Abstract

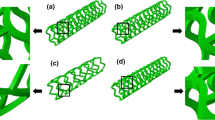

Flexibility is critical to the braided stent in curing vascular diseases, but there is no theoretical method to characterize its bending stiffness. In this paper, firstly based on the theory of mechanical spring, derivations of an explicit theoretical formula are made to calculate the bending stiffness of the braided stent. The formula does ignore the change of the braiding angle, which, according to a geometric analysis, can get neutralized and has rare effects on the result. Next, an experiment on a braided tube and numerical simulations on stents are conducted, which provide validations to the theoretical formula through comparisons of bending stiffness, stress distributions, and bending angle versus moment curves. Finally, a parametric analysis based on the formula is carried out. It finds that bending stiffness is mostly affected by the wire diameter, but a smaller braiding angle is the key to improving the bending flexibility while keeping a sufficient radial stiffness. It also finds that the formula is applicable to other braiding configurations, such as dual-layer and regular braiding stents. The formula provides theoretical foundations for the stiffness design of the braided stent and can simplify the design process.

Similar content being viewed by others

References

Qiu, D., Barakat, M., Hopkins, B., Ravaghi, S., Azadani, A.N.: Transcatheter aortic valve replacement in bicuspid valves: the synergistic effects of eccentric and incomplete stent deployment. J. Mech. Behav. Biomed. 121, 104621 (2021). https://doi.org/10.1016/j.jmbbm.2021.104621

Simao, M., Ferreira, J.M., Mora-Rodriguez, J., Fragata, J., Ramos, H.M.: Behaviour of two typical stents towards a new stent evolution. Med. Biol. Eng. Comput. 55, 1019–1037 (2017). https://doi.org/10.1007/s11517-016-1574-x

Brinjikji, W., Murad, M.H., Lanzino, G., Cloft, H.J., Kallmes, D.F.: Endovascular treatment of intracranial aneurysms with flow diverters: a meta-analysis. Stroke 44, 442–447 (2013). https://doi.org/10.1161/STROKEAHA.112.678151

Kojima, M., Irie, K., Masunaga, K., Sakai, Y., Negoro, M.: Hybrid stent device of flow-diverting effect and stent-assisted coil embolization formed by fractal structure. Med. Biol. Eng. Comput. 54, 831–841 (2015). https://doi.org/10.1007/s11517-015-1374-8

Shimizu, S., Naitoh, I., Okumura, F., Hirano, A., Miyabe, K., Nishi, Y., Takada, H., Haneda, K., Anbe, K., Yoshida, M., Kondo, H., Sano, H., Hayashi, K., Kataoka, H.: One-step versus two-step distal self-expandable metal stent placement: a multicenter prospective randomized trial. J. Gastroenterol. Hepatol 36, 2015–2021 (2021). https://doi.org/10.1111/jgh.15393

Duerig, T.W., Wholey, M.: A comparison of balloon-and self-expanding stents. Minim. Invasive. Ther. 11, 173–178 (2002). https://doi.org/10.1080/136457002760273386

De Beule, M., Van Cauter, S., Mortier, P., Van Loo, D., Van Impe, R., Verdonck, P., Verhegghe, B.: Virtual optimization of self-expandable braided wire stents. Med. Eng. Phys. 31, 448–453 (2009). https://doi.org/10.1016/j.medengphy.2008.11.008

Hu, J.: 3-D Fibrous Assemblies: Properties, Applications and Modelling of Three-Dimensional Textile Structures. CRC Press, New York (2008)

Johnston, C.R., Lee, K., Flewitt, J., Moore, R., Dobson, G.M., Thornton, G.M.: The mechanical properties of endovascular stents: an in vitro assessment. Cardiovasc. Eng. 10, 128–135 (2010). https://doi.org/10.1007/s10558-010-9097-9

Bosiers, M., Deloose, K., Verbist, J., Peeters, P.: Carotid artery stenting: which stent for which lesion? Vascular 13, 205–210 (2005). https://doi.org/10.1258/rsmvasc.13.4.205

de Vries, E.E., Kok, M., Hoving, A.M., Slump, C.H., Toorop, R.J., de Borst, G.J.: (In)comparability of carotid artery stent characteristics: a systematic review on assessment and comparison with manufacturer data. Cardiovasc. Interv. Radiol. 43, 1430–1437 (2020). https://doi.org/10.1007/s00270-020-02499-1

