Abstract

The production of exo-polygalacturonase (exo-PG) from orange peel (OP), a food industrial waste, using Aspergillus sojae was studied in submerged culture. A simple, low-cost, industrially significant medium formulation, composed of only OP and (NH4)2SO4 (AS) was developed. At an inoculum size of 2.8 × 103 spores/mL, growth was in the form of pellets, which provided better mixing of the culture broth and higher exo-PG activity. These pellets were successfully used as an inoculum for bioreactors and 173.0 U/mL exo-PG was produced. Fed-batch cultivation further enhanced the exo-PG activity to 244.0 U/mL in 127.5 h. The final morphology in the form of pellets is significant to industrial fermentation easing the subsequent downstream processing. Furthermore, the low pH trend obtained during this fermentation serves an advantage to fungal fermentations prone to contamination problems. As a result, an economical exo-PG production process was defined utilizing a food industrial by-product and producing high amount of enzyme.

Similar content being viewed by others

References

Marin FR, Soler-Rivas C, Benavente-Garcia O, Castillo J, Perez-Alvarez JA (2007) By-products from different citrus processes as a source of customized functional fibres. Food Chem 100:736–741

Lopez JAS, Li Q, Thompson IP (2010) Biorefinery of waste orange peel. Crit Rev Biotechnol 30:63–69

Mamma D, Kourtoglou E, Christakopoulos P (2008) Fungal multienzyme production on industrial by-products of the citrus-processing industry. Bioresour Technol 99:2373–2383

Giese EC, Dekker RFH, Barbosa AM (2008) Orange bagasse as substrate for the production of pectinase and laccase by Botryosphaeria rhodina MAMB-05 in submerged and solid state fermentation. Bioresources 3:335–345

El-Sheekh MM, Ismail AMS, El-Abd MA, Hegazy EM, El-Diwany AI (2009) Effective technological pectinases by Aspergillus carneus NRC1 utilizing the Egyptian orange juice industry scraps. Int Biodeterior Biodegrad 63:12–18

Tao NG, Shi WQ, Liu YJ, Huang SR (2011) Production of feed enzymes from citrus processing waste by solid-state fermentation with Eupenicillium javanicum. Int J Food Sci Technol 46:1073–1079

Heerd D, Yegin S, Tari C, Fernandez-Lahore M (2012) Pectinase enzyme-complex production by Aspergillus spp. in solid-state fermentation: a comparative study. Food Bioprod Process 90:102–110

Buyukkileci AO, Tari C, Fernandez-Lahore M (2011) Enhanced production of exo-polygalacturonase from agro-based products by Aspergillus sojae. Bioresources 6:3452–3468

Oberoi HS, Vadlani PV, Nanjundaswamy A, Bansal S, Singh S, Kaur S, Babbar N (2011) Enhanced ethanol production from Kinnow mandarin (Citrus reticulata) waste via a statistically optimized simultaneous saccharification and fermentation process. Bioresour Technol 102:1593–1601

Pourbafrani M, Forgacs G, Horvath IS, Niklasson C, Taherzadeh MJ (2010) Production of biofuels, limonene and pectin from citrus wastes. Bioresour Technol 101:4246–4250

Wilkins MR, Widmer WW, Grohmann K (2007) Simultaneous saccharification and fermentation of citrus peel waste by Saccharomyces cerevisiae to produce ethanol. Process Biochem 42:1614–1619

Wilkins MR, Widmer WW, Grohmann K, Cameron RG (2007) Hydrolysis of grapefruit peel waste with cellulase and pectinase enzymes. Bioresour Technol 98:1596–1601

Fontana RC, Polidoro TA, da Silveira MM (2009) Comparison of stirred tank and airlift bioreactors in the production of polygalacturonases by Aspergillus oryzae. Bioresour Technol 100:4493–4498

Kashyap DR, Vohra PK, Chopra S, Tewari R (2001) Applications of pectinases in the commercial sector: a review. Bioresour Technol 77:215–227

