Abstract

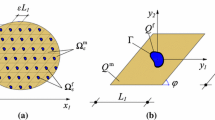

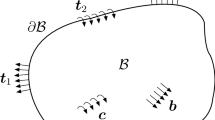

The paper presents the process of homogenization of the composite material properties obtained by method of continuous source functions developed for simulation both elasticity and heat conduction in composite material reinforced by finite-length regularly distributed, parallel, overlapping fibres. The interaction (fibre–fibre, fibre–matrix) of physical micro-fields influences the composite behaviour. Comparing with finite element method (FEM), the interaction can be simulated either by very fine FE mesh or the interaction is smoothed. The presented computational method is a mesh-reducing boundary meshless type method. The increase in computational efficiency is obtained by use of parallel MATLAB in presented computational models. The stiffness/conductivity is incrementally reduced starting with superconductive/rigid material properties of fibres and the fibre–matrix interface boundary conditions are satisfied by the iterative procedure. The computational examples presented in paper show the homogenized properties of finite-length fibre composites; the thermal and elasticity behaviour of the finite-length fibre composites; the similarities and differences in composite behaviour in thermal and elasticity problems; the control volume element for homogenization of composite materials reinforced by finite-length fibres with the large aspect ratio (length/diameter). The behaviour of the finite-length fibre composite will be shown in similar the heat conduction and elasticity problems. Moreover, the paper provides the possibilities and difficulties connected with present numerical models and suggested ways for further developments.

Similar content being viewed by others

References

Agarwal, B.D., Broutman, L.J., Chandrashekhara, K.: Analysis and Performance of Fibre Composites. Wiley, Hoboken (2006)

Schmauder, S., Weber, U.: Modelling of functionally graded materials by numerical homogenization. Arch. Appl. Mech. 71(2), 182–192 (2001)

Kamiński, M.: Material sensitivity analysis in homogenization of linear elastic composites. Arch. Appl. Mech. 71(10), 679–694 (2001)

Spring, D.W., Paulino, G.H.: Computational homogenization of the debonding of particle reinforced composites: the role of interphases in interfaces. Comput. Mater. Sci. 109, 209–224 (2015)

Hosseini Kordkheili, S., Toozandehjani, H.: Effective mechanical properties of unidirectional composites in the presence of imperfect interface. Arch. Appl. Mech. 84(6), 807–819 (2014)

Yang, Q.S., Qin, Q.H.: Fibre interactions and effective elasto-plastic properties of short-fibre composites. Compos. Struct. 54(4), 523–528 (2001)

Ghosh, S., Lee, K., Raghavan, P.: A multi-level computational model for multi-scale damage analysis in composite and porous materials. Int. J. Solids Struct. 38(14), 2335–2385 (2001)

Kompiš, V., Murčinková, Z., Žmindák, M.: Toughening mechanisms for the fibre of middle-large aspect-ratio reinforced composites. In: Qin Q.H. and Ye, J. (eds.) Toughening Mechanisms in Composite Materials, Elsevier, Woodhead Publishing, Cambridge, pp. 137–159 (2015)

Greengard, L., Rokhlin, V.: A fast algorithm for particle simulations. J. Comput. Phys. 73(2), 325–348 (1987)

Liu, Y.J., Nishimura, N., Otani, Y., Takahashi, T., Chen, X.L., Munakata, H.: A fast boundary element method for the analysis of fibre-reinforced composites based on a rigid-inclusion model. J. Appl. Mech. 72(1), 115–128 (2005)

Nishimura, N., Yoshida, K.I., Kobayashi, S.: A fast multipole boundary integral equation method for crack problems in 3D. Eng Anal Bound Elem 23(1), 97–105 (1999)

Mukherjee, S.: The boundary contour method. In: Kompiš, V. (ed.) Selected Topics in Boundary Integral Formulations for Solids and Fluids, pp. 117–150. Springer, Wien (2002)

Rjasanow, S., Steinbach, O.: The Fast Solution of Boundary Integral Equations. Springer, Berlin (2007)

Wang, H., Qin, Q.H.: A meshless method for generalized linear or nonlinear Poisson-type problems. Eng Anal Bound Elem 30(6), 515–521 (2006)

Golberg, M.A., Chen, C.S.: The method of fundamental solutions for potential, Helmholtz and diffusion problems. In: Boundary Integral Methods-Numerical and Mathematical Aspects, pp. 103–176 (1998)

