of inhibitors and on recovery of sugars during wheat straw enzymatic hydrolysis. Biomass Bioenerg 62:222–227

Takagi M, Abe S, Suzuki S, Emert G, Yata N (1977) A method for production of alcohol directly from cellulose using cellulase and yeast. In: Ghose T (ed) Proceedings of the bioconversion symposium. IIT, New Delhi

Saggi SK, Dey P (2016) An overview of simultaneous saccharification and fermentation of starchy and lignocellulosic biomass for bio-ethanol production. Biofuels. https://doi.org/10.1080/17597269.2016.1193837

Pinaki D, Lhakpa W, Joginder S (2015) Simultaneous saccharification and fermentation (SSF), an efficient process for bio-ethanol production: an overview. Biosci Biotechnol Res Asia 12:87–100

van der Pol EC, Eggink G, Weusthuis RA (2016) Production of L(+)-lactic acid from acid pretreated sugarcane bagasse using Bacillus coagulans DSM2314 in a simultaneous saccharification and fermentation strategy. Biotechnol Biofuels. https://doi.org/10.1186/s13068-016-0646-3

Zheng P, Fang L, Xu Y, Dong JJ, Ni Y, Sun ZH (2010) Succinic acid production from corn stover by simultaneous saccharification and fermentation using Actinobacillus succinogenes. Bioresour Technol 101:7889–7894

Peng X, Zhang C, Tian Y, Guo X, Liu Y, Xiao D (2014) Corncob residue pretreatment for 2,3-Butanediol production by simultaneous saccharification and fermentation. In: Zhang TC, Ouyang P, Kaplan S, Skarnes B (eds) Proceedings of the 2012 International Conference on Applied Biotechnology (ICAB 2012). Springer, Berlin, Heidelberg

Barisik G, Isci A, Kutlu N, Bagder Elmaci S, Akay B (2016) Optimization of organic acid pretreatment of wheat straw. Biotechnol Prog 32:1487–1493

Lee JW, Jeffries TW (2011) Efficiencies of acid catalysts in the hydrolysis of lignocellulosic biomass over a range of combined severity factors. Bioresource Technol 102:5884–5890

Kundu C, Lee HJ, Lee JW (2015) Enhanced bioethanol production from yellow poplar by deacetylation and oxalic acid pretreatment without detoxification. Bioresource Technol 178:28–35

Fang JN, Huan CC, Liu Y, Xu LS, Yan ZY (2020) Bioconversion of agricultural waste into poly-γ-glutamic acid in solid-state bioreactors at different scales. Waste Manage 102:939–948

Olofsson K, Palmqvist B, Lidén G (2010) Improving simultaneous saccharification and co-fermentation of pretreated wheat straw using both enzyme and substrate feeding. Biotechnol Biofuels 3:17

Yong X, Raza W, Yu G, Ran W, Shen Q, Yang X (2011) Optimization of the production of poly-γ-glutamic acid by Bacillus amyloliquefaciens C1 in solid-state fermentation using dairy manure compost and monosodium glutamate production residues as basic substrates. Bioresour Technol 102:7548–7554

Bura R, Chandra R, Saddler J (2009) Influence of xylan on the enzymatic hydrolysis of steam-pretreated corn stover and hybrid poplar. Biotechnol Progr 25:315–322

Yan L, Zhang H, Chen J, Lin Z, Jin Q, Jia H, Huang H (2009) Dilute sulfuric acid cycle spray flow-through pretreatment of corn stover for enhancement of sugar recovery. Bioresour Technol 100:1803–1808

Gorke B, Stulke J (2008) Carbon catabolite repression in bacteria: many ways to make the most out of nutrients. Nat Rev Microbiol 6:613–624

Liu N, Santala S, Stephanopoulos G (2020) Mixed carbon substrates: a necessary nuisance or a missed opportunity? Curr Opin Biotech 62:15–21

Stulke J, Hillen W (2000) Regulation of carbon catabolism in Bacillus species. Annu Rev Microbiol 54:849–880

Stulke J, Hillen W (1999) Carbon catabolite repression in bacteria. Curr Opin Microbiol 2:195–201

