Abstract

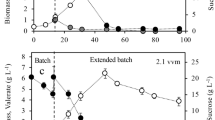

In the present study, the production of poly(3-hydroxybutyrate-co-3–hydroxyvalerate) (PHBV) by Azotobacter vinelandii was evaluated in shake flasks and bioreactors, utilizing different precursors and oxygen transfer rates (OTRs). In shake flask cultures, the highest PHBV yield from sucrose (0.16 g g–1) and 3-hydroxyvalerate (3HV) fraction in the PHA chain (27.4 mol%) were obtained with valerate (1.0 g L−1). In the bioreactor, the cultures were grown under oxygen-limited conditions, and the maximum OTR (OTRmax) was varied by adjusting the agitation rate. In the cultures grown at low OTRmax (4.3 mmol L−1 h−1), the intracellular content of PHBV (73% w w−1) was improved, whereas a maximum 3HV fraction (35 mol %) was obtained when a higher OTRmax (17.2 mmol L−1 h−1, to 600 rpm) was employed. The findings obtained suggest that the PHBV production and the content of 3HV incorporated into the polymer were affected by the OTR. Based on the evidence, it is possible to produce PHBV with a different composition by varying the OTR of the culture; thus, the approach in this study could be used to scale up PHBV production.

Similar content being viewed by others

References

Khanna S, Srivastava AK (2005) Recent advances in microbial polyhydroxyalkanoates. Process Biochem 40:607–619

Philip S, Keshavarz T, Roy I (2007) Polyhydroxyalkanoates: biodegradable polymers with a range of applications. J Chem Technol Biotechnol 82(3):233–247

Steinbüchel A, Lütke-Everslok T (2003) Metabolic engineering and pathway construction for biotechnological production of relevant polyhydroxyalkanoates in microorganisms. Biochem Eng J 16:81–96

Peña C, Castillo T, García A, Millán M, Segura D (2014) Biotechnological strategies to improve production of microbial poly-(3-hydroxybutyrate): a review of recent research work. Microb Biotechnol 7:278–293

Domínguez-Díaz M, Meneses-Acosta A, Romo-Uribe A, Peña C, Segura D, Espin G (2015) Thermo-mechanical properties, microstructure and biocompatibility in poly-β-hydroxybutyrate (PHB) produced by OP and OPN strains of Azotobacter vinelandii. Eur Polym J 63:101–112

Madison LL, Huisman GW (1999) Metabolic engineering of poly(3-hydroxyalkanoates): from DNA to plastic. Microbiol Mol Biol Rev 63(1):21–53

Rivera-Briso AL, Serrano-Aroca A (2018) Poly(3-hydroxybutyrate-co-3-hydroxyvalerate): enhancement strategies for advanced applications. Polymers 10:732–759

Savenkova L, Gercberga Z, Bibers I, Kalnin M (2000) Effect of 3-hydroxy valerate content on some physical and mechanical properties of polyhydroxyalkanoates produced by Azotobacter chroococcum. Process Biochem 36:445–450

Suwantong O, Waleetorncheepsawat S, Sanchavanakit N, Pavasant P, Cheepsunthorn P, Bunaprasert T, Supaphol P (2007) In vitro biocompatibility of electrospun poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) fiber mats. Int J Biol Macromol 40(3):217–223

Braunegg G, Lefebvre G, Genser KF (1998) Polyhydroxyalkanoates, biopolyesters from renewable resources: physiological and engineering aspects. J Biotechnol 65:127–161

Valentin HE, Berger PA, Gruys KJ, Andrade Rodrigues MF, Steinbüchel A, Tran M, Asrar J (1999) Biosynthesis and characterization of poly(3-hydroxy-4-pentenoic acid). Macromolecules 32(22):7389–7395

Wang Y, Chen R, Cai J, Liu Z, Zheng Y, Wang H, Li Q, He N (2013) Biosynthesis and thermal properties of PHBV produced from levulinic acid by Ralstonia eutropha. PLoS One 8(4):e60318

Zhang YZ, Liu GM, Weng WQ, Ding JY, Liu SJ (2015) Engineering of Ralstonia eutropha for the production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) from glucose. J Biotechnol 10(195):82–88

