Abstract

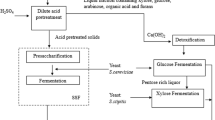

The present work aimed to study the viability of the use of sugarcane molasses and corn steep liquor (CSL) in a sequential inulinase production performing an up-stream pretreatment of these agroindustrial residues. A sequential strategy was used applying three central composite rotatable designs (CCRDs) to optimise medium composition, followed by a down-stream step. The medium containing 150 g L−1 molasses, 50 g L−1 CSL and 6 g L−1 yeast extract, yielded a maximum inulinase production of 1,294 ± 7 U mL−1, after 72 h of fermentation. A down-stream evaluation was carried out using an expanded bed of Streamline DAE resin (Pharmacia), with and without the up-stream treatment. The results showed that the enzyme could not be recovered from the non-pretreated medium, whereas a yield of 91% was obtained in the adsorption stage from the medium prepared with the up-stream treatment, showing the viability of producing the enzyme inulinase from agroindustrial residues using the integrated process.

Similar content being viewed by others

References

Gill PK, Manhas RK, Singh P (2006) Purification and properties of a heat-stable exoinulinase isoform from Aspergillus fumigatus. Bioresource Technol 97:894–902

Vandamme EJ, Derycke DG (1983) Microbial inulinases: fermentation process, properties and application. Adv Appl Microbiol 29:139–176

Zhang L, Zhao C, Zhu D, Otha Y, Wang Y (2004) Purification and characterization of inulinase from Aspergillus niger AF10 expressed in Picchia Pastoris. Protein Expres Purif 35:272–275

Gupta AK, Davinder PS, Kaur N, Singh R (1994) Production, purification and immobilization of inulinase from Kluyveromyces fragilis. J Chem Technol Biotechnol 59:377–385

Silva-Santisteban BOY, Maugeri F (2005) Agitation, aeration and shear stress as key factors in inulinase production by Kluyveromyces marxianus. Enzyme Microb Tech 36:717–724

Wei W, Zheng Z, Liu Y, Zhu X (1998) Optimizing the culture conditions for higher inulinase production by Kluyveromyces sp. Y-85 and scaling-up fermentation. J Ferment Bioeng 86:395–399

Cazetta ML, Martins PMM, Monti R, Contiero J (2005) Yacon (Polymnia sanchifolia) extract as a substrate to produce inulinase by Kluyveromyces marxianus var. bulgaricus. J Food Eng 66:301–305

Rouwenhorst RJ, Visser LE, Ban AVD, Scheffers WA, Dijken JPV (1998) Production, distribution and kinetic properties of inulinase in continuous cultures of Kluyveromyces marxianus CBS 6556. Appl Environ Microbiol 54:1131–1137

Lazarridou A, Roukas T, Biliaderis CG, Vaiakousi H (2002) Characterization of pullulan produced from beet molasses by Aureobasidium pullulans in a stirred tank reactor under varying agitation. Enzyme Microb Tech 31:122–132

Roukas T (1998) Pretreatment of beet molasses to increase pullulan production. Process Biochem 33:805–810

Makino Y (2004) Seleção de linhagens de Kluyveromyces marxianus produtoras de inulinase visando a obtenção de frutooligossacarídeos: caracterização da enzima e otimização das etapas de produção e separação. PhD thesis, FEA/UNICAMP, Campinas (in portuguese)

Miller GL (1959) Use of dinitrosalisylic acid reagent for determination of reducing sugar. Ana Chem 31:426–428

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the folin phenol reagent. J Biol Chem 193:265–275

Fachin D, Loey AMV, Nguyen BL, Verlent I, Indrawati M, Hedricks ME (2002) Comparative study of the inactivation kinetics of pectinmethylesterase in tomato juice and purified form. Biotech Progress 18:739–744

Kalil SJ, Suzan R, Maugeri F, Rodrigues MI (2001) Optimization of inulinase production by Kluyveromyces marxianus using fatorial design. Appl Biochem Biotechnol 94:257–264

Mazutti MA, Bender JP, Di Luccio M, Treichel H (2006) Optimization of inulinase production by solid-state fermentation using sugarcane bagasse as substrate. Enzyme Microb Tech 39:56–59

Selvakumar P, Pandey A (1999) Solid state fermentation for the synthesis of inulinase from staphylococcus sp. and Kluyveromyces marxianus. Process Biochem 34:851–855

Pessoa A, Hartmann R, Vitolo M, Hustedt H (1996) Recovery of extracellular inulinase by expanded bed adsorption. J Biotechnol 51:89–95

Kalil SJ, Maugeri F, Rodrigues MI (2005) Ion exchange expanded bed chromatography for the purification of an extracelular inulinase from Kluyveromyces marxianus. Process Biochem 40:581–586

Cruz-Guerrero A, Garcia-Peña I, Barzana E, Racia-Garibay M, Gómez-Ruiz L (1995) Kluyveromyces marxianus CDBB-L-278: a wild inulinase hyporproducing strain. J Ferment Bioeng 80:159–163

Zittan L (1981) Enzymatic hydrolysis of inulin—an alternative way to fructose production. Starke 33:373–377

Kushi RT, Monti R, Contiero J (2000) Production, purification and characterization of an extracelular inulinase from Kluyveromyces marxianus var. bulgaricus. J Ind Microbiol Biotechnol 25:63–69

Ettalibi M (2001) Baratti JC Sucrose hydrolysis by the thermostable immobilized inulinases from Aspergillus ficum. Enzyme Microb Tech 28:596–601

Rouwenhorst RJ, Hensing M, Verbakel J, Scheffers WA, Dijken JPV (1990) Structure and properties of the extracellular inulinase of Kluyveromyces marxianus CBS 6556. Appl Environ Microbiol 56:3337–3345

Vullo DL, Coto CE, Sinerizz F (1991) Characteristics of an inulinase produced by Bacillus subtilis 430A, a strain isolated from the Rhizosphere of Vernonia herbacea (Vell Rusby). Appl Environ Microbiol 57:2392–2394

Catana R, Ferreira BS, Cabral JMS, Fernandes P (2005) Immobilization of inulinase for sucrose hydrolysis. Food Chem 91:517–520

Acknowledgments

The authors are grateful to CNPq, CAPES and FAPESP for their financial support of this research and for the scholarships awarded.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Treichel, H., Mazutti, M.A., Filho, F.M. et al. Technical viability of the production, partial purification and characterisation of inulinase using pretreated agroindustrial residues. Bioprocess Biosyst Eng 32, 425–433 (2009). https://doi.org/10.1007/s00449-008-0262-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-008-0262-0