Ribeiro DS, Henrique SMB, Oliveira LS, Macedo GA, Fleuri LF (2010) Enzymes in juice processing: a review. Int J Food Sci Tech 45:635–641

Jayani RS, Saxena S, Gupta R (2005) Microbial pectinolytic enzymes: a review. Process Biochem 40:2931–2944

Favela-Torres E, Volke-Sepulveda T, Viniegra-Gonzalez G (2006) Production of hydrolytic depolymerising pectinases. Food Technol Biotechnol 44:221–227

Zeni J, Cence K, Grando CE, Tiggermann L, Colet R, Lerin LA, Cansian RL, Toniazzo G, de Oliveira D, Valduga E (2011) Screening of pectinase-producing microorganisms with polygalacturonase activity. Appl Biochem Biotechnol 163:383–392

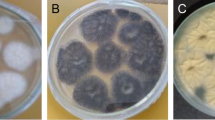

Gogus N, Tari C, Oncu S, Unluturk S, Tokatli F (2006) Relationship between morphology, rheology and polygalacturonase production by Aspergillus sojae ATCC 20235 in submerged cultures. Biochem Eng J 32:171–178

Tari C, Gögus N, Tokatli F (2007) Optimization of biomass, pellet size and polygalacturonase production by Aspergillus sojae ATCC 20235 using response surface methodology. Enzyme Microb Technol 40:1108–1116

Ustok FI, Tari C, Gogus N (2007) Solid-state production of polygalacturonase by Aspergillus sojae ATCC 20235. J Biotechnol 127:322–334

Pazouki M, Panda T (2000) Understanding the morphology of fungi. Bioprocess Eng 22:127–143

Paul GC, Priede MA, Thomas CR (1999) Relationship between morphology and citric acid production in submerged Aspergillus niger fermentations. Biochem Eng J 3:121–129

Papagianni M (2004) Fungal morphology and metabolite production in submerged mycelial processes. Biotechnol Adv 22:189–259

Amanullah A, Christensen LH, Hansen K, Nienow AW, Thomas CR (2002) Dependence of morphology on agitation intensity in fed-batch cultures of Aspergillus oryzae and its implications for recombinant protein production. Biotechnol Bioeng 77:815–826

Grimm LH, Kelly S, Krull R, Hempel DC (2005) Morphology and productivity of filamentous fungi. Appl Microbiol Biotechnol 69:375–384

DuBois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Panda T, Naidu GSN, Sinha J (1999) Multiresponse analysis of microbiological parameters affecting the production of pectolytic enzymes by Aspergillus niger: a statistical view. Process Biochem 35:187–195

Nelson N (1944) A photometric adaptation of the Somogyi method for the determination of glucose. J Biol Chem 153:375–380

Somogyi M (1952) Notes on sugar determination. J Biol Chem 195:19–23

Gogus N, Taze BH, Demir H, Tari C, Unluturk S, Lahore MF (2014) Evaluation of orange peel, an industrial waste, for the production of Aspergillus sojae polygalacturonase considering both morphology and rheology effects. Turk J Biol 38:537–548

Oncul S, Tari C, Unluturk S (2007) Effect of various process parameters on morphology, rheology, and polygalacturonase production by Aspergillus sojae in a batch bioreactor. Biotechnol Prog 23:836–845

Nighojkar S, Phanse Y, Sinha D, Nighojkar A, Kumar A (2006) Production of polygalacturonase by immobilized cells of Aspergillus niger using orange peel as inducer. Process Biochem 41:1136–1140

Teixeira MFS, Lima JL, Duran N (2000) Carbon sources effect on pectinase production from Aspergillus japonicus 586. Braz J Microbiol 31:286–290

Galiotou-Panayotou M, Rodis P, Kapantai M (1993) Enhanced polygalacturonase production by Aspergillus niger NRRL-364 grown on supplemented citrus pectin. Lett Appl Microbiol 17:145–148

