Abstract

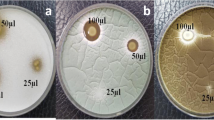

Pseudomonas taetrolens constitutes an efficient platform for the biosynthesis of lactobionic acid, a potentially prebiotic compound. Unfortunately, an amensalistic interaction has been demonstrated between P. taetrolens and probiotic lactic acid bacteria (LAB), characterized by the competitive exclusion of P. taetrolens, hindering the in situ production of fermented dairy products with synbiotic properties. In the present research, encapsulation was explored as a barrier to the diffusion of the antimicrobial metabolites generated by LAB. Mixed fermentations involving P. taetrolens LMG 2336 and Lactobacillus casei CECT 475 were cultivated, entrapping both microorganisms alternately. Alginate, alginate/starch and carboxymethyl cellulose/k-carrageenan were tested as encapsulating agents. The immobilization of L. casei in 2% alginate/2% starch beads was found to be the best strategy, improving the production of lactobionic acid by 182% with respect to co-cultures with free cells. This study proves the potential of LAB encapsulation for the protection of sensitive strains in mixed food fermentations.

Similar content being viewed by others

References

Alonso S, Rendueles M, Díaz M (2015) A novel approach to monitor stress-induced physiological responses in immobilized microorganisms. Appl Microbiol Biotechnol 99:3573–3583

Champagne CP, Fustier P (2007) Microencapsulation for the improved delivery of bioactive compounds into foods. Curr Opin Biotechnol 18:184–190

Sathyabama S, Ranjith Kumar M, Bruntha Devi P, Vijayabharathi R, Brindha Priyadharisini V (2014) Co-encapsulation of probiotics with prebiotics on alginate matrix and its effect on viability in simulated gastric environment. LWT Food Sci Technol 57:419–425

Chávarri M, Marañón I, Ares R, Ibáñez FC, Marzo F, Villarán MC (2010) Microencapsulation of a probiotic and prebiotic in alginate-chitosan capsules improves survival in simulated gastro-intestinal conditions. Int J Food Microbiol 142:185–189

Divyashri G, Prapulla SG (2015) Mass transfer characterization of gamma-aminobutyric acid production by Enterococcus faecium CFR 3003: encapsulation improves its survival under simulated gastro-intestinal conditions. Bioprocess Biosyst Eng 38:569–574

Martin MJ, Lara-Villoslada F, Ruiz MA, Morales ME (2013) Effect of unmodified starch on viability of alginate-encapsulated Lactobacillus fermentum CECT5716. LWT Food Sci Technol 53:480–486

Lozano-Vazquez G, Lobato-Calleros C, Escalona-Buendia H, Chavez G, Alvarez-Ramirez J, Vernon-Carter EJ (2015) Effect of the weight ratio of alginate-modified tapioca starch on the physicochemical properties and release kinetics of chlorogenic acid containing beads. Food Hydrocoll 48:301–311

Dafe A, Etemadi H, Zarredar H, Mahdavinia GR (2017) Development of novel carboxymethyl cellulose/k-carrageenan blends as an enteric delivery vehicle for probiotic bacteria. Int J Biol Macromol 97:299–307

Hambleton A, Fabra MJ, Debeaufort F, Dury-Brun C, Voilley A (2009) Interface and aroma barrier properties of iota-carrageenan emulsion-based films used for encapsulation of active food compounds. J Food Eng 93:80–88

Cheirsilp B, Shoji H, Shimizu H, Shioya S (2003) Interactions between Lactobacillus kefiranofaciens and Saccharomyces cerevisiae in mixed culture for kefiran production. J Biosci Bioeng 96:279–284

Doleyres Y, Fliss I, Lacroix C (2004) Increased stress tolerance of Bifidobacterium longum and Lactococcus lactis produced during continuous mixed-strain immobilized-cell fermentation. J Appl Microbiol 97:527–539

Grattepanche F, Audet P, Lacroix C (2007) Enhancement of functional characteristics of mixed lactic culture producing nisin Z and exopolysaccharides during continuous prefermentation of milk with immobilized cells. J Dairy Sci 90:5361–5373

Smid EJ, Lacroix C (2013) Microbe-microbe interactions in mixed culture food fermentations. Curr Opin Biotechnol 24:148–154

Simova E, Beshkova D, Angelov A, Hristozova TS, Frengova G, Spasov Z (2002) Lactic acid bacteria and yeasts in kefir grains and kefir made from them. J Ind Microbiol Biotechnol 28:1–6

Digaitiene A, Hansen ÅS, Juodeikiene G, Eidukonyte D, Josephsen J (2012) Lactic acid bacteria isolated from rye sourdoughs produce bacteriocin-like inhibitory substances active against Bacillus subtilis and fungi. J Appl Microbiol 112:732–742

García C, Rendueles M, Díaz M (2019) Liquid-phase food fermentations with microbial consortia involving lactic acid bacteria: a review. Food Res Int 119:207–220

Adebola OO, Corcoran O, Morgan WA (2014) Synbiotics: the impact of potential prebiotics inulin, lactulose and lactobionic acid on the survival and growth of lactobacilli probiotics. J Funct Foods 10:75–84

Gutiérrez LF, Hamoudi S, Belkacemi K (2012) Lactobionic acid: a high value-added lactose derivative for food and pharmaceutical applications. Int Dairy J 26:103–111

Alonso S, Rendueles M, Díaz M (2011) Efficient lactobionic acid production from whey by Pseudomonas taetrolens under pH-shift conditions. Bioresour Technol 102:9730–9736

Alonso S, Rendueles M, Díaz M (2012) Role of dissolved oxygen availability on lactobionic acid production from whey by Pseudomonas taetrolens. Bioresour Technol 109:140–147