Ma, H., Zhou, J., Qin, Q.H.: Boundary point method for linear elasticity using constant and quadratic moving elements. Adv. Eng. Softw. 41(3), 480–488 (2010)

Kompiš, V., Štiavnický, M., Žmindák, M., Murčinková, Z.: Trefftz radial basis functions (TRBF). Comput. Assist. Mech. Eng. Sci. 15(3/4), 239–249 (2008)

Jirousek, J., Zieliński, A.P.: Survey of Trefftz-type element formulations. Comput. Struct. 63(2), 225–242 (1997)

Kompiš, V., Štiavnický, M.: Trefftz functions in FEM, BEM and meshless methods. Comput. Assist. Mech. Eng. Sci. 13(3), 417–426 (2006)

Kompiš, V., Qin, Q.H., Fu, Z.J., Chen, C.S., Droppa, P., Kelemen, M., Chen, W.: Parallel computational models for composites reinforced by CNT-fibres. Eng. Anal. Bound. Elem. 36(1), 47–52 (2012)

Kompiš, V., Kompiš, M., Kaukič, M.: Method of continuous dipoles for modeling of materials reinforced by short micro-fibres. Eng. Anal. Bound. Elem. 31(5), 416–424 (2007)

Štiavnický, M., Kompiš, V., Kaukič, M.: Global Dipole model for composite reinforced by micro/nano-particles. In: International Conference on Computational Modeling and Experiments of the Composites Materials with Micro and Nano-Structure, Liptovský Mikuláš, Slovakia, 28–31 May 2007 (2007)

Zhou, K., Hoh, H.J., Wang, X., Keer, L.M., Pang, J.H., Song, B., Wang, Q.J.: A review of recent works on inclusions. Mech. Mater. 60, 144–158 (2013)

Kompiš, V., Štiavnický, M., Kompiš, M., Murčinková, Z., Qin, Q. H.: Method of continuous source functions for modelling of matrix reinforced by finite fibres. In: Kompiš V. (ed.) Oñte, E. (series ed.) Composites with Micro-and Nano-Structure, Springer Netherlands, pp. 27–45 (2008)

Kompiš, V., Murčinková, Z., Ferencey, V.: Computational simulation of composite materials reinforced by fibres with large aspect ratio. Strojnícky časopis 63(3), 139–153 (2012)

Kompiš, V., Zuzana Murčinková, Z.: Thermal properties of short fibre composites modeled by meshless method. Advances in Materials Science and Engineering 2014, 1–8 (2014)

Kompiš, V., Murčinková, Z., Očkay, M.: Temperature fields in short fibre composites. In: Murín, J., Kompiš, V., Kutiš, V. (eds) Computational Modeling and Advanced Simulations: Computational Methods in Applied Science, pp. 99–116. Springer, Berlin (2011)

Qin, Q.H.: Introduction to the composite and its toughening mechanisms. In: Qin, Q.H., Ye, J. (eds.) Toughening Mechanisms in Composite Materials, pp. 1–32. Woodhead publishing Elsevier, Amsterdam (2015)

Kanit, T., Forest, S., Galliet, I., Mounoury, V., Jeulin, D.: Determination of the size of the representative volume element for random composites: statistical and numerical approach. Int. J. Solids Struct. 40(13), 3647–3679 (2003)

Xia, Z., Zhang, Y., Ellyin, F.: A unified periodical boundary conditions for representative volume elements of composites and applications. Int. J. Solids Struct. 40(8), 1907–1921 (2003)

Materials and Processes (Chapter 2) (2002) The Effects of Variability on Composite Properties, Composite Material Handbook, Vol. 3. Polymer Matrix Composites Materials Usage, Design and Analysis. Department of Defense USA, MIL-HDBK-17-3F

Decolon, C.: Analysis of Composite Structures. Butterworth-Heinemann, Oxford (2004)

Acknowledgements

The first of authors thank for supporting this research by grant VEGA 1/0910/17 and 1/0983/15 of Agency of Ministry of Education of Slovak Republic.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Rights and permissions

About this article

Cite this article

Murčinková, Z., Novák, P., Kompiš, V. et al. Homogenization of the finite-length fibre composite materials by boundary meshless type method. Arch Appl Mech 88, 789–804 (2018). https://doi.org/10.1007/s00419-018-1342-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-018-1342-5