Abstract

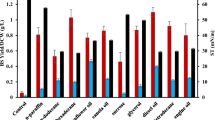

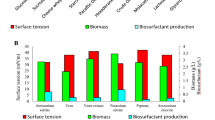

The present study focused on lipopeptide biosurfactant production by Streptomyces sp. PBD-410L in batch and fed-batch fermentation in a 3-L stirred-tank reactor (STR) using palm oil as a sole carbon source. In batch cultivation, the impact of bioprocessing parameters, namely aeration rate and agitation speed, was studied to improve biomass growth and lipopeptide biosurfactant production. The maximum oil spreading technique (OST) result (45 mm) which corresponds to 3.74 g/L of biosurfactant produced, was attained when the culture was agitated at 200 rpm and aeration rate of 0.5 vvm. The best aeration rate and agitation speed obtained from the batch cultivation was adopted in the fed-batch cultivation using DO-stat feeding strategy to further improve the lipopeptide biosurfactant production. The lipopeptide biosurfactant production was enhanced from 3.74 to 5.32 g/L via fed-batch fermentation mode at an initial feed rate of 0.6 mL/h compared to that in batch cultivation. This is the first report on the employment of fed-batch cultivation on the production of biosurfactant by genus Streptomyces.

Similar content being viewed by others

References

Lamilla C, Braga D, Castro R, Guimarães C, de Castilho LV, Freire DM, Barrientos L (2018) Streptomyces luridus So3. 2 from Antarctic soil as a novel producer of compounds with bioemulsification potential. PLoS ONE 13(4):e0196054

de Kronemberger FA, Santa Anna LMM, Fernandes ACLB, de Menezes RR, Borges CP, Freire DMG (2007) Oxygen-controlled biosurfactant production in a bench scale bioreactor. Biotechnology for Fuels and Chemicals. Springer, pp 401–413

Cameotra SS, Makkar RS, Kaur J, Mehta S (2010) Synthesis of biosurfactants and their advantages to microorganisms and mankind. Biosurfactants. Springer, pp 261–280

Vaz DA, Gudina EJ, Alameda EJ, Teixeira JA, Rodrigues LR (2012) Performance of a biosurfactant produced by a Bacillus subtilis strain isolated from crude oil samples as compared to commercial chemical surfactants. Colloids Surf B 89:167–174

Mulligan CN (2005) Environmental applications for biosurfactants. Environ Pollut 133(2):183–198

Mukherjee AK, Das K (2010) Microbial surfactants and their potential applications: an overview. Biosurfactants. Springer, pp 54–64

Manivasagan P, Sivasankar P, Venkatesan J, Sivakumar K, Kim S-K (2014) Optimization, production and characterization of glycolipid biosurfactant from the marine actinobacterium, Streptomyces sp. MAB36. Bioprocess Biosyst Eng 37(5):783–797. https://doi.org/10.1007/s00449-013-1048-6

Richter M, Willey JM, Submuth R, Jung G, Fiedler HP (1998) Streptofactin, a novel biosurfactant with aerial mycelium inducing activity from Streptomyces tendae Tü 901/8c. FEMS Microbiol Lett 163(2):165–171

Khopade A, Ren B, Liu XY, Mahadik K, Zhang L, Kokare C (2012) Production and characterization of biosurfactant from marine Streptomyces species B3. J Colloid Interface Sci 367(1):311–318

Yan X, Sims J, Wang B, Hamann MT (2014) Marine actinomycete Streptomyces sp. ISP2-49E, a new source of rhamnolipid. Biochem Syst Ecol 55:292–295

van Wezel GP, McDowall KJ (2011) The regulation of the secondary metabolism of Streptomyces: new links and experimental advances. Nat Prod Rep 28(7):1311–1333

Zhou Y, Han L-R, He H-W, Sang B, Yu D-L, Feng J-T, Zhang X (2018) Effects of agitation, aeration and temperature on production of a novel glycoprotein GP-1 by Streptomyces kanasenisi ZX01 and scale-up based on volumetric oxygen transfer coefficient. Molecules 23(1):125

