Abstract

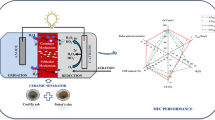

A conventional reactor in microbial electrochemical technology (MET) consists of anode and cathode compartments divided by a separator, which is usually a proton exchange membrane (PEM), such as Nafion 117. In this study, a novel porous clay earthenware (NCE) was fabricated as the separator to replace the highly cost PEM. The fabrication of NCEs is with raw clay powder and starch powder that acts as a pore-forming agent at different starch powder contents (10 vol%, 20 vol%, and 30 vol%), ball-milled before hydraulically pressed to form green ceramic pellets and sintered up to 1200 °C. The highest power density of 2250 ± 21 mW/m2 (6.0 A/m2), the internal resistance of 75 ± 24 Ω and coulombic efficiency (CE) of 44 ± 21% were produced for MFC–NCE from 30 vol% starch powder content under batch mode operation. The MFC–PEM combination produced the lowest power density, CE and the highest internal resistance up to 1350 ± 17 mW/m2 (3.0 A/m2), 23 ± 15% and 326 ± 13 Ω, respectively.

Similar content being viewed by others

References

Owusu PA, Asumadu-Sarkodie S (2016) A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Eng 3(1):1167990. https://doi.org/10.1080/23311916.2016.1167990

Enzmann F, Mayer F, Stöckl M, Mangold K-M, Hommel R, Holtmann D (2019) Transferring bioelectrochemical processes from H-cells to a scalable bubble column reactor. Chem Eng Sci 193:133–143. https://doi.org/10.1016/j.ces.2018.08.056

Shamsuddin RaA, Abu Bakar MH, Wan Daud WR, Hong KB, Jahim JM (2019) Can electrochemically active biofilm protect stainless steel used as electrodes in bioelectrochemical systems in a similar way as galvanic corrosion protection? Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2019.03.089

McCarty PL, Bae J, Kim J (2011) Domestic wastewater treatment as a net energy producer—can this be achieved? Environ Sci Technol 45(17):7100–7106. https://doi.org/10.1021/es2014264

Martinez SM, Di Lorenzo M (2019) Electricity generation from untreated fresh digestate with a cost-effective array of floating microbial fuel cells. Chem Eng Sci 198:108–116. https://doi.org/10.1016/j.ces.2018.12.039

Winfield J, Gajda I, Greenman J, Ieropoulos I (2016) A review into the use of ceramics in microbial fuel cells. Bioresour Technol 215:296–303. https://doi.org/10.1016/j.biortech.2016.03.135

Li W-W, Sheng G-P, Liu X-W, Yu H-Q (2011) Recent advances in the separators for microbial fuel cells. Bioresour Technol 102(1):244–252. https://doi.org/10.1016/j.biortech.2010.03.090

Kondaveeti S, Abu-Reesh IM, Mohanakrishna G, Pant D, He Z (2019) Utilization of residual organics of Labaneh whey for renewable energy generation through bioelectrochemical processes: Strategies for enhanced substrate conversion and energy generation. Bioresour Technol 286:121409. https://doi.org/10.1016/j.biortech.2019.121409

Rahimnejad M, Adhami A, Darvari S, Zirepour A, Oh S-E (2015) Microbial fuel cell as new technology for bioelectricity generation: a review. Alex Eng J 54(3):745–756. https://doi.org/10.1016/j.aej.2015.03.031

Yousefi V, Mohebbi-Kalhori D, Samimi A (2017) Ceramic-based microbial fuel cells (MFCs): a review. Int J Hydrogen Energy 42(3):1672–1690. https://doi.org/10.1016/j.ijhydene.2016.06.054

Zhang G, Zhao Q, Jiao Y, Lee D-J (2015) Long-term operation of manure-microbial fuel cell. Bioresour Technol 180:365–369. https://doi.org/10.1016/j.biortech.2015.01.002

Rozendal RA, Hamelers HVM, Buisman CJN (2006) Effects of membrane cation transport on pH and microbial fuel cell performance. Environ Sci Technol 40(17):5206–5211. https://doi.org/10.1021/es060387r

Rozendal RA, Sleutels THJA, Hamelers HVM, Buisman CJN (2008) Effect of the type of ion exchange membrane on performance, ion transport, and pH in biocatalyzed electrolysis of wastewater. Water Sci Technol 57(11):1757

Daud SM, Daud WRW, Kim BH, Somalu MR, Bakar MHA, Muchtar A, Jahim JM, Lim SS, Chang IS (2018) Comparison of performance and ionic concentration gradient of two-chamber microbial fuel cell using ceramic membrane (CM) and cation exchange membrane (CEM) as separators. Electrochim Acta 259:365–376. https://doi.org/10.1016/j.electacta.2017.10.118

