Abstract

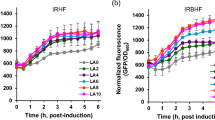

The lycopene biosynthetic genes crtE, crtB, and crtI from Deinococcus wulumuqiensis R12 were integrated into three different vector backbones—pET28a, pTrc99A, and pUC18—and the resulting recombinant plasmids pET28a-EBI, pTrc99A-EBI, and pUC18-EBI were introduced into different Escherichia coli hosts. The results showed that lycopene production of strain 28BL was lower than that of 99 series strains without IPTG in LB medium. In addition, lycopene production of 99JM with supplementation of 20% (w/v) glycerol was 1.6-fold higher than with supplementation of 6% (w/v) glucose. After optimization of the host strain and culture medium, the yield of microbial lycopene was increased successfully. When recombinant E. coli 99DH was cultivated under exposure to light in 2YT + Gly medium, the highest lycopene production rate was 26.2 mg/L/h at 30 h, and the maximum specific lycopene content was 67 mg/g dry cell (925 mg/L) at 40 h, which represents a 76% increase over the starting point.

Similar content being viewed by others

References

Di Mascio P, Kaiser S, Sies H (1989) Lycopene as the most efficient biological carotenoid singlet oxygen quencher. Arch Biochem Biophys 274:532–538

Kong KW, Khoo HE, Prasad KN, Ismail A, Tan CP, Rajab NF (2010) Revealing the power of the natural red pigment lycopene. Molecules 15:959–987

Matos HR, Capelozzi VL, Gomes OF, Di Mascio P, Medeiros MH (2001) Lycopene inhibits DNA damage and liver necrosis in rats treated with ferric nitrilotriacetate. Arch Biochem Biophys 396:171–177

Story EN, Kopec RE, Schwartz SJ, Harris GK (2010) An update on the health effects of tomato lycopene. Annu Rev Food Sci Technol 1:189–210

Liu XJ, Liu RS, Li HM, Tang YJ (2012) Lycopene production from synthetic medium by Blakeslea trispora NRRL 2895 (+) and 2896 (−) in a stirred-tank fermenter. Bioprocess Biosyst Eng 35:739–749

Hundle B, Alberti M, Nievelstein V, Beyer P, Kleinig H, Armstrong G, Burke D, Hearst J (1994) Functional assignment of Erwinia herbicola Eho10 carotenoid genes expressed in Escherichia coli. Mol Gen Genet MGG 245:406–416

Verwaal R, Wang J, Meijnen J-P, Visser H, Sandmann G, van den Berg JA, van Ooyen AJ (2007) High-level production of beta-carotene in Saccharomyces cerevisiae by successive transformation with carotenogenic genes from Xanthophyllomyces dendrorhous. Appl Environ Microbiol 73:4342–4350

Qiang W, Ling-ran F, Luo W, Han-guang L, Lin W, Ya Z, Xiao-bin Y (2014) Mutation breeding of lycopene-producing strain Blakeslea trispora by a novel atmospheric and room temperature plasma (ARTP). Appl Biochem Biotechnol 174:452–460

Emadi H, Amaninejad P, Emtiazjoo M, Sahhafi HH (2010) Effects of Dunaliella microalgae (Dunaliellasalina) on different levels of complement C3, C4 and antioxidant capacity in rainbow trout (Oncorhynchusmykiss). Adv Environ Biol 4:456–464

Wang J-F, Liu X-J, Liu R-S, Li H-M, Tang Y-J (2012) Optimization of the mated fermentation process for the production of lycopene by Blakeslea trispora NRRL 2895 (+) and NRRL 2896 (−). Bioprocess Biosyst Eng 35:553–564

Liu Q, Zhu L, Wang Y, Li D, Wan D, Tang Y (2009) Advance on the production of lycopene by microbial fermentation. Food Ferment Ind 35:157–161

Moise AR, Al-Babili S, Wurtzel ET (2014) Mechanistic aspects of carotenoid biosynthesis. Chem Rev 114:164–193

Zhao J, Li Q, Sun T, Zhu X, Xu H, Tang J, Zhang X, Ma Y (2013) Engineering central metabolic modules of Escherichia coli for improving beta-carotene production. Metab Eng 17:42–50

Ramos KRM, Valdehuesa KNG, Liu H, Nisola GM, Lee W-K, Chung W-J (2014) Combining De Ley–Doudoroff and methylerythritol phosphate pathways for enhanced isoprene biosynthesis from d-galactose. Bioprocess Biosyst Eng 37:2505–2513

