Abstract

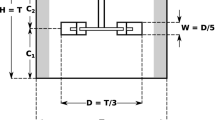

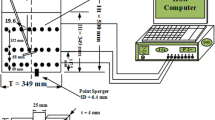

A combined computational fluid dynamics (CFD) and population balance model (PBM) approach has been applied to simulate hydrodynamics and mass transfer in a 0.18 m3 gas–liquid stirred bioreactor agitated by (1) a Rushton turbine, and (2) a new pitched blade geometry with rotating cartridges. The operating conditions chosen were motivated by typical settings used for culturing mammalian cells. The effects of turbulence, rotating flow, bubbles breakage and coalescence were simulated using the k–ε, multiple reference frame (MRF), Sliding mesh (SM) and PBM approaches, respectively. Considering the new pitched blade geometry with rotating aeration microspargers, \(k_{\text{L}} a\) mass transfer was estimated to be 34 times higher than the conventional Rushton turbine set-up. Notably, the impeller power consumption was modeled to be about 50 % lower. Independent \(k_{\text{L}} a\) measurements applying the same operational conditions confirmed this finding. Motivated by these simulated and experimental results, the new aeration and stirring device is qualified as a very promising tool especially useful for cell culture applications which are characterized by the challenging problem of achieving relatively high mass transfer conditions while inserting only low stirrer energy.

Similar content being viewed by others

References

Nienow AW (2006) Reactor engineering in large animal cell culture. Cytotechnology 50:9–33

Hewitt CJ, Nienow AW (2007) The scale-up of microbial batch and fed-batch fermentation processes. Adv Appl Microbiol 62:105–135

Takors R (2012) Scale-up of microbial processes: impacts, tools and open questions. J Biotechnol 160:3–9

Lara AR, Galindo E, Ramirez OT, Palomares LA (2006) Living with heterogeneities in bioreactors. Mol Biotechnol 34:355–381

Junker BH (2004) Scale-up Methodologies for Escherichia coli and Yeast Fermentation Process. J of Biosci and Bioeng 97:347–364

Schmidt FR (2005) Optimization and scale up of industrial fermentation processes. Appl Microbiol Biotechnol 68:425–435

EP 1479758 Vorrichtung zum Begasen, vorzugsweise für mikrobiologische Fermentation und Kultivierung von Zellen, erteilt 25.04.2007

Jenne M, Reuss M (1999) A critical assessment on the use of k–e turbulence models for simulation of the turbulent liquid flow induced by Rushton turbine in baffled stirred-tank reactors. Chem Eng Sci 54:3921–3941

Luo JY, Issa RI, Gosman AD (1994) Prediction of impeller induced flows in mixing vessels using multiple frames of reference. IchemE Symposium Series. Inst Chem Eng 136:549–556

Micale GA, Grisafi F (1999) Prediction of flow fields in a dual-impeller stirred tank. AIChE J 45:445–464

Rutherford K, Lee C, Mahmoudi SM, Yianneskis M (1996) Hydrodynamic characteristics of dual Rushton impeller stirred vessels. AIChE J 42:332–346

Tabor AD, Gosman G, Issa RI (1996) Numerical simulation of the flow in a mixing vessel stirred by a Rushton turbine. IChemE Symposium Series 140:25–34

Bakker, Van Den Akker HE (1994) A computational model for the gas–liquid flow in stirred reactors Transactions of IChemE 72:594–606

Kerdouss F, Bannari A, Proulx P, Bannari R, Skrga M, Labrecque Y (2008) Two-phase mass transfer coefficient prediction in stirred vessel with a CFD model. Comput Chem Eng 32:1943–1955

Kerdouss F, Kiss L, Proulx P, Bilodeau JF, Dupuis C (2005) Mixing characteristics of an axial flow rotor: experimental and numerical study. Int J Chem React Eng 3:35

Kerdouss F, Bannari A, Proulx P, Bannari R, Skrga M, Labrecque Y (2007) Two-phase mass transfer coefficient prediction in stirred vessel with a CFD model. Comput Chem Eng 3:1–13

Lane GL, Schwarz MP, Evans GM (2005) Numerical modeling of gas–liquid flow in stirred tank. Chem Eng Sci 60:2203–2214

Venneker CH, Van Den Derksen H (2002) Population balance modeling of aerated stirred vessels based on CFD. AIChE J 48:673–684

