Abstract

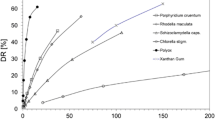

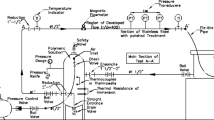

The capability of a mixture of okra fiber and mucilage as drag reducer in high Reynolds number flows through a pipeline, in which the flux is maintained by a centrifugal pump with controlled rotation, is analyzed. A DR close to the maximum drag reduction asymptote, which is obtained for polymeric additives, was achieved when concentrations around 1600 ppm were used. The loss of efficiency of the solution over the number of passes through the system was almost the same of that observed for rigid materials like Xanthan Gum and Guar Gum, which suggest that the main cause of a decreasing drag reduction is the de-aggregation instead of mechanical degradation, commonly observed in flexible polymers. As expected, the material degrades biologically, but it seems that it is not a great problem for open systems, since such a degradation is perceptible only after 24 h. We strongly believe that this new bio-drag reducer can be an alternative to synthetic polymers or other biopolymers, since it is extremely cheap and easy to be obtained.

Similar content being viewed by others

Notes

Mucilage is a thick, gluey substance produced by nearly all plants and some microorganisms. It is a polar glycoprotein, a natural polymer of high molecular weight.

References

Abdulbari HA, Ahmad MA, Yunus RBM (2010) Formulation of okra-natural mucilage as drag reducing agent in different size of galvanized iron pipes in turbulent water flowing system. J Appl Sci 23:3105–3110

Abdulbari HA, Kamarulizam SN, Man RC (2011) Investigating drag reduction characteristic using okra mucilage as new drag reduction agent. J Appl Sci:1–8

Abdulbari HA, Kamarulizam SN, Nour AH (2012) Grafted natural polymer as new drag reducing agent: an experimental approach. Chem Ind Chem Eng Q 18:361–371

Abdulbari HA, Shabirin A, Abdurrahman HN (2014) Bio-polymers for improving liquid flow in pipelines—a review and future work opportunities. J Ind Eng Chem 20:1157–1170

Andrade RM, Pereira AS, Soares EJ (2014) Drag increase at the very start of drag reducing flows in a rotating cylindrical double gap device. J Non-Newtonian Fluid Mech 212:73–79

Andrade RM, Pereira AS, Soares EJ (2016) Drag reduction in synthetic seawater by flexible and rigid polymer addition into a rotating cylindrical double gap device. ASME-Journal of Fluids Eng 138:021101

Bewersdorff HW, Singh RP (1988) Rheological and drag reduction characteristics of xanthan gum solutions. Rheol Acta 27:617– 627

Candlish JK, Gourley L, Lee HP (1987) Dietary fiber and starch contents of some southeast asian vegetables. J Agric Food Chem 35:319–321

Chen X, Zha D, Xiu J, Liao Y, Cui K, Lin H, Jian Z, Hu F, Huang X, Zhou B, Huang Q, Bin J, Liu Y (2011) A new hydrodynamic approach by infusion of drag-reducing polymers to improve left ventricular function in rats with myocardial infarction. Int J Cardiol 147:112–117

Choi HJ, Jhon MS (1996) Polymer-induced turbulent drag reduction. Ind Eng Chem Res 35:2993–2998

Dimitropoulos CD, Dubief Y, Shaqfeh ESG, Moin P, Lele SK (2005) Direct numerical simulation of polymer-induced drag reduction in turbulent boundary layer flow. Phys Fluids 17:1–4

Forrest F, Grierson GA (1931) Friction losses in cast iron pipe carrying paper stock. Paper Trade J 92:39–41

Freitas JCC, Cunha AG, Emmerich FG (2012) Chemistry and physics of carbon, vol 31. CRC press, Ch. Solid-state nuclear magnetic resonance (NMR) methods applied to the study of carbon materials, pp 85–170

Huang Z, Chen Z, Li Q, Zhu R, Jing S, Zhou R, Ma Y, Wang N, Chang W (2014) Experimental research on the drag reduction mechanism of natural gas drag reduction agent and its industrial field test. Ind Eng Chem Res 53:12494–12501

Jaafar A, Poole R (2011)

Kameneva MV (2012) Microrheological effects of drag-reducing polymers in vitro and in vivo. Int J Eng Sci 59:168–183

Little R, Smidt S, Huang P, Romans J, Dedrick J, Matuszko JS (1991) Improved drag reduction by control of polymer particle size. Ind Eng Chem Res 30:403–407