Guragain YN, Vadlani PV (2017) 2,3-Butanediol production using Klebsiella oxytoca ATCC 8724: evaluation of biomass derived sugars and fed-batch fermentation process. Process Biochem. https://doi.org/10.1016/j.procbio.2017.05.001

Alkasrawi M, Rudolf A, Lidén G, Zacchi G (2006) Influence of strain and cultivation procedure on the performance of simultaneous saccharification and fermentation of steam pretreated spruce. Enzyme Microb Technol 38:279–286

Dasari RK, Dunaway K, Berson RE (2009) A scraped surface bioreactor for enzymatic saccharification of pretreated corn stover slurries. Energy Fuels 23:492–497

Almeida JR, Modig T, Petersson A, Hähn-Hägerdal B, Lidén G, Gorwa-Grauslund MF (2010) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J chem Technol Biotechnol 82:340–349

Hodge DB, Karim MN, Schell DJ, Mcmillan JD (2009) Model-based fed-batch for high-solids enzymatic cellulose hydrolysis. Appl Biochem Biotechnol 152:88–107

Wang QJ, Chen SW, Zhang JB, Sun M, Liu ZD, Yu ZI (2008) Co-producing lipopeptides and poly-γ-glutamic acid by solid-state fermentation of Bacillus subtilis using soybean and sweet potato residues and its biocontrol and fertilizer synergistic effects. Bioresource Technol 99:3318–3323

Shaukat AA, Tian X, Hussain Q, Singh U (2012) Carbon dioxide emission from maize straw incubated with soil under various moisture and nitrogen levels. J Chem Soc Pakistan 34:22–27

Khalil MI, Gutser R, Schmidhalter U (2009) Effects of urease and nitrification inhibitors added to urea on nitrous oxide emissions from a loess soil. J Plant Nutr Soil Sc 172:651–660

Han WY, Ma LF, Shi YZ, Ruan JY, Kemmitt SJ (2008) Nitrogen release dynamics and transformation of slow release fertiliser products and their effects on tea yield and quality. J Sci Food Agr 88:839–846

Iizumi T, Mizumoto M, Nakamura K (1998) A bioluminescence assay using Nitrosomonas europaea for rapid and sensitive detection of nitrification inhibitors. Appl Environ Microb 64:3656–3662

Majeed Z, Ramli NK, Mansor N, Man Z (2015) A comprehensive review on biodegradable polymers and their blends used in controlled-release fertilizer processes. Rev Chem Eng 31:69–96

Yan XY, Ohara T, Akimoto H (2006) Bottom-up estimate of biomass burning in mainland China. Atmos Environ 40:5262–5273

Zhang HF, Hu DW, Chen JM, Ye XN, Wang SX, Hao JM, Wang L, Zhang RY, An ZS (2011) Particle size distribution and polycyclic aromatic hydrocarbons emissions from agricultural crop residue burning. Environ Sci Technol 45:5477–5482

Lim SL, Lee LH, Wu TY (2016) Sustainability of using composting and vermicomposting technologies for organic solid waste biotransformation: recent overview, greenhouse gases emissions and economic analysis. J Clean Prod 111:262–278

He R, Shao CF, Shi RG, Zhang ZY, Zhao R (2020) Development trend and driving factors of agricultural chemical fertilizer efficiency in China. Sustainability-Basel 12(11):4607. https://doi.org/10.3390/su12114607

Widmer W, Zhou WY, Grohmann K (2010) Pretreatment effects on orange processing waste for making ethanol by simultaneous saccharification and fermentation. Bioresource Technol 101:5242–5249

Acknowledgements

This work was supported by CAS “Light of West China” Program (2019XBZG_XBQNXZ_A_001; 2019XBZG_JCTD_ZDSYS_001), the Grant from Department of Science and Technology of Sichuan Province (2020ZYD023), the Major Science and Technology Projects of Sichuan Province (No. 2018SZDZX0024), and Talent special support from the Organization Department of Sichuan Provincial Party Committee.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ji, G., Xu, L., Lyu, Q. et al. Poly-γ-glutamic acid production by simultaneous saccharification and fermentation using corn straw and its fertilizer synergistic effect evaluation. Bioprocess Biosyst Eng 44, 2181–2191 (2021). https://doi.org/10.1007/s00449-021-02593-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-021-02593-9