Abstract

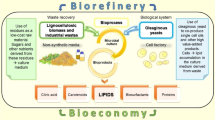

CelTherm is a biochemical process to produce renewable fuels and chemicals from lignocellulosic biomass. The present study’s objective was to determine the level of treatment/purity of the microbial triacylglyceride oil (TAG) necessary to facilitate fuel production. After a unique microbe aerobically synthesizes TAG from biomass-derived sugars, the microbes were harvested and dried then crude TAG was chemically extracted from the residual biomass. Some TAGs were further purified to hydrotreating process requirements. Both grades were then noncatalytically cracked into a petroleum-like intermediate characterized by gas chromatography. Experiments were repeated using refined soybean oil for comparison to previous studies. The products from crude microbial TAG cracking were then further refined into a jet fuel product. Fuel tests indicate that this jet fuel corresponds to specifications for JP-8 military turbine fuel. It was thus concluded that the crude microbial TAG is a suitable feedstock with no further purification required, demonstrating CelTherm’s commercial potential.

Similar content being viewed by others

References

Chew TL, Bhatia S (2008) Catalytic processes towards the production of biofuels in a palm oil and oil palm biomass-based biorefinery. Bioresour Technol 99:7911–7922

Shonnard DR, Williams L, Kalnes TN (2010) Camelina-derived jet fuel and diesel : sustainable advanced biofuels. Environ Prog 29:382–392

Luo Y, Ahmed I, Kubátová A et al (2010) The thermal cracking of soybean/canola oils and their methyl esters. Fuel Process Technol 91:613–617

Chisti Y (2008) Biodiesel from microalgae beats bioethanol. Trends Biotechnol 26:126–131

Parkavi K, Mathumitha B (2011) Review of key research efforts to make algae fuels sustainable. ASTM Spec Tech Publ 1477:566–576

Menon SM, Newman DE, Sircar JC, et al. (2010) Microbial processing of cellulosic feedstocks for fuel

Vasudevan PT, Briggs M (2008) Biodiesel production—current state of the art and challenges. J Ind Microbiol Biotechnol 35:421–430

Kubatova A, Stavova J, Seames W et al (2012) Triacylglyceride thermal cracking: pathways to cyclic hydrocarbons. Energy Fuels 26:672–685

Kubátová A, Luo Y, Šťávová J et al (2011) New path in the thermal cracking of triacylglycerols (canola and soybean oil). Fuel 90:2598–2608

(2008) ASTM D5134-98 standard test method for detailed analysis of petroleum naphthas through n-nonane by capillary gas chromatography. ASTM International, West Conshohocken

(2007) ASTM D5307-97 standard test method for determination of boiling range distribution of crude petroleum by gas chromatography. ASTM International, West Conshohocken

Seames W, Luo Y, Ahmed I et al (2010) The thermal cracking of canola and soybean methyl esters: improvement of cold flow properties. Biomass Bioenergy 34:939–946

Šťávová J, Beránek J, Nelson EP et al (2011) Limits of detection for the determination of mono- and dicarboxylic acids using gas and liquid chromatographic methods coupled with mass spectrometry. J Chromatogr B 879:1429–1438

Sťávová J, Stahl DC, Seames WS, Kubátová A (2012) Method development for the characterization of biofuel intermediate products using gas chromatography with simultaneous mass spectrometric and flame ionization detections. J Chromatogr A 1224:79–88

(2011) ASTM D1655-11b standard specification for aviation turbine fuels. ASTM International, West Conshohocken

(2011) ASTM D6615-11a standard specification for jet B wide-cut aviation turbine fuel. ASTM International, West Conshohocken

(2011) ASTM D975-11 standard specification for diesel fuel oils. ASTM International, West Conshohocken

(2003) ASTM D1298-99 standard test method for density, relative density (specific gravity), or API gravity of crude petroleum and liquid petroleum products by hydrometer method. ASTM International, West Conshohocken

(2011) ASTM D974-11 standard test method for acid and base number by color-indicator titration. ASTM International, West Conshohocken

(2005) ASTM D5972-05 standard test method for freezing point of aviation fuels (automatic phase transition method). ASTM International, West Conshohocken

(2005) ASTM D3828-05 standard test methods for flash point by small scale closed cup tester. ASTM International, West Conshohocken

(2005) ASTM D4809-00 standard test method for heat of combustion of liquid hydrocarbon fuels by bomb calorimeter (Precision method). ASTM International, West Conshohocken

(2011) ASTM D86-11a standard test method for distillation of petroleum products at atmospheric pressure. ASTM International, West Conshohocken

(2010) ASTM D1319-10 standard test method for hydrocarbon types in liquid petroleum products by fluorescent indicator adsorption. ASTM International, West Conshohocken

Lavrenov AV, Bogdanets EN, Chumachenko YA, Likholobov VA (2011) Catalytic processes for the production of hydrocarbon biofuels from oil and fatty raw materials: contemporary approaches. Catal Ind 3:250–259

Raseev S (2003) Thermal and catalytic processes in petroleum refining. Marcel Dekker Inc, New York

Acknowledgments

Partial funding for this work was received from the North Dakota Department of Commerce Centers of Excellence program via the SUNRISE BioProducts Center of Excellence. The assistance of SUNRISE BioProducts staff members Tyrone Garro, Lisa Schmidt, Lee Haag, and Danise Stahl was also valuable in the conduct of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Linnen, M., Seames, W., Kubatova, A. et al. Evaluation of microbial triglyceride oil purification requirements for the CelTherm process: an efficient biochemical pathway to renewable fuels and chemicals. Bioprocess Biosyst Eng 37, 2121–2129 (2014). https://doi.org/10.1007/s00449-014-1190-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-014-1190-9