Fu, W., Cheng, G., Yan, R., Qiao, A.: Numerical investigations of the flexibility of intravascular braided stent. J. Mech. Med. Biol. 17, 1750075 (2017). https://doi.org/10.1142/S0219519417500750

Ma, J., You, Z., Byrne, J., Rizkallah, R.R.: Design and mechanical properties of a novel cerebral flow diverter stent. Ann. Biomed. Eng. 42, 960–970 (2014). https://doi.org/10.1007/s10439-013-0967-3

Fontaine, A.B., Spigos, D.G., Eaton, G., Das Passos, S., Christoforidis, G., Khabiri, H., Jung, S.: Stent-induced intimal hyperplasia: are there fundamental differences between flexible and rigid stent designs? J. Vasc. Interv. Radiol. 5, 739–744 (1994). https://doi.org/10.1016/S1051-0443(94)71593-1

Colombo, A., Stankovic, G., Moses, J.W.: Selection of coronary stents. J. Am. Coll. Cardiol. 40, 1021–1033 (2002). https://doi.org/10.1016/S0735-1097(02)02123-X

Liu, Y., Zhu, G., Yang, H., Wang, C., Zhang, P., Han, G.: Bending behaviors of fully covered biodegradable polydioxanone biliary stent for human body by finite element method. J. Mech. Behav. Biomed. 77, 157–163 (2018). https://doi.org/10.1016/j.jmbbm.2017.08.023

Wahl, A.M.: Mechanical Spring. McGraw-Hill, New York (1963)

Jedwab, M.R., Clerc, C.O.: A study of the geometrical and mechanical properties of a self-expanding metallic stent–theory and experiment. J. Appl. Biomater. 4, 77–85 (1993). https://doi.org/10.1002/jab.770040111

Agrawal, C.M., Clark, C.G.: Deformation characteristics of a bioabsorbable intravascular stent. Investig. Radiol. 27, 1020–1024 (1993). https://doi.org/10.1097/00004424-199212000-00007

Nuutinen, J.P., Clerc, C., Tormala, P.: Theoretical and experimental evaluation of the radial force of self-expanding braided bioabsorbable stents. J. Biomater. Sci.-Polym. E 14, 677–687 (2003). https://doi.org/10.1163/156856203322274932

Wang, R., Ravi-Chandar, K.: Mechanical response of a metallic aortic stent-part I: pressure-diameter relationship. J. Appl. Mech.-T ASME 71, 697–705 (2004). https://doi.org/10.1115/1.1782650

Mckenna, C.G., Vaughan, T.J.: An experimental evaluation of the mechanics of bare and polymer-covered self-expanding wire braided stents. J. Mech. Behav. Biomed. 103, 103549 (2020). https://doi.org/10.1016/j.jmbbm.2019.103549

Giuliodori, A., Hernandez, J.A., Fernandez-Sanchez, D., Galve, I., Soudah, E.: Numerical modeling of bare and polymer-covered braided stents using torsional and tensile springs connectors. J. Biomech. 123, 110459 (2021). https://doi.org/10.1016/j.jbiomech.2021.110459

Kim, J.H., Kang, T.J., Yu, W.R.: Mechanical modeling of self-expandable stent fabricated using braiding technology. J. Biomech. 41, 3202–3212 (2008). https://doi.org/10.1016/j.jbiomech.2008.08.005

Zhao, S., Liu, X., Gu, L.: The impact of wire stent fabrication technique on the performance of stent placement. J. Med. Devices 6, 011007 (2012). https://doi.org/10.1115/1.4005788

Ni, X., Pan, C., Prusty, B.G.: Numerical investigations of the mechanical properties of a braided non-vascular stent design using finite element method. Comput. Methods Biomech. Biomed. Eng. 18, 1117–1125 (2015). https://doi.org/10.1080/10255842.2013.873420

Fu, W., Xia, Q., Yan, R., Qiao, A.: Numerical investigations of the mechanical properties of braided vascular stents. Bio-med. Mater. Eng. 29, 81–94 (2018). https://doi.org/10.3233/BME-171714

Rawal, A., Saraswat, H., Sibal, A.: Tensile response of braided structures: a review. Text. Res. J. 85, 2083–2096 (2015). https://doi.org/10.1177/004051751557633

Suzuki, T., Takao, H., Fujimura, S., Dahmani, C., Ishibashi, T., Mamori, H., Fukushima, N., Murayama, Y., Yamamoto, M.: Relationships between geometrical parameters and mechanical properties for a helical braided flow diverter stent. Technol. Health Care 25, 611–623 (2017). https://doi.org/10.3233/THC-160535