Aldor IS, Kim SW, Prather KL, Keasling JD (2002) Metabolic engineering of a novel propionate-independent pathway for the production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) in recombinant Salmonella enterica serovar typhimurium. Appl Environ Microbiol 68(8):3848–3854

Galindo E, Peña C, Núñez C, Segura D, Espín G (2007) Molecular and bioengineering strategies to improve alginate and polyhydroxyalkanoate production by Azotobacter vinelandii. Microb Cell Fact 6(7):1–16

Chen CQ, Jiang XR (2018) Engineering microorganisms for improving polyhydroxyalkanoate biosynthesis. Curr Opin Biotechnol 53:20–25

Page WJ, Manchak J, Rudy B (1992) Formation of poly(hydroxybutyrate-co-hydroxyvalerate) by Azotobacter vinelandii UWD. Appl Environ Microbiol 58(9):2866–2873

Blunt W, Sparling R, Gapes DJ, Levin DB, Cicek N (2018) The role of dissolved oxygen content as a modulator of microbial polyhydroxyalkanoate synthesis. World J Microbiol Biotechnol 34:106–118

Cho KS, Ryu HW, Park CH, Goodrich P (2001) Utilization of swine wastewater as a feedstock for the production of polyhydroxyalkanoates by Azotobacter vinelandii UWD. J Biosci Bioeng 91(2):129–133

Myshkina VL, Ivanov EA, Nikolaeva DA, Makhina TK, Bonartsev AP, Filatova EV, Ruzhitsky AO, Bonartseva GA (2010) Biosynthesis of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) copolymer by Azotobacter chroococcum strain 7B. Appl Biochem Microbiol 46:289–296

Bonartsev AP, Bonartseva GA, Myshkina VL, Voinova VV, Mahina TK, Zharkova II, Yakovlev SG, Zernov AL, Ivanova EV, Akoulina EA, Kuznetsova ES, Zhuikov VA, Alekseeva SG, Podgorskii VV, Bessonov IV, Koptsyna MN, Morozov AS, Milanovskiy EY, Tyugay ZN, Bykova GS, Kirpichnikov MP, Shoaitan KV (2016) Biosynthesis of poly(3-hydroxybutyrate-co-3-hydroxy-4-methylvalerate) by strain Azotobacter chroococcum 7B. Acta Naturae 8(3):77–87

Díaz-Barrera A, Peña C, Galindo E (2007) The oxygen transfer rate influences the molecular mass of the alginate produced by Azotobacter vinelandii. Appl Microbiol Biotechnol 76(4):903–910

Díaz-Barrera A, Gutierrez J, Martínez F, Altamirano C (2014) Production of alginate by Azotobacter vinelandii grown at two bioreactor scales under oxygen-limited conditions. Bioprocess Biosys Eng 37:1133–1140

Riis V, Mai W (1988) Gas chromatographic determination of poly-β-hydroxybutyric acid in microbial biomass after hydrochloric acid propanolysis. J Chromatogr A 445:285–289

Mendonça TT, Gomez JGC, Buffoni E, Sánchez Rodriguez RJ, Schripsema J, Lopes MSG, Silva LF (2014) Exploring the potential of Burkholderia sacchari to produce polyhydroxyalkanoates. J Appl Microbiol 116:815–829

Urtuvia V, Villegas P, Fuentes S, González M, Seeger M (2018) Burkholderia xenovorans LB400 possesses a functional polyhydroxyalkanoate anabolic pathway encoded by the pha genes and synthesizes poly(3-hydroxybutyrate) under nitrogen-limiting conditions. Int Microbiol 461:1–11

Dhanasekar R, Viruthagiri T (2005) Batch Kinetics and modeling of poly-β-hydroxy butyrate synthesis from Azotobacter vinelandii using different carbon sources. Ind J Chem Technol 12:322–326

De Paula FC, Kakazu S, De Paula CBC, De Almeida AF, Gomez JGC, Conteiro J (2019) Burkholderia glumae MA13: a newly isolated bacterial strain suitable for polyhydroxyalkanoates production from crude glycerol. Biocatal Agric Biotechnol 20:101268–101278