Das A, Yoon S-H, Lee S-H, Kim J-Y, Oh D-K, Kim S-W (2007) An update on microbial carotenoid production: application of recent metabolic engineering tools. Appl Microbiol Biotechnol 77:505

Sun T, Miao L, Li Q, Dai G, Lu F, Liu T, Zhang X, Ma Y (2014) Production of lycopene by metabolically-engineered Escherichia coli. Biotechnol Lett 36:1515–1522

Yoon SH, Lee YM, Kim JE, Lee SH, Lee JH, Kim JY, Jung KH, Shin YC, Keasling JD, Kim SW (2006) Enhanced lycopene production in Escherichia coli engineered to synthesize isopentenyl diphosphate and dimethylallyl diphosphate from mevalonate. Biotechnol Bioeng 94:1025–1032

Kim YS, Lee JH, Kim NH, Yeom SJ, Kim SW, Oh DK (2011) Increase of lycopene production by supplementing auxiliary carbon sources in metabolically engineered Escherichia coli. Appl Microbiol Biotechnol 90:489–497

Zhang T-C, Li W, Luo X-G, Feng C-X, Zhang M-H, Du W, Ma D-Y (2015) Increase of the lycopene production in the recombinant strains of Escherichia coli by supplementing with fructose. Adv Appl Biotechnol 332, pp 29–35

Zhu F, Lu L, Fu S, Zhong X, Hu M, Deng Z, Liu T (2015) Targeted engineering and scale up of lycopene overproduction in Escherichia coli. Process Biochem 50:341–346

Chen Y-Y, Shen H-J, Cui Y-Y, Chen S-G, Weng Z-M, Zhao M, Liu J-Z (2013) Chromosomal evolution of Escherichia coli for the efficient production of lycopene. BMC Biotechnol 13:1

Yang J, Guo L (2014) Biosynthesis of β-carotene in engineered E. coli using the MEP and MVA pathways. Microb Cell Fact 13:160

Yoon SH, Kim JE, Lee SH, Park HM, Choi MS, Kim JY, Lee SH, Shin YC, Keasling JD, Kim SW (2007) Engineering the lycopene synthetic pathway in E. coli by comparison of the carotenoid genes of Pantoea agglomerans and Pantoea ananatis. Appl Microbiol Biotechnol 74:131–139

Nishizaki T, Tsuge K, Itaya M, Doi N, Yanagawa H (2007) Metabolic engineering of carotenoid biosynthesis in Escherichia coli by ordered gene assembly in Bacillus subtilis. Appl Environ Microbiol 73:1355–1361

Lim HN, Lee Y, Hussein R (2011) Fundamental relationship between operon organization and gene expression. In: Proceedings of the National Academy of Sciences vol 108, pp 10626–10631

Zhang S, Zhao X, Tao Y, Lou C (2015) A novel approach for metabolic pathway optimization: Oligo-linker mediated assembly (OLMA) method. J Biol Eng 9:23

Wang Z, Jin L, Yuan Z, Węgrzyn G, Węgrzyn A (2009) Classification of plasmid vectors using replication origin, selection marker and promoter as criteria. Plasmid 61:47–51

Friehs K (2004) Plasmid copy number and plasmid stability. New trends and developments in biochemical engineering. Springer, Berlin, Heidelberg

Nacken V, Achstetter T, Degryse E (1996) Probing the limits of expression levels by varying promoter strength and plasmid copy number in Saccharomyces cerevisiae. Gene 175:253–260

Kim SW, Kim JB, Ryu JM, Jung JK, Kim JH (2009) High-level production of lycopene in metabolically engineered E. coli. Process Biochem 44:899–905

Cranenburgh RM, Lewis KS, Hanak JA (2004) Effect of plasmid copy number and lac operator sequence on antibiotic-free plasmid selection by operator-repressor titration in Escherichia coli. J Mol Microbiol Biotechnol 7:197–203

Chakravartty V, Cronan JE (2015) A series of medium and high copy number arabinose-inducible Escherichia coli expression vectors compatible with pBR322 and pACYC184. Plasmid 81:21–26

Jin W, Xu X, Jiang L, Zhang Z, Li S, Huang H (2015) Putative carotenoid genes expressed under the regulation of Shine-Dalgarno regions in Escherichia coli for efficient lycopene production. Biotechnol Lett 37:2303–2310