Lumley JL (1969) Drag reduction by additives. Ann Rev Fluid Mech 11:367–384

MacKenzie KJD, Smith ME (2002) Multinuclear solid-state NMR of inorganic materials. Pergamon, Amsterdan

Merrill EW, Horn AF (1984) Scission of macromelecules in dilute solution: extensional and turbulent flows. Polymer Communications 25:144–146

Mohsenipour AA, Pal R (2013) The role of surfactants in mechanical degradation of drag-reducing polymers. Ind Eng Chem Res 52:1291–1302

Morris ER (1977) Molecular origin of xanthan solution properties. Extracellular microbial polysaccharides. ACS Symp Ser 45:81– 89

Moussa T, Tiu C (1994) Factors affecting polymer degradation in turbulent pipe flow. Chem Eng Sci 49:1681–1692

Muller G, Anrhourrache M, Lecourtier J, Chauveteau G (1986) Salt dependence of the conformation of a single-stranded xanthan. Int J Biol Macromol 8:167–172

Mysels KJ (1949) Flow of thickened fluids. U.S. Patent 2 Dec. 27 492, p 173

Myska J, Zakin JL (1997) Differences in the flow behaviors of polymeric and cationic surfactant drag-reducing additives. Ind Eng Chem Res 36:5483–5487

O’Donnell JK, Ackerman JH, Maciel GE (1981) Comparative study of whole seed protein and starch content via cross polarization-magic angle spinning carbon-13 nuclear magnetic resonance spectroscopy. J Agric Food Chem 29:514–518

Ogata S, Gunawan, Warashina J, Yanuar (2014) Drag reduction of a pipe flow using nata de coco suspensions. Adv Mech Eng

Pereira AS, Soares EJ (2012) Polymer degradation of dilute solutions in turbulent drag reducing flows in a cylindrical double gap rheometer device. J Non-Newtonian Fluid Mech 179:9–22

Pereira AS, Andrade RM, Soares EJ (2013) Drag reduction induced by flexible and rigid molecules in a turbulent flow into a rotating cylindrical double gap device: comparison between poly (ethylene oxide), polyacrylamide, and xanthan gum. J Non-Newtonian Fluid Mech 202:72–87

Phukan S, Kumar P, Panda J, Nayak BR, Tiwari KN, Singh RP (2001) Application of drag reducing commercial and purified guar gum for reduction of energy requirement of sprinkler irrigation and percolation rate of the soil. Agric Water Manag 47:101–118

Sandoval GAB, Soares EJ (2016) Effect of combined polymers on the loss of efficiency caused by mechanical degradation in drag reducing flows through straight tubes. Rheologica Acta

Singh HKG, Jaafar A, Yusup S (2014) The effect of sodium hydroxide on drag reduction using a biopolymer. MATEC Web of Conferences:13

Soares EJ, Sandoval GAB, Silveira L, Pereira AS, Trevelin R, Thomaz F (2015) Loss of efficiency of polymeric drag reducers induced by high Reynolds number flows in tubes with imposed pressure. Phys Fluids 27:125105–1–125105–23

Soares EJ, Siqueira RN, Coelho EC, Barbosa KCO (2016) Bio-redutor de arrasto a base de mucilagem e fibra de quiabo para escoamentos turbulentos em dutos. Patent BR 10 2016 013995 3. Universidade Federal do Espírito Santo

Tabor M, de Gennes PG (1986) A cascade theory of drag reduction. Europhys Lett 2:519–522

Toms BA (1948) Some observations on the flow of linear polymer solutions through straight tubes at large reynolds numbers. In: Proceedings of the international congress of rheology. Section II, North-Holland, pp 135–141

Virk PS (1975) Drag reduction fundamentals. AIChE J 21:625–656

White CM, Mungal MG (2008) Mechanics and prediction of turbulent drag reduction whit polymer additives. Ann Rev Fluid Mech 40:235–256

Wyatt NB, Gunther CM, Liberatore MW (2011) Drag reduction effectiveness of dilute and entangled xanthan in turbulent pipe flow. J Non-Newtonian Fluid Mech 166:25–31

Acknowledgments

This research was partially funded by grants from CNPq (Conselho Nacional de Pesquisa e Desenvolvimento), ANP (Agência Nacional de Petróleo) and PETROBRAS.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Coelho, E.C., Barbosa, K.C.O., Soares, E.J. et al. Okra as a drag reducer for high Reynolds numbers water flows. Rheol Acta 55, 983–991 (2016). https://doi.org/10.1007/s00397-016-0974-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-016-0974-z