Tao W, Lv L, Chen GQ (2017) Engineering Halomonas species TD01 for enhanced polyhydroxyalkanoates synthesis via CRISPRi. Microb Cell Fact 16:48–57

Solaiman DK, Ashby RD, Foglia TA, Marmer WN (2006) Conversion of agricultural feedstock and coproducts into poly(hydroxyalkanoate). Appl Microbiol Biotechnol 71:783–789

Igarashi RY, Dos Santos PC, Niehaus WG, Dance IG, Dean DR, Seefeldt LC (2004) Localization of a catalytic intermediate bound to the FeMo-cofactor of nitrogenase. J Biol Chem 279(33):34770–34775

Nurbas M, Kutsal T (2004) Production of PHB and P(HB-co-HV) biopolymers by using Alcaligenes eutrophus. Iran Polym J 13(1):45–51

Díaz-Barrera A, Andler R, Martínez I, Peña C (2016) Poly-3-hydroxybutyrate production by Azotobacter vinelandii strains in batch cultures at different oxygen transfer rates. J Chem Technol Biotechnol 91:1063–1071

Garcia-Ochoa F, Gomez E, Alcon A, Santos VE (2013) The effect of hydrodynamic stress on the growth of Xanthomonas campestris cultures in a stirred and sparged tank bioreactor. Bioprocess Biosyst Eng 36:911–925

Wewetzer SJ, Kunze M, Ladner T, Luchterhand B, Roth S, Rahmen N, KloßCosta e Silva RA, Regestein L, Büchs J (2015) Parallel use of shake flask and microtiter plate online measuring devices (RAMOS and BioLector) reduces the number of experiments in laboratory-scale stirred tank bioreactors. J Biomed Eng 9:9–26

García A, Ferrer P, Albiol J, Castillo T, Segura D, Peña C (2018) Metabolic flux analysis and the NAD(P)H/NAD(P)+ ratios in chemostat cultures of Azotobacter vinelandii. Microb Cell Fact 17:10–23

Lee WH, Azizan MNM, Sudesh K (2004) Effects of culture conditions on the composition of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) synthesized by Comamonas acidovorans. Polym Degrad Stabil 84:129–134

Cavalheiro JM, Raposo RS, Almeida MC, Cesário MT, Sevrin C, Grandfils C, da Fonseca MM (2012) Effect of cultivation parameters on the production of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and poly(3-hydroxybutyrate-4-hydroxybutyrate-3-hydroxyvalerate) by Cupriavidus necator using waste glycerol. Bioresour Technol 111:391–397

Lefebvre G, Rocher M, Braunegg G (1997) Effects of low dissolved-oxygen concentrations on poly-(3-hydroxybutyrate-co-3-hydroxyvalerate) production by Alcaligenes eutrophus. Appl Environ Microbiol 63(3):827–833

Kim YB, Lenz RW (2001) Polyesters from microorganisms. In: Babel W, Steinbüchel A (eds) Biopolyesters. Advances in biochemical engineering/biotechnology, vol 71. Springer, Berlin, pp 51–79

Doi Y, Kunioka M, Nakamura Y, Soga K (1987) Biosynthesis of copolyester in Alcaligenes eutrophus H16 from 13C-labeled acetate and propionate. Macromolecules 20:2988–2991

Acknowledgements

The authors acknowledge support from CONICYT-FONDECYT Postdoctoral project 3180406 (VU) and CONICYT-FONDECYT Regular project 1170896 (AD). The authors would like to thank to the Regional Center for Studies in Healthy Food (CREAS) for their support in with gas chromatography–mass spectrometry (GC–MS) and Ph.D. German Aroca for support Elite-5MS column for GC–MS.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Urtuvia, V., Maturana, N., Peña, C. et al. Accumulation of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Azotobacter vinelandii with different 3HV fraction in shake flasks and bioreactor. Bioprocess Biosyst Eng 43, 1469–1478 (2020). https://doi.org/10.1007/s00449-020-02340-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-020-02340-6