Daud SM, Kim BH, Ghasemi M, Daud WRW (2015) Separators used in microbial electrochemical technologies: current status and future prospects. Bioresour Technol 195:170–179. https://doi.org/10.1016/j.biortech.2015.06.105

Ortiz-Martínez VM, Gajda I, Salar-García MJ, Greenman J, Hernández-Fernández FJ, Ieropoulos I (2016) Study of the effects of ionic liquid-modified cathodes and ceramic separators on MFC performance. Chem Eng J 291:317–324. https://doi.org/10.1016/j.cej.2016.01.084

Lee M, Wu Z, Li K (2015) 2-advances in ceramic membranes for water treatment. In: Basile A, Cassano A, Rastogi NK (eds) Advances in membrane technologies for water treatment. Woodhead Publishing, Oxford, pp 43–82. https://doi.org/10.1016/B978-1-78242-121-4.00002-2

Daud SM, Wan Daud WR, Abu Bakar MH, Kim BH, Somalu MR, Jahim JM, Muchtar A, Ghasemi M (2019) A comparison of long-term fouling performance by zirconia ceramic filter and cation exchange in microbial fuel cells. Int Biodeterior Biodegrad 136:63–70. https://doi.org/10.1016/j.ibiod.2018.11.001

Behera M, Ghangrekar MM (2011) Electricity generation in low cost microbial fuel cell made up of earthenware of different thickness. Water Sci Technol 64(12):2468

Behera M, Jana PS, Ghangrekar MM (2010) Performance evaluation of low cost microbial fuel cell fabricated using earthen pot with biotic and abiotic cathode. Bioresour Technol 101(4):1183–1189. https://doi.org/10.1016/j.biortech.2009.07.089

Winfield J, Chambers LD, Rossiter J, Ieropoulos I (2013) Comparing the short and long term stability of biodegradable, ceramic and cation exchange membranes in microbial fuel cells. Bioresour Technol 148:480–486. https://doi.org/10.1016/j.biortech.2013.08.163

Pasternak G, Greenman J, Ieropoulos I (2016) comprehensive study on ceramic membranes for low-cost microbial fuel cells. Chemsuschem 9(1):88–96. https://doi.org/10.1002/cssc.201501320

Gregorová E, Živcová Z, Pabst W (2009) Starch as a pore-forming and body-forming agent in ceramic technology. Starch-Stärke 61(9):495–502. https://doi.org/10.1002/star.200900138

Li S, Wang C-A, Zhou J (2013) Effect of starch addition on microstructure and properties of highly porous alumina ceramics. Ceram Int 39(8):8833–8839. https://doi.org/10.1016/j.ceramint.2013.04.072

Chae KJ, Choi M, Ajayi FF, Park W, Chang IS, Kim IS (2008) Mass transport through a proton exchange membrane (Nafion) in microbial fuel cells. Energy Fuels 22(1):169–176. https://doi.org/10.1021/ef700308u

Lim SS, Daud WRW, Md Jahim J, Ghasemi M, Chong PS, Ismail M (2012) Sulfonated poly(ether ether ketone)/poly(ether sulfone) composite membranes as an alternative proton exchange membrane in microbial fuel cells. Int J Hydrogen Energy 37(15):11409–11424. https://doi.org/10.1016/j.ijhydene.2012.04.155

Leong JX, Daud WRW, Ghasemi M, Ahmad A, Ismail M, Liew KB (2015) Composite membrane containing graphene oxide in sulfonated polyether ether ketone in microbial fuel cell applications. Int J Hydrogen Energy 40(35):11604–11614. https://doi.org/10.1016/j.ijhydene.2015.04.082

Logan BE (2009) Exoelectrogenic bacteria that power microbial fuel cells. Nat Rev Micro 7(5):375–381

Kim BH, Kim H-J, Park D-H (1999) Direct electrode reaction of Fe(III)-reducing bacterium, shewanella putrefaciens. Microbiol Biotechnol 9(2):127–131

Choi S, Kim JR, Cha J, Kim Y, Premier GC, Kim C (2013) Enhanced power production of a membrane electrode assembly microbial fuel cell (MFC) using a cost effective poly [2,5-benzimidazole] (ABPBI) impregnated non-woven fabric filter. Bioresour Technol 128:14–21. https://doi.org/10.1016/j.biortech.2012.10.013

Oliot M, Galier S, Roux-de Balmann H, Bergel A (2016) Ion Transport in microbial fuel cells: key roles, theory and critical review. Appl Energy. https://doi.org/10.1016/j.apenergy.2016.09.043

Hamrock SJ, Yandrasits MA (2006) Proton exchange membranes for fuel cell applications. J Macromol Sci Part C 46(3):219–244. https://doi.org/10.1080/15583720600796474