Berdy J (2005) Bioactive microbial metabolites. J Antibiot 58(1):1–26

Korayem A, Abdelhafez A, Zaki M, Saleh E (2015) Optimization of biosurfactant production by Streptomyces isolated from Egyptian arid soil using Plackett-Burman design. Ann Agric Sci 60(2):209–217

Santos A, Silva M, Costa E, Rufino R, Santos V, Ramos C, Sarubbo L, Porto A (2018) Production and characterization of a biosurfactant produced by Streptomyces sp. DPUA 1559 isolated from lichens of the Amazon region. Braz J Med Biol Res. 51(2):e6657. https://doi.org/10.1590/1414-431x20176657

Oliveira FJS, Vazquez L, de Campos NP, de França FP (2006) Biosurfactants production by Pseudomonas aeruginosa FR using palm oil. In: McMillan JD, Adney WS, Mielenz JR, Klasson KT (eds) Twenty-Seventh Symposium on Biotechnology for Fuels and Chemicals. Humana Press, Totowa, NJ, pp 727–737. https://doi.org/10.1007/978-1-59745-268-7_59

Vanavil B, Perumalsamy M, Rao AS (2013) Biosurfactant production from novel air isolate NITT6L: Screening, characterization and optimization of media. J Microbiol Biotechnol 23(9):1229–1243

Sarachat T, Pornsunthorntawee O, Chavadej S, Rujiravanit R (2010) Purification and concentration of a rhamnolipid biosurfactant produced by Pseudomonas aeruginosa SP4 using foam fractionation. Biores Technol 101(1):324–330. https://doi.org/10.1016/j.biortech.2009.08.012

Poomtien J, Thaniyavarn J, Pinphanichakarn P, Jindamorakot S, Morikawa M (2013) Production and characterization of a biosurfactant from Cyberlindnera samutprakarnensis JP52(T). Biosci Biotechnol Biochem 77(12):2362–2370. https://doi.org/10.1271/bbb.130434

Saharan B, Sahu R (2011) Sharma D (2011) A review on biosurfactants: fermentation, current developments and perspectives. Genet Eng Biotechnol J 1:1–14

Nurfarahin A, Mohamed M, Phang L (2018) Culture medium development for microbial-derived surfactants production—an overview. Molecules 23(5):1049

Nelofer R, Rahman ZRA, Noor R, Basri M, Ariff AB (2013) Optimization of fed-batch fermentation for organic solvent tolerant and thermostable lipase production from recombinant E. coli. Turk J Biochem 38(3):299

Kronemberger FA, Borges CP, Freire DM (2010) Fed-batch biosurfactant production in a bioreactor. Int Rev Chem Eng 2(4):513–518

Sivapathasekaran C, Sen R (2013) Performance evaluation of batch and unsteady state fed-batch reactor operations for the production of a marine microbial surfactant. J Chem Technol Biotechnol 88(4):719–726

Hajfarajollah H, Mokhtarani B, Tohidi A, Bazsefidpar S, Akbari Noghabi K (2019) Overproduction of lipopeptide biosurfactant by Aneurinibacillus thermoaerophilus HAK01 in various fed-batch modes under thermophilic conditions. RSC Adv 9(52):30419–30427. https://doi.org/10.1039/C9RA02645B

Yao S, Zhao S, Lu Z, Gao Y, Lv F, Bie X (2015) Control of agitation and aeration rates in the production of surfactin in foam overflowing fed-batch culture with industrial fermentation. Rev Argent Microbiol 47(4):344–349. https://doi.org/10.1016/j.ram.2015.09.003

Rusly NS (2019) Production and characterization of biosurfactant produced by mangrove Streptomyces sp. PBD-410L. M. S. Thesis, Universiti Sains Malaysia, Penang, Malaysia