Grohmann K, Cameron RG, Buslig BS (1995) Fractionation and pretreatment of orange peel by dilute acid hydrolysis. Bioresour Technol 54:129–141

Talebnia F, Pourbafrani M, Lundin M, Taherzadeh MJ (2008) Optimization study of citrus waste saccharification by dilute-acid hydrolysis. Bioresources 3:108–122

Widmer W, Zhou WY, Grohmann K (2010) Pretreatment effects on orange processing waste for making ethanol by simultaneous saccharification and fermentation. Bioresour Technol 101:5242–5249

Buyukkileci AO, Hamamci H, Yucel M (2006) Lactate and ethanol productions by Rhizopus oryzae ATCC 9363 and activities of related pyruvate branch point enzymes. J Biosci Bioeng 102:464–466

Papagianni M, Moo-Young M (2002) Protease secretion in glucoamylase producer Aspergillus niger cultures: fungal morphology and inoculum effects. Process Biochem 37:1271–1278

Friedrich J, Cimerman A, Steiner W (1990) Production of pectolytic enzymes by Aspergillus niger—effect of inoculum size and potassium hexacyanoferrate II-trihydrate. Appl Microbiol Biotechnol 33:377–381

Hermersdorfer H, Leuchtenberger A, Wardsack C, Ruttloff H (1987) Influence of culture conditions on mycelial structure and polygalacturonase synthesis of Aspergillus niger. J Basic Microbiol 27:309–315

Couri S, Pinto GAS, de Senna LF, Martelli HL (2003) Influence of metal ions on pellet morphology and polygalacturonase synthesis by Aspergillus niger 3T5B8. Braz J Microbiol 34:16–21

Malvessi E, da Silveira MM (2004) Influence of medium composition and pH on the production of polygalacturonases by Aspergillus oryzae. Braz Arch Biol Tecn 47:693–702

Beg QK, Bhushan B, Kapoor M, Hoondal GS (2000) Effect of amino acids on production of xylanase and pectinase from Streptomyces sp QG-11-3. World J Microbiol Biotechnol 16:211–213

Hadj-Taieb N, Ayadi M, Trigui S, Bouabdallah F, Gargouri A (2002) Hyperproduction of pectinase activities by a fully constitutive mutant (CT1) of Penicillium occitanis. Enzyme Microb Technol 30:662–666

Villas-Boas SG, Esposito E, de Mendonca MM (2002) Novel lignocellulolytic ability of Candida utilis during solid-substrate cultivation on apple pomace. World J Microbiol Biotechnol 18:541–545

Nakkeeran E, Gowthaman MK, Umesh-Kumar S, Subramanian R (2012) Techno-economic analysis of processes for Aspergillus carbonarius polygalacturonase production. J Biosci Bioeng 113:634–640

Rangarajan V, Rajasekharan M, Ravichandran R, Sriganesh K, Vaitheeswaran V (2010) Pectinase production from orange peel extract and dried orange peel solid as substrates using Aspergillus niger. Int J Biotechnol Biochem 6:445–453

Pedrolli D, Gomes E, Monti R, Carmona E (2008) Studies on productivity and characterization of polygalacturonase from Aspergillus giganteus submerged culture using citrus pectin and orange waste. Appl Biochem Biotechnol 144:191–200

Acknowledgments

This work was supported by TÜBITAK (Turkey) and BMBF (Germany) through the Intensified Cooperation Project of IntenC 107O602 and EUROTRANSBIO, PGSYS/ETB-2008-44.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Buyukkileci, A.O., Lahore, M.F. & Tari, C. Utilization of orange peel, a food industrial waste, in the production of exo-polygalacturonase by pellet forming Aspergillus sojae . Bioprocess Biosyst Eng 38, 749–760 (2015). https://doi.org/10.1007/s00449-014-1315-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-014-1315-1