Abstract.

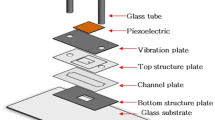

We built a high-speed, pneumatic pressure clamp to stimulate patch-clamped membranes mechanically. The key control element is a newly designed differential valve that uses a single, nickel-plated piezoelectric bending element to control both pressure and vacuum. To minimize response time, the valve body was designed with minimum dead volume. The result is improved response time and stability with a threefold decrease in actuation latency. Tight valve clearances minimize the steady-state air flow, permitting us to use small resonant-piston pumps to supply pressure and vacuum. To protect the valve from water contamination in the event of a broken pipette, an optical sensor detects water entering the valve and increases pressure rapidly to clear the system. The open-loop time constant for pressure is 2.5 ms for a 100-mmHg step, and the closed-loop settling time is 500–600 µs. Valve actuation latency is 120 µs. The system performance is illustrated for mechanically induced changes in patch capacitance.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Electronic Publication

Rights and permissions

About this article

Cite this article

Besch, S.R., Suchyna, T. & Sachs, F. High-speed pressure clamp. Pflugers Arch - Eur J Physiol 445, 161–166 (2002). https://doi.org/10.1007/s00424-002-0903-0

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s00424-002-0903-0