Costa SG, Lépine F, Milot S, Déziel E, Nitschke M, Contiero J (2009) Cassava wastewater as a substrate for the simultaneous production of rhamnolipids and polyhydroxyalkanoates by Pseudomonas aeruginosa. J Ind Microbiol Biotechnol 36(8):1063–1072

Nur Asshifa MN, Zambry NS, Salwa MS, Yahya ARM (2017) The influence of agitation on oil substrate dispersion and oxygen transfer in Pseudomonas aeruginosa USM-AR2 fermentation producing rhamnolipid in a stirred tank bioreactor. 3 Biotech 7(3):1–11. https://doi.org/10.1007/s13205-017-0828-0

Müller JM, Risse JM, Jussen D, Flaschel E (2013) Development of fed-batch strategies for the production of streptavidin by Streptomyces avidinii based on power input and oxygen supply studies. J Biotechnol 163(3):325–332

Zambry NS, Rusly NS, Awang MS, Md. Noh NA, Mohd AR (2018) Bioprocessing influences lipopeptide biosurfactant production in Streptomyces sp. PBD-410L. trans. AFOB Malaysia Chapter International Symposium 2018, Asian Federation of Biotechnology Malaysia Chapter International Symposium, Pullman Hotels and Resorts Kuching, Sarawak, Malaysia

Youssef NH, Duncan KE, Nagle DP, Savage KN, Knapp RM, McInerney MJ (2004) Comparison of methods to detect biosurfactant production by diverse microorganisms. J Microbiol Methods 56(3):339–347. https://doi.org/10.1016/j.mimet.2003.11.001

Kamble A, Meena V, Banerjee U (2010) Effect of agitation and aeration on the production of nitrile hydratase by Rhodococcus erythropolis MTCC 1526 in a stirred tank reactor. Lett Appl Microbiol 51(4):413–420

Elsayed EA, Omar HG, El-Enshasy HA (2015) Development of fed-batch cultivation strategy for efficient oxytetracycline production by Streptomyces rimosus at semi-industrial scale. Braz Arch Biol Technol 58(5):676–685

Rioseras B, López-García MT, Yagüe P, Sánchez J, Manteca Á (2014) Mycelium differentiation and development of Streptomyces coelicolor in lab-scale bioreactors: programmed cell death, differentiation, and lysis are closely linked to undecylprodigiosin and actinorhodin production. Biores Technol 151:191–198

Rahulan R, Dhar KS, Nampoothiri KM, Pandey A (2011) Production of leucine amino peptidase in lab scale bioreactors using Streptomyces gedanensis. Biores Technol 102(17):8171–8178

Viana Marques DA, Santos-Ebinuma VC, Pessoa-Junior A, Porto AL, Torres BR, Converti A (2016) Effect of aeration and agitation on extractive fermentation of clavulanic acid by using aqueous two-phase system. Biotechnol Prog 32(6):1444–1452. https://doi.org/10.1002/btpr.2333

Rane AN, Baikar VV, Ravi Kumar V, Deopurkar RL (2017) Agro-industrial wastes for production of biosurfactant by Bacillus subtilis ANR 88 and its application in synthesis of silver and gold nanoparticles. Front Microbiol. https://doi.org/10.3389/fmicb.2017.00492

Balan SS, Kumar CG, Jayalakshmi S (2017) Aneurinifactin, a new lipopeptide biosurfactant produced by a marine Aneurinibacillus aneurinilyticus SBP-11 isolated from Gulf of Mannar: Purification, characterization and its biological evaluation. Microbiol Res 194:1–9. https://doi.org/10.1016/j.micres.2016.10.005

Silva JPA, Mussatto SI, Roberto IC (2010) The influence of initial xylose concentration, agitation, and aeration on ethanol production by Pichia stipitis from rice straw hemicellulosic hydrolysate. Appl Biochem Biotechnol 162(5):1306–1315

Brumano LP, Antunes FAF, Souto SG, dos Santos JC, Venus J, Schneider R, da Silva SS (2017) Biosurfactant production by Aureobasidium pullulans in stirred tank bioreactor: New approach to understand the influence of important variables in the process. Biores Technol 243:264–272

