Abstract

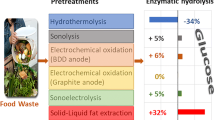

Instant noodle manufacturing waste was used as feedstock to convert it into two products, bioethanol and biodiesel. The raw material was pretreated to separate it into two potential feedstocks, starch residues and palm oil, for conversion to bioethanol and biodiesel, respectively. For the production of bioethanol, starch residues were converted into glucose by α-amylase and glucoamylase. To investigate the saccharification process of the pretreated starch residues, the optimal pretreatment conditions were determined. The bioethanol conversion reached 98.5 % of the theoretical maximum by Saccharomyces cerevisiae K35 fermentation after saccharification under optimized pretreatment conditions. Moreover, palm oil, isolated from the instant noodle waste, was converted into valuable biodiesel by use of immobilized lipase (Novozym 435). The effects of four categories of alcohol, oil-to-methanol ratio, reaction time, lipase concentration and water content on the conversion process were investigated. The maximum biodiesel conversion was 95.4 %.

Similar content being viewed by others

References

Miranda JR, Passarinho PC, Gouveia L (2012) Pre-treatment optimization of Scenedesmus obliquus microalgae for bioethanol production. Bioresour Technol 104:342–348

Kim KH, Eom IY, Lee SM, Cho ST, Choi IG, Choi JW (2012) Applicability of sub- and supercritical water hydrolysis of woody biomass to produce monomeric sugars for cellulosic bioethanol fermentation. J Ind Eng Chem 16:918–922

Zhu MJ, Zhu ZS, Liang L, Xu WX (2012) Production of bioethanol from sugarcane biomass using NH4OH–H2O2 pretreatment and simultaneous saccharification and co-fermentation. Biotechnol Bioprocess Eng 17:316–325

Hashem M, Darwish SMI (2010) Production of bioethanol and associated by-products from potato starch residue stream by Saccharomyces cerevisiae. Biomass Bioenergy 34:953–959

Chen H, Qiu W (2010) Key technologies for bioethanol production from lignocellulose. Biotechnol Adv 28:556–562

Shanavas S, Padmaja G, Moorthy SN, Sajeev MS, Sheriff JT (2011) Process optimization for bioethanol production from cassava starch using novel eco-friendly enzymes. Biomass Bioenergy 35:901–909

Food Journal (2011) Food distribution yearbook of Korea. Food Journal Co. Ltd, South Korea

Yan SB, Li J, Chen XS, Wu JY, Wang PC, Ye JF, Yao JM (2011) Enzymatical hydrolysis of food waste and ethanol production from the hydrolysis. Renew Energy 36:1259–1265

Rojan PJ, Anisha GS, Nampoothiri KM, Pandey A (2011) Micro and macro algal biomass: a renewable source for bioethanol. Bioresour Technol 102:186–193

Lee H, Cho DH, Kim YH, Shin SJ, Kim SB, Han SO, Lee J, Kim SW, Park C (2011) Tolerance of Saccharomyces cerevisiae K35 to lignocellulose-derived inhibitory compounds. Biotechnol Bioprocess Eng 16:755–760

Iliana BM, Axayácatl RGG, Edgar SM, Juan SAB (2011) A Simple metabolic flux balance analysis of biomass and bioethanol production in Saccharomyces cerevisiae fed-batch cultures. Biotechnol Bioprocess Eng 16:13–22

Talebnia F, Karakashev D, Angelidaki I (2010) Production of bioethanol from wheat straw: an overview on pretreatment, hydrolysis and fermentation. Bioresour Technol 101:4744–4753

Won KY, Kim YS, Oh KK (2012) Comparison of bioethanol production of simultaneous saccharification & fermentation and separation hydrolysis & fermentation from cellulose-rich barley straw. Korean J Chem Eng 29(10):1341–1346

Lee SJ, Kim SB, Kang SW, Han SO, Park C, Kim SW (2012) Effect of crude glycerol-derived inhibitors on ethanol production by Enterobacter aerogenes. Bioprocess Biosyst Eng 35:85–92

Itsuki W, Naonori M, Akira A, Riki S, Ken T, Toshihide N (2012) Ethanol production by repeated-batch simultaneous saccharification and fermentation (SSF) of alkali-treated rice straw using immobilized Saccharomyces cerevisiae cells. Bioresour Technol 123:695–698

Seong PJ, Jeon BW, Lee M, Cho DH, Kim DK, Jung KS, Kim SW, Han SO, Kim YH, Park C (2011) Enzymatic coproduction of biodiesel and glycerol carbonate from soybean oil and dimethyl carbonate. Enzyme Microb Technol 48:505–509

Lee JH, Kim SB, Park C, Kim SW (2010) Effect of a buffer mixture system on the activity of lipases during immobilization process. Bioresour Technol 101:566–570