Alonso S, Rendueles M, Díaz M (2013) Selection method of pH conditions to establish Pseudomonas taetrolens physiological states and lactobionic acid production. Appl Microbiol Biotechnol 97:3843–3854

García C, Rendueles M, Díaz M (2017) Microbial amensalism in Lactobacillus casei and Pseudomonas taetrolens mixed culture. Bioprocess Biosyst Eng 40:1111–1122

Yousseef M, Lafarge C, Valentin D, Lubbers S, Husson F (2016) Fermentation of cow milk and/or pea milk mixtures by different starter cultures: physico-chemical and sensorial properties. LWT Food Sci Technol 69:430–437

Sultana K, Godward G, Reynolds N, Arumugaswamy R, Peiris P, Kailasapathy K (2000) Encapsulation of probiotic bacteria with alginate-starch and evaluation of survival in simulated gastrointestinal conditions and in yoghurt. Int J Food Microbiol 62:47–55

López-Córdoba A, Deladino L, Martino M (2013) Effect of starch filler on calcium-alginate hydrogels loaded with yerba mate antioxidants. Carbohydr Polym 95:315–323

Sandoval-Castilla O, Lobato-Calleros C, García-Galindo HS, Alvarez-Ramírez J, Vernon-Carter EJ (2010) Textural properties of alginate-pectin beads and survivability of entrapped Lb. casei in simulated gastrointestinal conditions and in yoghurt. Food Res Int 43:111–117

Chou S, Luo L, Lai J, Ma DH (2016) On the importance of Bloom number of gelatin to the development of biodegradable in situ gelling copolymers for intracameral drug delivery. Int J Pharm 511:30–43

Saxena A, Sachin K, Bohidar HB, Verma AK (2005) Effect of molecular weight heterogeneity on drug encapsulation efficiency of gelatin nano-particles. Colloids Surf B Biointerfaces 45:42–48

Heidebach T, Först P, Kulozik U (2012) Microencapsulation of probiotic cells for food applications. Crit Rev Food Sci Nutr 52:291–311

Hosseini SM, Hosseini H, Mohammadifar MA, German JB, Mortazavian AM, Mohammadi A, Khosravi-Darani K, Shojaee-Aliabadi S, Khaksar R (2014) Preparation and characterization of alginate and alginate-resistant starch microparticles containing nisin. Carbohydr Polym 103:573–580

Rathore S, Desai PM, Liew CV, Chan LW, Heng PWS (2013) Microencapsulation of microbial cells. J Food Eng 116:369–381

Krasaekoopt W, Bhandari B, Deeth H (2003) Evaluation of encapsulation techniques of probiotics for yoghurt. Int Dairy J 13:3–13

Baldwin C, Akashe A, Zeller AL, Márquez-Sánchez M (2007) Mineral complexes of lactobionic acid and method of using for mineral fortification of food products. United States Patent Application Pub. No.: US 2007/0026110A1.

Paşcalău V, Popescu V, Popescu GL, Dudescu MC, Borodi G, Dinescu A, Perhaiţa I, Paul M (2012) The alginate/k-carrageenan ratio’s influence on the properties of the cross-linked composite films. J Alloy Compd 536:418–423

Mooranian A, Negrulj R, Al-Sallami HS, Fang Z, Mikov M, Golocorbin-Kon S, Fakhoury M, Arfuso F, Al-Salami H (2015) Release and swelling studies of an innovative antidiabetic-bile acid microencapsulated formulation, as a novel targeted therapy for diabetes treatment. J Microencapsul 32:151–216

Abdel-Rahman MA, Tashiro Y, Sonomoto K (2013) Recent advances in lactic acid production by microbial fermentation processes. Biotechnol Adv 31:877–902

Genisheva Z, Mussatto SI, Oliveira JM, Teixeira JA (2013) Malolactic fermentation of wines with immobilized lactic acid bacteria—influence of concentration, type of support material and storage conditions. Food Chem 138:1510–1514

Zhao Z, Xie X, Wang Z, Tao Y, Niu X, Huang X, Liu L, Li Z (2016) Immobilization of Lactobacillus rhamnosus in mesoporous silica-based material: an efficiency continuous cell-recycle fermentation system for lactic acid production. J Biosci Bioeng 121:645–651

Zhang Z, Zhang R, Chen L, McClements DJ (2016) Encapsulation of lactase (β-galactosidase) into k-carrageenan-based hydrogel beads: impact of environmental conditions on enzyme activity. Food Chem 200:69–75

Zwietering MH, Jongenburger I, Rombouts FM, van’T Riet K (1990) Modelling of the bacterial growth curve. Appl Environ Microbiol 56:1875–1881

Wallenius J, Uuksulainen T, Salonen K, Rautio J, Eerikäinen T (2011) The effect of temperature and pH gradients on Lactobacillus rhamnosus gene expression of stress-related genes. Bioprocess Biosyst Eng 34:1169–1176

Wu C, Zhang J, Wang M, Du G, Chen J (2012) Lactobacillus casei combats acid stress by maintaining cell membrane functionality. J Ind Microbiol Biotechnol 39:1031–1039

Acknowledgements

Authors thank the financial support from the Government of the Principality of Asturias by the project FC-GRUPIN-IDI/2018/000127. Authors also wish to thank the technical assistance of Marta Alonso (Process Image Area, Scientific-Technical Services, University of Oviedo).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

García, C., Ranieri, G., Rendueles, M. et al. Exploring encapsulation strategies as a protective mechanism to avoid amensalism in mixed populations of Pseudomonas taetrolens and Lactobacillus casei. Bioprocess Biosyst Eng 43, 55–66 (2020). https://doi.org/10.1007/s00449-019-02204-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-019-02204-8