Müller-Hülsbeck, S., Schäfer, P.J., Charalambous, N., Schaffner, S.R., Heller, M., Jahnke, T.: Comparison of carotid stents: an in-vitro experiment focusing on stent design. J. Endovasc. Ther. 16, 168–177 (2009). https://doi.org/10.1583/08-2539.1

Liu, Y., Wang, C., Zhang, Y., Zhang, P., Han, G.: Comparative bending behaviors between fully covered and bare biodegradable polydioxanone biliary stents using a numerical approach. Text. Res. J. 89, 2569–2582 (2019). https://doi.org/10.1177/0040517518797342

Müller-Hülsbeck, S., Schäfer, P.J., Charalambous, N., Yagi, H., Heller, M., Jahnke, T.: Comparison of second-generation stents for application in the superficial femoral artery: an in vitro evaluation focusing on stent design. J. Endovasc. Ther. 17, 767–776 (2010). https://doi.org/10.1583/10-3069.1

Rebelo, R., Vila, N., Fangueiro, R., Carvalho, S., Rana, S.: Influence of design parameters on the mechanical behavior and porosity of braided fibrous stents. Mater. Des. 86, 237–247 (2015). https://doi.org/10.1016/j.matdes.2015.07.051

McKenna, C.G., Vaughan, T.J.: A finite element investigation on design parameters of bare and polymer-covered self-expanding wire braided stents. J. Mech. Behav. Biomed. 115, 104305 (2021). https://doi.org/10.1016/j.jmbbm.2020.104305

Fu, W., Li, L., Qiao, A.: Numerical simulation of flattening phenomenon in braided stent during bending deformation. Beijing Biomed. Eng. 39(5), 455–461 (2020). https://doi.org/10.3969/j.issn.1002-3208.2020.05.002. (in Chinese)

Dottori, S., Flamini, V., Vairo, G.: Mechanical behavior of peripheral stents and stent-vessel interaction: a computational study. Int. J. Comput. Methods Eng. 17, 196–210 (2016). https://doi.org/10.1080/15502287.2016.1188530

Alherz, A.I., Tanweer, O., Flamini, V.: A numerical framework for the mechanical analysis of dual-layer stents in intracranial aneurysm treatment. J. Biomech. 49, 2420–2427 (2016). https://doi.org/10.1016/j.jbiomech.2016.02.026

Zhang, Y., Liu, H., Wang, D.: Handbook of Spring. China Machine Press, Beijing (2017).. (in Chinese)

Shang, Z., Ma, J., You, Z., Wang, S.: A foldable manipulator with tunable stiffness based on braided structure. J. Biomed. Mater. Res. B 108, 316–325 (2020). https://doi.org/10.1002/jbm.b.34390

Simons, J.W, Shockey, D.A.: Mechanical testing devices for characterizing stents. In: SMST Conference California, pp. 7–11 (2006)

Shang, Z., Wang, S., You, Z., Ma, J.: A hybrid tubular braid with improved longitudinal stiffness for medical catheter. J. Mech. Med. Biol. 19, 1950003 (2019). https://doi.org/10.1142/S0219519419500039

Alpyildiz, T.: 3D geometrical modelling of tubular braids. Text. Res. J. 82, 443–453 (2012). https://doi.org/10.1177/0040517511427969

Kyosev, Y.: Generalized geometric modeling of tubular and flat braided structures with arbitrary floating length and multiple filaments. Text. Res. J. 86, 1270–1279 (2016). https://doi.org/10.1177/0040517515609261

Shang, Z., Ma, J., You, Z., Wang, S.: Lateral indentation of a reinforced braided tube with tunable stiffness. Thin Walled Struct. 149, 106608 (2020). https://doi.org/10.1016/j.tws.2020.106608

Kyosev, Y.: Braiding Technology for Textiles: Principles, Design and Processes. Elsevier, Cambridge (2014)

Saraswat, H., Rawal, A., Singh, R.: Tensile behaviour of multi-layered braided structures. J. Mater. Sci. 49, 6427–6436 (2014). https://doi.org/10.1007/s10853-014-8372-3

Funding

This work was supported by the Science Foundation of Zhejiang Sci-Tech University (Grant 21022312-Y).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shang, Z., Ma, J. Bending stiffness characterization of braided stent using spring-based theoretical formula. Arch Appl Mech 93, 947–960 (2023). https://doi.org/10.1007/s00419-022-02307-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-022-02307-x