Ghribi D, Ellouze-Chaabouni S (2011) Enhancement of Bacillus subtilis lipopeptide biosurfactants production through optimization of medium composition and adequate control of aeration. Biotechnol Res Int 2011. https://doi.org/10.4061/2011/653654

Lee JY, Kang SW, Kim SW (2008) Relationship between agitation speed and the morphological characteristics of Verticillium lecanii CS-625 during spore production. Biotechnol Bioprocess Eng 13(1):1–6

Moutafchieva D, Popova D, Dimitrova M, Tchaoushev S (2013) Experimental determination of the volumetric mass transfer coefficient. J Chem Technol Metall 48(4):351–356

Michelin M, de Oliveira Mota AM, de Moraes MdLT, da Silva DP, Vicente AA, Teixeira JA (2013) Influence of volumetric oxygen transfer coefficient (kLa) on xylanases batch production by Aspergillus niger van Tieghem in stirred tank and internal-loop airlift bioreactors. Biochem Eng J 80:19–26

Xia X, Lin S, Xia X-X, Cong F-S, Zhong J-J (2014) Significance of agitation-induced shear stress on mycelium morphology and lavendamycin production by engineered Streptomyces flocculus. Appl Microbiol Biotechnol 98(10):4399–4407

Zambry NS, Ayoib A, Md Noh NA, Yahya ARM (2017) Production and partial characterization of biosurfactant produced by Streptomyces sp. R1. Bioprocess Biosyst Eng 40(7):1007–1016. https://doi.org/10.1007/s00449-017-1764-4

Zhu L, Yang X, Xue C, Chen Y, Qu L, Lu W (2012) Enhanced rhamnolipids production by Pseudomonas aeruginosa based on a pH stage-controlled fed-batch fermentation process. Biores Technol 117:208–213. https://doi.org/10.1016/j.biortech.2012.04.091

Shavandi M, Mohebali G, Haddadi A, Shakarami H, Nuhi A (2011) Emulsification potential of a newly isolated biosurfactant-producing bacterium, Rhodococcus sp. strain TA6. Colloids Surf B Biointerfaces 82(2):477–482. https://doi.org/10.1016/j.colsurfb.2010.10.005

Dhasayan A, Selvin J, Kiran S (2015) Biosurfactant production from marine bacteria associated with sponge Callyspongia diffusa. 3 Biotech 5(4):443–454

Kalyani A, Girija S, Prabhakar T (2014) Optimization of rhamnolipid biosurfactant production by Streptomyces matensis (NBRC 12889 T) using Plackett-Burman design. J Biomed Pharm Res 3:1–7

Fooladi T, Abdeshahian P, Moazami N, Soudi MR, Kadier A, Yusoff WMW, Hamid AA (2018) Enhanced biosurfactant production by Bacillus pumilus 2IR in fed-batch fermentation using 5-l bioreactor. Iran J Sci Technol Trans A Sci 42(3):1111–1123. https://doi.org/10.1007/s40995-018-0599-4

Zhu X, Zhang W, Chen X, Wu H, Duan Y, Xu Z (2010) Generation of high rapamycin producing strain via rational metabolic pathway-based mutagenesis and further titer improvement with fed-batch bioprocess optimization. Biotechnol Bioeng 107(3):506–515. https://doi.org/10.1002/bit.22819

Acknowledgement

This research was financially supported by Research University Grant (1001/PBIOLOGI /815103) and Special Bridging Grant (304.PBIOLOG1.6316217), Universiti Sains Malaysia, Malaysia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zambry, N.S., Rusly, N.S., Awang, M.S. et al. Production of lipopeptide biosurfactant in batch and fed-batch Streptomyces sp. PBD-410L cultures growing on palm oil. Bioprocess Biosyst Eng 44, 1577–1592 (2021). https://doi.org/10.1007/s00449-021-02543-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-021-02543-5