Abstract

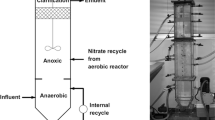

Biological reduction of sulphate at low hydraulic retention time (HRT) is presented in this paper. A sulphidogenic inverse fluidized-bed bioreactor (IFBB) was operated successfully at a progressively decreasing HRT from 1 to 0.125 days for a total of 155 days. Synthetic wastewater containing sulphate at a concentration of 745 (± 17) mg/L was used. COD was supplied as lactate in variable concentrations at COD/SO42− ratios of 1.2–2.4. The pH of the feed ranged between 5.2 and 6.2. The highest measured removal rates were 2646 and 4866 mg SO42−/L day at an HRT of 0.25 and 0.125 days, respectively, using a COD/SO42− ratio of 2.3. The biological sulphate reduction was limited by the influent COD concentrations at a COD/SO42− ratio < 2.3. The IFBB ensured biomass retention at a maximum liquid residence time of θ = 3.84 (± 0.013), according to the residence time distribution analysis. Hydrodynamic studies were carried out at recirculation rates of 0, 200, 300, 350, 400, and 500 L/h to measure the relative bed expansion, the mixing pattern, and the fluidization characteristics of the reactor. A dynamic model is also developed based on COD and sulphate as the two limiting substrates in a Monod-type kinetic equation describing the kinetics of lactate oxidation by SRB. A set of the following parameters \(Y_{{{\text{VSS}}/{\text{COD}}}}^{\prime }\) = 0.23 mg COD of VSS/mg lactate, µmax = 1.758 day− 1, KCOD = 956 mg COD of lactate/L, \({K_{{\text{S}}{{\text{O}}_{\text{4}}}}}\) = 316 mg SO42−/L, kd = 0.024 day− 1, tres = 5.7 days, and kexchange = 0.4 day− 1 simulated adequately the residual effluent COD and sulphate concentrations, the produced sulphide concentration as well as the pH of the IFBB effluent. Low HRT values, shown efficient in this study, are prerequisite for industrial applicability and economic feasibility of the sulphur reduction process. In addition, the developed model can be used for optimum experimental design and further process upscale and development.

Similar content being viewed by others

References

Monterroso C, Macías F (1998) Drainage waters affected by pyrite oxidation in a coal mine in Galicia (NW Spain): composition and mineral stability. Sci Total Environ 216:121–132

Bai H, Kang Y, Quan H, Han Y, Sun J, Feng Y (2013) Treatment of acid mine drainage by sulfate reducing bacteria with iron in bench scale runs. Bioresour Technol 128:818–822

Sarmiento AM, Olías M, Nieto JM, Cánovas CR, Delgado J (2009) Natural attenuation processes in two water reservoirs receiving acid mine drainage. Sci Total Environ 407:2051–2062

Mapanda F, Nyamadzawo G, Nyamangara J, Wuta M (2007) Effects of discharging acid-mine drainage into evaporation ponds lined with clay on chemical quality of the surrounding soil and water. Phys Chem Earth Parts A/B/C 32:1366–1375

Cheung NS, Peng ZF, Chen MJ, Moore PK, Whiteman M (2007) Hydrogen sulfide induced neuronal death occurs via glutamate receptor and is associated with calpain activation and lysosomal rupture in mouse primary cortical neurons. Neuropharmacology 53:505–514

Jachuck RJ, Lee J, Kolokotsa D, Ramshaw C, Valachis P, Yanniotis S (1997) Process intensification for energy saving. Appl Therm Eng 17:861–867

Villa-Gomez D, Ababneh H, Papirio S, Rousseau DPL, Lens PNL (2011) Effect of sulfide concentration on the location of the metal precipitates in inversed fluidized bed reactors. J Hazard Mater 192:200–207

Prato-Garcia D, Cervantes FJ, Buitrón G (2013) Azo dye decolorization assisted by chemical and biogenic sulfide. J Hazard Mater 250:462–468

Renganathan T, Krishnaiah K (2004) Liquid phase mixing in 2-phase liquid–solid inverse fluidized bed. Chem Eng J 98:213–218

