Abstract

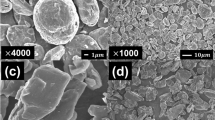

Understanding and controlling the rheology of electrode slurries for lithium-ion batteries is critical both for improving their manufacturing efficiency and for achieving desirable battery performance. Here, we show drastic “slurry-preparation-dependent” rheology in an anode slurry for lithium-ion batteries, focusing on the behaviour of carboxymethyl cellulose (CMC), which is the most popular dispersant for graphite particles in anode slurries. Slurry preparation with dry-state mixing, where water is added to a dry mixture of graphite and CMC powder, results in much higher viscosity, yield stress, and elastic modulus than those achieved with conventional wet-state mixing, where graphite is added to a CMC solution. Cryogenic scanning electron microscopy reveals strange CMC “clumps” formed among the graphite particles in the slurry prepared with dry-state mixing. We attribute the increases in viscosity, yield stress, and elastic modulus for the slurries prepared with dry-state mixing to these clumps of CMC, which can enhance the adhesion between graphite particles and thereby constrain their motion. We also show that pre-shearing irreversibly decreases viscosity, yield stress, and elastic modulus, suggesting that the clumps of CMC are irreparably broken down by applied shear. The influence of the slurry preparation method on the rheological properties of anode slurries has not received attention in previous studies. Hence, we believe that our results might provide new strategies for controlling the rheology of the anode slurry in the manufacturing process for lithium-ion batteries.

Similar content being viewed by others

References

Bauer W, Nötzel D (2014) Rheological properties and stability of NMP based cathode slurries for lithium ion batteries. Ceram Int 40:4591–4598

Bérut A, Pouliquen O, Forterre Y (2019) Brownian granular flows down heaps. Phys Rev Lett 123:248005

Bockholt H, Haselrieder W, Kwade A (2013) Intensive dry and wet mixing influencing the structural and electrochemical properties of secondary lithium-ion battery cathodes. ECS Trans 50:25–35

Bockholt H, Haselrieder W, Kwade A (2016) Intensive powder mixing for dry dispersing of carbon black and its relevance for lithium-ion battery cathodes. Powder Technol 297:266–274

Caggioni M, Trappe V, Spicer PT (2020) Variations of the Herschel-Bulkley exponent reflecting contributions of the viscous continuous phase to the shear rate-dependent stress of soft glassy materials. J Rheol 64:413–422

Chang WJ, Lee GH, Cheon YJ, Kim JT, Lee SI, Kim J, Kim M, Park WI, Lee YJ (2019) Direct observation of carboxymethyl cellulose and styren-butadiene rubber binder distribution in practical graphite anodes for li-ion batteries. ACS Applied Materials & Interfaces 11:41330–41337

Gordon R, Orias R, Willenbacher N (2020) Effect of carboxymethyl cellulose on the flow behavior of lithium-ion battery anode slurries and the electrical as well as mechanical properties of corresponding dry layers. J Mater Sci 55:15867–15881

Guy BM, Hermes M, Poon WCK (2015) Towards a unified description of the rheology of hard-particle suspensions. Phys Rev Lett 115:088304

Guy BM, Richards JA, Hodgson DJM, Blanco E, Poon WCK (2018) Constraint-based approach to granular dispersion rheology. Phys Rev Lett 121:128001

Ishii M, Nakamura H (2022) Influence of molecular weight and concentration of carboxymethyl cellulose on rheological properties of concentrated anode slurries for lithium-ion batteries. JCIS Open 6:100048

Jiang Y, Makino S, Royer JR, Poon WCK (2022) Flow-switched bistability in a colloidal gel with non-brownian grains. Phys Rev Lett 128:248002

Kitamura K, Tanaka M, Mori T (2022) Effects of the mixing sequence on the graphite dispersion and resistance of lithium-ion battery anodes. J Colloid Interface Sci 625:136–144

Kumberg J, Bauer W, Schmatz J, Diehm R, Tönsmann M, Müller M, Ly K, Scharfer P, Schabel W (2021) Reduced drying time of anodes for lithium-ion batteries through simultaneous multilayer coating. Energ Technol 9:2100367

Kwon YI, Kim JD, Song YS (2014) Agitation effect on the rheological behavior of lithium-ion battery slurries. J Electron Mater 44:475–481

Larsen Th, Søbye AL, Royer JR, Poon WCK, Larsen T, Andreasen SJ, Drozdov AD, Christiansen JDC (2022) Rheology of polydisperse nonspherical graphite particles suspended in mineral oil. J Rheol 67:81–89

Lee JH, Paik U, Hackley VA, Choi YM (2005) Aqueous processing of natural graphite particulates for lithium-ion battery anodes and their electrochemical performance. J Electrochem Soc 152:A1763–A1769

Lee GW, Ryu JH, Han W, Ahn KH, Oh SM (2010) Effect of slurry preparation process on electrochemical performances of \(\rm LiCoO_2 \) composite electrode. J Power Sources 195:6049–6054

Li CC, Lin YS (2012) Interactions between organic additives and active powders inwater-based lithium iron phosphate electrode slurries. J Power Sources 220:413–421

Lim S, Kim S, Ahn KH, Lee SJ (2015) The effect of binders on the rheological properties and the microstructure formation of lithium-ion battery anode slurries. J Power Sources 299:221–230

Mari R, Seto R, Morris JF, Denn MM (2014) Shear thickening, frictionless and frictional rheologies in non-Brownian suspensions. J Rheol 58:1693–1724

Park JH, Kim SH, Ahn KH (2023) Role of carboxymethyl cellulose binder and its effect on the preparation process of anode slurries for Li-ion batteries. Colloids Surf, A 664:131130

Richards JA, Guy BM, Blanco E, Hermes M, Poy G, Poon WCK (2020) The role of friction in the yielding of adhesive non-Brownian suspensions. J Rheol 64:405–412

Richards JA, O’Neill RE, Poon WCK (2021) Turning a yield-stress calcite suspension into a shear-thickening one by tuning inter-particle friction. Rheol Acta 60:97–106

Russel WB, Saville DA, Schowalter WR (1989) Colloidal dispersion. Cambridge University Press, Cambridge

Wang M, Dang D, Meyer A, Arsenault R, Cheng YT (2020) Effects of the mixing sequence on making lithium ion battery electrodes. J Electrochem Soc 167:100518

Wyart M, Cate ME (2014) Discontinuous shear thickening without inertia in dense non-brownian suspensions. Phys Rev Lett 112:098302

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file 2 (mp4 15720 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Makino, S., Akimoto, Y., Ishii, M. et al. Impact of slurry preparation method on the rheological behaviour of dense anode slurries for lithium-ion batteries. Rheol Acta 63, 319–331 (2024). https://doi.org/10.1007/s00397-024-01440-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-024-01440-4