Walter XA, Gajda I, Forbes S, Winfield J, Greenman J, Ieropoulos I (2016) Scaling-up of a novel, simplified MFC stack based on a self-stratifying urine column. Biotechnol Biofuels 9(1):93. https://doi.org/10.1186/s13068-016-0504-3

Kuchi S, Sarkar O, Butti SK, Velvizhi G, Venkata Mohan S (2018) Stacking of microbial fuel cells with continuous mode operation for higher bioelectrogenic activity. Bioresour Technol 257:210–216. https://doi.org/10.1016/j.biortech.2018.02.057

Wu S, Li H, Zhou X, Liang P, Zhang X, Jiang Y, Huang X (2016) A novel pilot-scale stacked microbial fuel cell for efficient electricity generation and wastewater treatment. Water Res 98:396–403. https://doi.org/10.1016/j.watres.2016.04.043

Winfield J, Greenman J, Huson D, Ieropoulos I (2013) Comparing terracotta and earthenware for multiple functionalities in microbial fuel cells. Bioprocess Biosyst Eng 36(12):1913–1921. https://doi.org/10.1007/s00449-013-0967-6

Chouler J, Padgett GA, Cameron PJ, Preuss K, Titirici M-M, Ieropoulos I, Di Lorenzo M (2016) Towards effective small scale microbial fuel cells for energy generation from urine. Electrochim Acta 192:89–98. https://doi.org/10.1016/j.electacta.2016.01.112

Wang B, Han J-I (2008) A single chamber stackable microbial fuel cell with air cathode. Biotechnol Lett 31:387–393. https://doi.org/10.1007/s10529-008-9877-0

Pasupuleti SB, Srikanth S, Dominguez-Benetton X, Mohan SV, Pant D (2016) Dual gas diffusion cathode design for microbial fuel cell (MFC): optimizing the suitable mode of operation in terms of bioelectrochemical and bioelectro-kinetic evaluation. J Chem Technol Biotechnol 91(3):624–639. https://doi.org/10.1002/jctb.4613

Pasupuleti SB, Sandipam S, Dominguez-Benetton X, Venkata Mohan S, Pant D (2014) Dual gas diffusion cathode design for microbial fuel cell (MFC): optimizing the suitable mode of operation in terms of bioelectrochemical and bioelectro-kinetic evaluation. J Chem Technol Biotechnol 91:624–639

Mathuriya AS, Pant D (2019) Assessment of expanded polystyrene as a separator in microbial fuel cell. Environ Technol 40(16):2052–2061. https://doi.org/10.1080/09593330.2018.1435740

Zhang X, Cheng S, Huang X, Logan BE (2010) The use of nylon and glass fiber filter separators with different pore sizes in air-cathode single-chamber microbial fuel cells. Energy Environ Sci 3:659–664. https://doi.org/10.1039/b927151a

Du JR, Peldszus S, Huck PM, Feng X (2015) Modification of membrane surfaces via microswelling for fouling control in drinking water treatment. J Membr Sci 475:488–495. https://doi.org/10.1016/j.memsci.2014.10.040

Hiegemann H, Littfinski T, Krimmler S, Lübken M, Klein D, Schmelz K-G, Ooms K, Pant D, Wichern M (2019) Performance and inorganic fouling of a submergible 255 L prototype microbial fuel cell module during continuous long-term operation with real municipal wastewater under practical conditions. Bioresour Technol 294:122227. https://doi.org/10.1016/j.biortech.2019.122227

Sekar N, Ramasamy RP (2013) Electrochemical impedance spectroscopy for microbial fuel cell characterization. J Microb Biochem Technol S 6(2):1–14. https://doi.org/10.4172/1948-5948.S6-004

Kondaveeti S, Lee J, Kakarla R, Kim HS, Min B (2014) Low-cost separators for enhanced power production and field application of microbial fuel cells (MFCs). Electrochim Acta 132:434–440. https://doi.org/10.1016/j.electacta.2014.03.046

Babauta J, Renslow R, Lewandowski Z, Beyenal H (2012) Electrochemically active biofilms: facts and fiction. A review. Biofouling 28(8):789–812. https://doi.org/10.1080/08927014.2012.710324

Acknowledgements

The authors appreciate the financial support offered by Universiti Kebangsaan Malaysia through several research Grants (03–01-02-SF0985, GUP-2015–036, and FRGS/1/2014/TK06/UKM/03/1).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Daud, S.M., Daud, W.R.W., Bakar, M.H.A. et al. Low-cost novel clay earthenware as separator in microbial electrochemical technology for power output improvement. Bioprocess Biosyst Eng 43, 1369–1379 (2020). https://doi.org/10.1007/s00449-020-02331-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-020-02331-7