Buffière P, Moletta R (1999) Some hydrodynamic characteristics of inverse three phase fluidized-bed reactors. Chem Eng Sci 54:1233–1242

Comte MP, Bastoul D, Hebrard G, Roustan M, Lazarova V (1997) Hydrodynamics of a three-phase fluidized bed-the inverse turbulent bed. Chem Eng Sci 52:3971–3977

Rajasimman M, Karthikeyan C (2007) Aerobic digestion of starch wastewater in a fluidized bed bioreactor with low density biomass support. J Hazard Mater 143:82–86

Garcia-Calderon D, Buffiere P, Moletta R, Elmaleh S (1998) Anaerobic digestion of wine distillery wastewater in down-flow fluidized bed. Water Res 32:3593–3600

Alvarado-Lassman A, Rustrián E, García-Alvarado MA, Rodríguez-Jiménez GC, Houbron E (2008) Brewery wastewater treatment using anaerobic inverse fluidized bed reactors. Bioresour Technol 99:3009–3015

Alvarado-Lassman A, Rustrian E, Garcia-Alvarado MA, Houbron E (2006) Simultaneous removal of carbon and nitrogen in an anaerobic inverse fluidized bed reactor. Water Sci Technol 54:111–117

Kijjanapanich P, Do AT, Annachhatre AP, Esposito G, Yeh DH, Lens PNL (2014) Biological sulfate removal from construction and demolition debris leachate: effect of bioreactor configuration. J Hazard Mater 269:38–44

Reyes-Alvarado LC, Okpalanze NN, Kankanala D, Rene ER, Esposito G, Lens PNL (2017) Forecasting the effect of feast and famine conditions on biological sulphate reduction in an anaerobic inverse fluidized bed reactor using artificial neural networks. Process Biochem 55:146–161

Reyes-Alvarado LC, Rene ER, Esposito G, Lens PNL (2018) In: Varjani SJ, Gnansounou E, Gurunathan B, Pant D, Zakaria ZA (eds) Bioprocesses for sulphate removal from wastewater. Waste Bioremediation Springer Singapore, Singapore

Rice EW (2012) Standard methods for examination of water and wastewater, 22nd edn. American Water Works Association, Washington, DC

Fogler HS (2006) Elements of chemical reaction engineering, 4th edn. Pearson Education International, Upper Saddle River

Wang J, Shi M, Lu H, Wu D, Shao M-F, Zhang T, Ekama GA, van Loosdrecht MCM, Chen G-H (2011) Microbial community of sulfate-reducing up-flow sludge bed in the SANI® process for saline sewage treatment. Appl Microbiol Biotechnol 90:2015

Oude Elferink SJWH, Vorstman WJC, Sopjes A, Stams AJM (1998) Characterization of the sulfate-reducing and syntrophic population in granular sludge from a full-scale anaerobic reactor treating papermill wastewater. FEMS Microbiol Ecol 27:185–194

Cresson R, Escudié R, Steyer J-P, Delgenès J-P, Bernet N (2008) Competition between planktonic and fixed microorganisms during the start-up of methanogenic biofilm reactors. Water Res 42:792–800

Escudié R, Cresson R, Delgenès J-P, Bernet N (2011) Control of start-up and operation of anaerobic biofilm reactors: an overview of 15 years of research. Water Res 45:1–10

Martin AD (2000) Interpretation of residence time distribution data. Chem Eng Sci 55:5907–5917

Marsili-Libelli S (2016) Environmental systems analysis with MATLAB, 1st edn. CRC Press, London

Tangirala A (2014) Principles of system identification, 1st edn. CRC Press, London

Sánchez O, Michaud S, Escudié R, Delgenès J-P, Bernet N (2005) Liquid mixing and gas–liquid mass transfer in a three-phase inverse turbulent bed reactor. Chem Eng J 114:1–7

Brannock MWD, Wang Y, Leslie G (2010) Evaluation of full-scale membrane bioreactor mixing performance and the effect of membrane configuration. J Membr Sci 350:101–108

Neves L, Oliveira R, Alves MM (2004) Influence of inoculum activity on the bio-methanization of a kitchen waste under different waste/inoculum ratios. Process Biochem 39:2019–2024

