Abstract

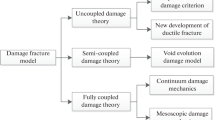

This work proposes a new constitutive model that takes into account the asymmetry of Ti–6Al–4V, its microstructural state and its pronounced anisotropy in order to improve the use of this titanium alloy in biomechanics and aeronautics in particular. The choice of the stress directions and their effect on shaping procedures in light of accounting the effect of heat treatment on the behavior of Ti–6Al–4V, hardness and microstructural defects is important. The fracture surfaces of a material specimen subjected to traction/compression is examined using scanning electron microscope. An appropriate choice of the model is necessary through experimental validation. The use of this alloy in the biomechanical field brings into consideration several factors such as different solicitations and uniaxial loads, and tension-compression asymmetry...as well as in the aeronautical field other factors such as material strength and ductility in shaping under certain heat treatment are considered.

Similar content being viewed by others

References

Leyens, C., Peters, M.: Titanium and Titanium Alloys Fundamentals and Applications. Wiley, Hoboken (2003)

Searles, T., Tiley, J., Tanner, A., Williams, R., Rollins, B., Lee, E., Kar, S., Banerjee, R., Fraser, H.L.: Rapid characterization of titanium microstructural features for specific modelling of mechanical properties. Meas. Sci. Technol. 16, 60 (2004)

Belhadjsalah, H., Dogui, A., Khalfallah, A., Znaidi, A., Sidoroff, F.: Constitutive parameters identification for elastoplastic materials in finite deformation. J. Phys. IV (Proc.) 105, 3–10 (2003)

Znaidi, A., Daghfas, O., Gahbiche, A., et al.: Identification strategy of anisotropic behavior laws: application to thin sheets of A5. J. Theor. Appl. Mech. 54, 1147–1156 (2016)

Daghfas, O., Znaidi, A., Ben Mohamed, A., et al.: Experimental study on mechanical properties of aluminum alloy under uniaxial tensile test. Int. J. Technol. 4, 662–672 (2017)

Olfa, D., Amna, Z., Amen, G., Rachid, N.: Identification of the anisotropic behavior of an aluminum alloy subjected to simple and cyclic shear tests. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 233(3), 095440621876294 (2018)

Znaidi, A., Daghfas, O., Toussaint, F., Nasri, R.: Strategy for the identification of anisotropic behavior laws for Ti40 sheets. AMPT2015, Madrid (2015)

Plunkett, B., Cazacu, O., Barlat, F.: Orthotropic yield criteria for description of the anisotropy in tension and compression of sheet metals. Int. J. Plast 24(5), 847–866 (2008)

Cazacu, O., Barlat, F.: A criterion for description of anisotropy and yield differential effects in pressure-insensitive metals r. Int. J. Plast. 20(11), 2027–2045 (2004). https://doi.org/10.1016/j.ijplas.2003.11.021

Cazacu, O., Plunkett, B., Barlat, F.: Orthotropic yield criterion for hexagonal close packed metals. Int. J. Plast. 22, 1171–1194 (2006)

Jiang, S., Jiang, Z., Chen, Q.: Deformation twinning mechanism in hexagonal-close-packed crystals. Sci. Rep. (2019). https://doi.org/10.1038/s41598-018-37067

Mills, M.J., Neeraj, T.: Dislocations in Metals and Metallic Alloys Ohio State University, Columbus, Ohio, USA. Available online 1 January 2003. Encyclopedia of Materials, Science and Technology (2 edn) pp. 2278–2291 (2001)

Harbaoui, R., Znaidi, A., Nasri, R.: Modeling of titanium alloys by an identification strategy: biomechanical application. Revue des Composites et des Matériaux Avancés 27(1–2), 73–86 (2017). https://doi.org/10.3166/rcma.2017.00005

Manopulo, N., Raemy, C., Hora, P.: On the modelling of strength differential and anisotropy exhibited by titanium. J. Phys Conf. Ser. 734(3), 032051 (2016). https://doi.org/10.1088/1742-6596/734/3/032051. August

Kurukuri, S., Worswick, M.: Modeling of strength differential effects in HCP sheet materials. In: Conference: ASME 2014 International Manufacturing Science and Engineering. American Manufacturing Research Conference, June (2014). https://doi.org/10.1115/MSEC2014-4134

Zhang, K., Badreddine, H., Labergere, C., Saanouni, K.: Modeling of anisotropic and asymmetric behavior of magnesium alloys at elevated temperature coupled with ductile damage. J. Phys. Conf. Ser. 896, 0120 (2017)

Barlat, F., Brem, D.L.J.: A six components yield function for anisotropic materials. Int. J. Plast. 7, 693–712 (1991)

Revil-Baudard, B., Massonieri, E.: Simulation du comportement mécanique des alliages de titane pour les procédés de mise en forme à froid. Mécanique & Ind. 11(3–4), 265–270 (2010)