Lee JH, Kim SB, Kang SW, Song YS, Park C, Han SO, Kim SW (2011) Biodiesel production by a mixture of Candida rugosa and Rhizopus oryzae lipases using a supercritical carbon dioxide process. Bioresour Technol 102:2105–2108

Lee JH, Kwon CH, Kang JW, Park C, Tea B, Kim SW (2009) Biodiesel production from various oil under supercritical fluid conditions by Candida antartica lipase B using a stepwise reaction method. Appl Biochem Biotechnol 156:454–464

Simone B, Charles EW (2010) Review: continuous hydrolysis and fermentation for cellulosic ethanol production. Bioresour Technol 101:4862–4874

Han M, Kim Y, Chung B, Kim Y, Choi GW (2011) Bioethanol production from optimized pretreatment of cassava stream. Korean J Chem Eng 28(1):119–125

Kim SB, Lee SJ, Lee JH, Jung YR, Thapa LP, Kim JS, Um Y, Park C, Kim SW (2013) Pretreatment of rice straw with combined process using dilute sulfuric acid and aqueous ammonia. Biotechnol Biofuels 6:109

Yu KO, Kim SW, Han SO (2010) Engineering of glycerol utilization pathway for ethanol production by Saccharomyces cerevisiae. Bioresour Technol 101:4157–4161

Frick O, Wittmann C (2005) Characterization of the metabolic shift between oxidative and fermentative growth in Saccharomyces cerevisiae by comparative 13C flux analysis. Microb Cell Fact 4:30

Gog A, Roman M, Tosa M, Paizs C, Irimie FD (2012) Biodiesel production using enzymatic transesterification—current state and perspectives. Renew Energy 39:10–16

Jang MG, Kim DK, Soon C, Park SC, Lee JS, Kim SW (2012) Biodiesel production from crude canola oil by two-step enzymatic processes. Renew Energy 42:99–104

Jung H, Lee Y, Kim D, Han SO, Kim WK, Lee J, Kim YH, Park C (2012) Enzymatic production of glycerol carbonate from by-product after biodiesel manufacturing process. Enzyme Microb Technol 51:143–147

Talukder MR, Wu JC, Nguyen TBV, Ng MF, Melissa YLS (2009) Novozym 435 for production of biodiesel from unrefined palm oil: comparison of methanolysis methods. J Mol Catal B Enzym 60:106–122

Talukder MR, Das P, Fang TS, Wu JC (2011) Enhanced enzymatic transesterification of palm oil to biodiesel. Biochem Eng J 55:119–122

Park JY, Lee JS, Wang ZM, Kim DK (2010) Production and characterization of biodiesel from trap grease. Korean J Chem Eng 27(6):1791–1795

Egues I, Alriols MG, Herseczki Z, Marton G, Labidi J (2010) Hemicelluloses obtaining from rapeseed cake residue generated in the biodiesel production process. J Ind Eng Chem 16:293–298

Go A, Ko JK, Lee SJ, Kim SW, Han SO, Lee J, Woo HM, Um Y, Nam J, Park C (2012) Process design and evaluation of value-added chemicals production from biomass. Biotechnol Bioprocess Eng 17:1055–1061

Yan J, Li A, Xu Y, Ngo TPN, Phua S, Li Z (2012) Efficient production of biodiesel from waste grease: one pot esterification and transesterification with tandem lipases. Bioresour Technol 123:332–337

Saqib M, Mumtaz MW, Mahmood A, Abdullah MI (2012) Optimized biodiesel production and environmental assessment of produced biodiesel. Biotechnol Bioprocess Eng 17:617–623

Saifuddin N, Raziah AZ, Farah HN (2009) Production of biodiesel from high acid value waste cooking oil using an optimized lipase enzyme/acid-catalyzed hybrid process. J Chem 6(S1):S485–S495

Tan KT, Lee KT, Mohamed AR (2011) Potential of waste palm cooking oil for catalyst-free biodiesel production. Energy 36:2085–2088

Acknowledgments

This work was supported by the Advanced Biomass R&D Center (ABC-2011-0031360) of Global Frontier Project funded by the Ministry of Science, ICT and Future Planning of Korea and Advanced Production Technology Development Program (309016-5) of the Ministry of Agriculture, Food and Rural Affairs, Republic of Korea and Creative Allied Project (CAP) of the Korea Research Council of Fundamental Science and Technology (KRCF)/Korea Institute of Science and Technology (KIST) (2E24832).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yang, X., Lee, J.H., Yoo, H.Y. et al. Production of bioethanol and biodiesel using instant noodle waste. Bioprocess Biosyst Eng 37, 1627–1635 (2014). https://doi.org/10.1007/s00449-014-1135-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-014-1135-3