Velasco A, Ramírez M, Volke-Sepúlveda T, González-Sánchez A, Revah S (2008) Evaluation of feed COD/sulfate ratio as a control criterion for the biological hydrogen sulfide production and lead precipitation. J Hazard Mater 151:407–413

Ghigliazza R, Lodi A, Rovatti M (2000) Kinetic and process considerations on biological reduction of soluble and scarcely soluble sulfates. Res Conserv Recycl 29:181–194

Papirio S, Esposito G, Pirozzi F (2013) Biological inverse fluidized-bed reactors for the treatment of low pH- and sulphate-containing wastewaters under different COD conditions. Environ Technol 34:1141–1149

Kaksonen AH, Puhakka JA (2007) Sulfate reduction based bioprocesses for the treatment of acid mine drainage and the recovery of metals. Eng Life Sci 7:541–564

Okabe S, Nielsen PH, Charcklis WG (1992) Factors affecting microbial sulfate reduction by Desulfovibrio desulfuricans in continuous culture: limiting nutrients and sulfide concentration. Biotechnol Bioeng 40:725–734

Celis-Garcia LB, Razo-Flores E, Monroy O (2007) Performance of a down-flow fluidized bed reactor under sulfate reduction conditions using volatile fatty acids as electron donors. Biotechnol Bioeng 97:771–779

Kaksonen AH, Franzmann PD, Puhakka JA (2004) Effects of hydraulic retention time and sulfide toxicity on ethanol and acetate oxidation in sulfate-reducing metal-precipitating fluidized-bed reactor. Biotechnol Bioeng 86:332–343

Rittmann BE, McCarty PL (2001) Environmental biotechnology:principles and applications. McGraw-Hill, Boston

Dar SA, Kleerebezem R, Stams AJM, Kuenen JG, Muyzer G (2008) Competition and coexistence of sulfate-reducing bacteria, acetogens and methanogens in a lab-scale anaerobic bioreactor as affected by changing substrate to sulfate ratio. Appl Microbiol Biotechnol 78:1045–1055

Traore AS, Gaudin C, Hatchikian CE, Le Gall J, Belaich JP (1983) Energetics of growth of a defined mixed culture of Desulfovibrio vulgaris and Methanosarcina barkeri: maintenance energy coefficient of the sulfate-reducing organism in the absence and presence of its partner. J Bacteriol 155:1260–1264

Sahinkaya E, Gungor M (2010) Comparison of sulfidogenic up-flow and down-flow fluidized-bed reactors for the biotreatment of acidic metal-containing wastewater. Bioresour Technol 101:9508–9514

Bayrakdar A, Sahinkaya E, Gungor M, Uyanik S, Atasoy AD (2009) Performance of sulfidogenic anaerobic baffled reactor (ABR) treating acidic and zinc-containing wastewater. Bioresour Technol 100:4354–4360

Poinapen J, Ekama G, Wentzel M (2009) Biological sulphate reduction with primary sewage sludge in an upflow anaerobic sludge bed (UASB) reactor—part 2: modification of simple wet chemistry analytical procedures to achieve COD and S mass balances. Water SA 35:535–542

Barton LL (1995) Sulfate-reducing bacteria. Plenum, New York

Kaksonen AH, Riekkola-Vanhanen ML, Puhakka JA (2003) Optimization of metal sulphide precipitation in fluidized-bed treatment of acidic wastewater. Water Res 37:255–266

Acknowledgements

This research was funded by the European Union through the Erasmus Mundus Joint Doctorate Programme ETeCoS3 (Environmental Technologies for Contaminated Solids, Soils and Sediments, grant agreement FPA no. 2010-0009). The authors thank the staff members from the laboratory of UNESCO-IHE (Delft, the Netherlands) for analytical support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Reyes-Alvarado, L.C., Hatzikioseyian, A., Rene, E.R. et al. Hydrodynamics and mathematical modelling in a low HRT inverse fluidized-bed reactor for biological sulphate reduction. Bioprocess Biosyst Eng 41, 1869–1882 (2018). https://doi.org/10.1007/s00449-018-2008-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-018-2008-y