Tuninetti, V., GillesO, G., Habraken, M.A.: Anisotropy and tension-compression asymmetry modeling of the room temperature plastic response of Ti–6Al–4V. Int. J.Plast. 67, 53–68 (2015). https://doi.org/10.1016/j.ijplas.2014.10.003

Tuninetti, V., Habraken, A.: Impact of anisotropy and viscosity to model the mechanical behavior of Ti–6Al–4V alloy. May Mate. Sci. Eng. A 605, 39–50 (2014). https://doi.org/10.1016/j.msea.2014.03.009

Gilles, G., Habraken, A., Duchêne, L.: Experimental investigation and phenomenological modeling of the quasi-static mechanical behavior of TA6V titanium alloy. Sept. Key Eng. Mater. 622–623, 1200–1206 (2014). https://doi.org/10.4028/www.scientific.net/KEM.622-623.1200

Luo, S., Castany, P., Thuillier, S., Huot, M.: Spatiotemporal characteristics of portevin-le chatelier effect in Ti–Mo alloys under thermo-mechanical loading. Mater. Sci. Eng. A 733(22), 137–143 (2018)

Olfa, D.: Comportement anisotropes des alliages aluminium-des essais complexes, éditions universitaires européennes. Ph.D. Thesis in Mechanical Engineering, ISBN: 6138441249 (2018)

Mochinko, A.: Multiscale investigation of room-temperature viscoplasticity and sustained load cracking of Titanium. Influence of hydrogen and oxygen content. Ph.D. Thesis in Mechanical Engineering, https://pastel.archives-ouvertes.fr/tel-01285515 (2015)

Wang, T., Li, B., Wang, Z., Nie, Z.: Formation mechanism of the high speed deformation characteristic miscrostructure based on dislocation slipping and twinning in alpha Ti. J. Mater. Res. 31(24), 3907–3918 (2016)

Mower, T.M.: Degradation of titanium 6Al–4V fatigue strength due to electrical discharge machining. Int. J. Fatigue 64, 84–96 (2014)

Marchenko, A., Maziere, M., Forest, S., Strudel, J.-L.: Crystal plasticity simulation of strain aging phenomena in a-titanium at room temperature. Int. J. Plast. 85, 1–33 (2016)

Konovalenko, I., Maruschak, P., Prentkovskis, O.: Automated method for fractographic analysis of shape and size of dimples on fracture surface of high-strength titanium alloys. Metals 8(3), 161 (2018)

Madhukar, S., Sai, V.P., Kumar, S., Prakash, D.J.: Experimental investigation on effect of heat treatment on mechanical properties of steels and titanium. Int. J. Curr Eng. Technol. 7(3), 111–1112 (2017)

Dyakonov, G.S., Mironov, S., Enikeev, N., Valiev, R.Z., Semiatin, S.L.: Annealing behavior of severly deformed titanium grade 4. Mater. Sci. Eng. A 742(89–101), p13 (2019)

Hector Louis, G., Zavattieri, P.D.: Nucleation and propagation of portevin-Le Châtelier bands in austenitic steel with twinning induced plasticity. Expe. Appl. Mech. 6, 855–863 (2010)

Konovalenko, I., Maruschak, P., Prentkovskis, O.: Automated method for fractographic analysis of shape and size of dimples on fracture surface of high-strength titanium alloys. Metals Metall. J. 8(3), 161 (2018)

Bassoli, E., Denti, L.: Assay of secondary anisotropy in additively manufactured alloys for dental applications. Materials 11(10), 1–7 (2018)

Abbassi, F., Belhadj, T., Mistou b, S., Zghal, A.: Parameter identification of a mechanical ductile damage using artificial neural networks in sheet metal forming. Mater. Des. 45, 605–615 (2012)

Gilles, G., Habraken, A.M., Duchêne, L.: Experimental Investigation and Phenomenological Modeling of the Quasi-Static Mechanical Behavior of TA6V Titanium Alloy. Key Engineering Materials, vol. 622-623. Trans Tech Publications Ltd., Zurich (2014)

Bron, F.: Ductile tearing thin 2024 aluminum alloy sheets for aeronautical application. Ph.D. Thesis, National School of Mines of Paris (2004)

Hollomon, J.H.: Tensile deformation. Trans AIME 162, 268–290 (1945)

Voce, E.: The relationship between stress and strain for homogeneous deformations. J. Inst. Metals 74, 537–562 (1948)

Swift, H.W.: Plastic instability under plane stress. J. Mech. Phys. Solids 1(1), 1–18 (1952)

Ludwik, P.: Applied Mechanik: elemente der technologischen mechanik. Springer, Berlin (1909)

Acknowledgements

The authors gratefully acknowledge the members of the LASMIS Laboratory at UTT (University of Technology of Troyes) and LNIO laboratory for mechanical tests and SEM observations

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rym, H., Olfa, D. & Amna, Z. Strategy for identification of HCP structure materials: study of Ti–6Al–4V under tensile and compressive load conditions. Arch Appl Mech 90, 1685–1703 (2020). https://doi.org/10.1007/s00419-020-01690-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-020-01690-7