Abstract

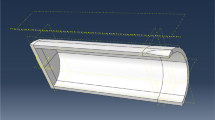

Failure mechanisms such as local cavitation observed in crystalline thermoplastics pipes submitted to low constant pressure are likely to be induced by microstructure heterogeneity and time-dependent macroscopic stress fields. This study on poly(vinylidene) fluoride (PVDF) focuses on the latter, simulating the long-term creep behavior of homogeneous viscous pipes with finite-element calculations. Stress and strain distributions are evaluated just after loading and their evolution with time is considered. The hydrostatic stress is analyzed in relation to the onset of cavitation. The detrimental consequences of thickness defects due to extrusion on the onset of cavitation are also established.

Similar content being viewed by others

References

Brown N., Lu X. et al. (1991). Slow crack growth in polyethylene – a review. Makromol. Chemei, Macromol. Symp. 41:55–67

Lu X., Brown N. (1992). A test for slow crack growth failure in polyethylene under a constant load. Polym. Testing 11:309–319

Rose L.J., Channell A.D., Frye C.J., Capaccio G. (1994). Slow crack growth in polyethylene: a novel predictive model based on the creep of craze fibrils. J. Appl. Polym. Sci. 54:2119–2124

Plummer C.J.G., Goldberg A. et al. (2001). Micromechanisms of slow crack growth in polyethylene under constant tensile loading. Polymer 42:9551–9564

Brown N., Huang Y.L. et al. (1992). The fundamental material parameters that govern slow crack growth in linear polyethylenes. Plast. Rubber Compos. Process. Appl. 17:255–258

Barry D.B., Delatycki O. (1992). The effect of molecular structure and polymer morphology on the fracture resistance of high density polyethylene. Polymer 33:1261–1265

Challier M., Besson J. et al. (2006). Damage and fracture of polyvinylidene fluoride (PVDF) at 20°C: experiments and modelling. Eng. Fract. Mech. 73:79–90

Castagnet, S., Deburck, Y., to be published in Polym. Eng. Sci.

Hamouda H.B.H., Simoes-Betbeder M. et al.(2001). Creep damage mechanisms in polyethylene gas pipes. Polymer 42:5425–5437

Gacougnolle J.L., Castagnet S., Werth M. (2006). Post-mortem analysis of failure in PolyVinylidene Fluoride pipes tested under constant pressure in the slow crack growth regime. Eng. Fail. An. 13:96–109

Reddy D.V., Ataoglu S. (2004). Analysis of jointed HDPE pipe. J. Adv. Mater. 36:43–50

Popelar C.H., Evans D. (2004). Creep ovalization and buckling of a linear viscoelastic externally pressurized pipe. J. Press. Vessel Technol. 126:208–215

Chuntao Zhang I.D., Moore I.D. (1998). Nonlinear finite element analysis for thermoplastic pipes. Transp. Res. Rec. 1624:225–230

Farshad M., Flueler P. (1996). Buckling resistance of polymer pipes under hydrostatic pressure. Plast. Rubber Compos. Process. Appl. 25:373–379

Dhar A.S., Moore I.D., McGrath T.J. (2004). Two-dimensional analyses of thermoplastics culvert deformations and strains. J. Geoenviron. Eng. 130:199–208

Schafer B.W., McGrath T.J. (2003). Buried corrugated thermoplastic pipe. Transp. Res. Rec. 1849:135–141

Dhar A.S., Moore I.D. (2002). Corrugated high-density polyethylene pipe; laboratory testing and two-dimensional analysis to develop limit states design. Transp. Res. Rec. 1814:157–163

Reddy D.V., Ahn W.S., Ataoglu S. (2004). Investigation of flexural creep for high density polyethylene pipe. J. Adv. Mater. 36:18–24

Gent A.N., Lindley P.B. (1959). Internal rupture of bonded rubber cylinders in tension. Proc. R. Soc. Lond. A. 249:195–205

Horgan C.O., Abeyaratne R. (1986). A bifurcation problem for a compressible nonlinearly elastic medium: growth of a micro-void. J. Elasticity 16:189–200

Fond C., Lobbrecht A., Schirrer R. (1996). Polymers thoughened with rubber microspheres; an analytical solution for stresses and strains in the rubber particles at equilibrium and rupture. Int. J. Fract. 77:141–159

Castagnet S., Girault S., Gacougnolle J.L., Dang P. (2000). Cavitation in strained PVDF: mechanical and X-Rays experimental studies. Polymer 41:7523–7530

André-Castagnet S., Tencé-Girault S. (2002). Relationships between mechanical tensile behaviour and micromechanisms in poly(vinylidene fluoride) at high temperatures: influence of the molecular weight distribution. J. Macromol. Sci. B41:957–976

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Castagnet, S., Grandidier, J.C. Structural effect in the creep behavior of thermoplastic pressure pipes at high temperature – role of geometrical defects. Arch Appl Mech 76, 567–578 (2006). https://doi.org/10.1007/s00419-006-0070-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-006-0070-4