Lide DR (2005) CRC Handbook of Chemistry and Physics, Internet Version 2005, CRC Press, Boca Raton, FL. http://www.hbcpnetbase.com

Kasat GR, Pandit AB, Ranade VV (2008) CFD Simulation of Gas-Liquid Flows in a Reactor Stirred by Dual Rushton Turbines. Int J Chem React Eng 6:1–28

Lu, Wei-Ming (2004) Multiple impeller gas–liquid contactors. Taipei, Taiwan

Ranade VV, Dommeti JB (1990) Computational snapshot of flow generated by axial impellers in baffled stirred vessels. J Chem 74:476–484

Ranade VV (2002) In: Computational flow modeling for chemical reactor engineering, Process Systems Engineering Series. Academic Press, New York

Jahoda M, Tomášková L, Moštěk M (2009) CFD prediction of liquid homogenization in a gas–liquid stirred tank. Chem Eng Res Des 87:460–467

Marshall EM, Bakker A (2002) Computational fluid mixing. Lebanon, New Hampshire, USA. http://www.fluent.com

ANSYS FLUENT v13 (2012) User’s Manual, Centrera Resource Park, 10 Cavendish Court, Lebanon. Fluent Inc

Ishii M, Zuber N (1979) Drag coefficient and relative velocity in bubbly, droplet or particulate flows. AIChE J 25:843–855

Elgobashi SE, Rizk MA (1989) A two-equation turbulence model for dispersed dilute confined two-phase flows. Int J Multiph Flow 15:119–133

Hounslow MJ, Ryall RL, Marschall VR (1988) A Discretized Population Balance for Nucleation, Growth and Aggregation. AIChE J 34:1821–1832

Litster JD, Smit DJ, Hounslow MJ (1995) Adjustable discretization population balance for growth and aggregation. AIChE J 41:591–603

Ramkrishna (2000) In: Population balances: theory and applications to particulate systems in engineering. Academic Press, New York

Chen P, Dudukovic MP, Sanyal J (2005) Numerical simulation of bubble columns flows: effect of different breakup and coalescence closures. Chem Eng Sci 60:1085–1101

Hagesaether L, Jakobsen H, Hjarbo A, Svendsen HA (2000) Coalescence and breakup module for implementation in CFD codes. Eur Symp Comput Aided Process Eng 1:367–372

Sanyal J, Marchisio DL, Fox RO, Dhanasekharan K (2005) On the comparison between population balance models for CFD simulation of bubble columns. Ind Eng Chem Res 44:5063–5072

Luo JY, Issa RI, Gosman AD (1994) Prediction of impeller induced flows in mixing vessels using multiple frames of reference. IchemE Symposium Series. Inst Chem Eng 136:549–556

Gimbun J, Rielly CD, Nagy ZK (2009) Modeling of mass transfer in gas–liquid stirred tanks agitated by Rushton turbine and CD-impeller: a scale-up study. Chem Eng Res Des 87:437–451

Sanyal J, Marchisio DL, Fox RO, Dhanasekharan K (2005) On the comparison between population balance models for CFD simulation of bubble columns. Ind Eng Chem Res 44:5063–5072

Oh SKW, Nienow AW, Al-Rubeai M, Emery AN (1989) The effects of agitation intensity with and without continuous sparging on the growth and anti-body production of hybridoma cells. J Biotechnol 12:45–62

Luo JY, Issa RI, Gosman AD (1993) Full flow field computation of mixing in baffled stirred vessels. Trans IChemE 71:342–344

Dhanasekharan K, Sanyal J, Jain A, Haidari A (2005) A generalized approach to model oxygen transfer in bioreactors using population balances and computational fluid dynamics. Chem Eng Sci 60:213–218

Acknowledgments

The study is part of a cooperation project together with Industrieberatung Kloss (IBK, Taufkirchen, Germany) and the company MUT Tschamber Misch-und Trenntechnik GmbH (Wehr, Germany) and funded by AIF (Grant number: KF 2921901AJ1/KF 2915501AJ1).

Conflict of interest

The authors have declared no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gelves, R., Dietrich, A. & Takors, R. Modeling of gas–liquid mass transfer in a stirred tank bioreactor agitated by a Rushton turbine or a new pitched blade impeller. Bioprocess Biosyst Eng 37, 365–375 (2014). https://doi.org/10.1007/s00449-013-1001-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-013-1001-8