Tao L, Jackson RE, Rouvière PE, Cheng Q (2005) Isolation of chromosomal mutations that affect carotenoid production in Escherichia coli: mutations alter copy number of ColE1-type plasmids. FEMS Microbiol Lett 243:227–233

Ryan W, Parulekar SJ (1991) Recombinant protein synthesis and plasmid instability in continuous cultures of Escherichia coli JM103 harboring a high copy number plasmid. Biotechnol Bioeng 37:415–429

Pushnova EA, Geier M, Zhu YS (2000) An easy and accurate agarose gel assay for quantitation of bacterial plasmid copy numbers. Anal Biochem 284:70–76

Silva F, Queiroz JA, Domingues FC (2012) Evaluating metabolic stress and plasmid stability in plasmid DNA production by Escherichia coli. Biotechnol Adv 30:691–708

Kramer MG (2016) Determination of plasmid segregational stability in a growing bacterial population. Bact Ther Cancer Methods Protoc 1409:125–133

Karim AS, Curran KA, Alper HS (2013) Characterization of plasmid burden and copy number in Saccharomyces cerevisiae for optimization of metabolic engineering applications. FEMS Yeast Res 13:107–116

Gruber DF, Pieribone VA, Porton B, Kao H-T (2008) Strict regulation of gene expression from a high-copy plasmid utilizing a dual vector system. Protein Expr Purif 60:53–57

Thakker C, Zhu J, San K-Y, Bennett G (2011) Heterologous pyc gene expression under various natural and engineered promoters in Escherichia coli for improved succinate production. J Biotechnol 155:236–243

Martin VJ, Pitera DJ, Withers ST, Newman JD, Keasling JD (2003) Engineering a mevalonate pathway in Escherichia coli for production of terpenoids. Nature Biotechnol 21:796–802

Jones KL, Kim S-W, Keasling J (2000) Low-copy plasmids can perform as well as or better than high-copy plasmids for metabolic engineering of bacteria. Metab Eng 2:328–338

Wang Z, Xiang L, Shao J, Węgrzyn A, Węgrzyn G (2006) Effects of the presence of ColE1 plasmid DNA in Escherichia coli on the host cell metabolism. Microb Cell Fact 5:34

Yoon S-H, Lee S-H, Das A, Ryu H-K, Jang H-J, Kim J-Y, Oh D-K, Keasling JD, Kim S-W (2009) Combinatorial expression of bacterial whole mevalonate pathway for the production of β-carotene in E. coli. J Biotechnol 140:218–226

Lee PC, Mijts BN, Schmidt-Dannert C (2004) Investigation of factors influencing production of the monocyclic carotenoid torulene in metabolically engineered Escherichia coli. Appl Microbiol Biotechnol 65:538–546

Shi J, Dai Y, Kakuda Y, Mittal G, Xue SJ (2008) Effect of heating and exposure to light on the stability of lycopene in tomato puree. Food Control 19:514–520

Giannakis S, Rtimi S, Darakas E, Escalas-Cañellas A, Pulgarin C (2015) Light wavelength-dependent E. coli survival changes after simulated solar disinfection of secondary effluent. Photochem Photobiol Sci 14:2238–2250

Murmu J, Chinthapalli B, Raghavendra AS (2003) Light activation of NADP malic enzyme in leaves of maize: marginal increase in activity, but marked change in regulatory properties of enzyme. J Plant Physiol 160:51–56

Ruiz-Hidalgo M, Benito E, Sandmann G, Eslava A (1997) The phytoene dehydrogenase gene of Phycomyces: regulation of its expression by blue light and vitamin A. Mol Gen Genet MGG 253:734–744

Acknowledgements

This work was supported by the Joint Fund of the National Natural Science Foundation of China (U1603112), the National Natural Science Foundation of China for Young Scholars (21406111), and the Program for Innovative Research Team in Universities of Jiangsu Province (2015).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Research involving human participants and/or animals

This study does not contain any experiments involving human subjects or experimental animals.

Conflict of interest

The authors declare no conflicts of interest.

Rights and permissions

About this article

Cite this article

Xu, J., Xu, X., Xu, Q. et al. Efficient production of lycopene by engineered E. coli strains harboring different types of plasmids. Bioprocess Biosyst Eng 41, 489–499 (2018). https://doi.org/10.1007/s00449-017-1883-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-017-1883-y