Abstract

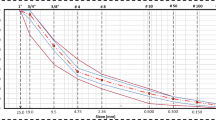

Most adhesives and binders, including bitumen for asphalt mixture production, are presently produced from petrochemicals after the refining of crude oil. The fact that crude oil reserves are a finite resource means that in the future, it may become necessary to produce these materials from alternative and probably renewable sources. Suitable resources of this kind may include polysaccharides, plant oils and proteins. This paper deals with the synthesis of polymer binders from monomers that could, in future, be derived from renewable resources. These binders consist of polyethyl acrylate (PEA) of different molecular weight, polymethyl acrylate (PMA) and polybutyl acrylate (PBA), which were synthesised from ethyl acrylate, methyl acrylate and butyl acrylate, respectively, by atom transfer radical polymerisation. The rheological properties of these binders were determined by means of oscillatory testing using a dynamic shear rheometer and combinations of stress/strain, temperature and frequency sweeps. The results indicate that PEA can be produced to have rheological properties similar to that of ‘soft’ 100/150 penetration grade bitumen, PMA with similar rheological properties to that of ‘hard’ 10/20 penetration grade bitumen, while PBA, due to its highly viscous nature and low dynamic moduli, cannot be used on its own as a binder. The synthetic polymers were found to be thermo-rheologically simple, and the shift factors, used to produce the dynamic moduli master curves, were found to fit an Arrhenius function.

Similar content being viewed by others

References

Airey GD (2002a) Use of black diagrams to identify inconsistencies in rheological data. Road Mater Pavement Des 3:403–424

Airey GD (2002b) Rheological evaluation of ethylene vinyl acetate polymer modified bitumens. Constr Build Mater 16:473–487

Airey GD (2003) Rheological properties of styrene butadiene styrene modified road bitumens. Fuel 82:1709–1719

Airey GD, Brown SF (1998) Rheological performance of aged polymer modified bitumens. Assoc Asphalt Tech 67:66–100

Airey GD, Hunter AE (2003) Dynamic mechanical testing of bitumen—sample preparation methods. ICE Transport 156:85–92

Airey GD, Rahimzadeh B, Collop AC (2002) Linear viscoelastic limits of bituminous binders. Assoc Asphalt Tech 71:89–115

Ahmad S, Haque MM, Ashraf SM, Ahmad S (2004) Urethane modified boron filled polyesteramide: a novel anti-microbial polymer from a sustainable resource. Eur Polym J 40:2097–2104

Anderson DA, Christensen DW, Bahia HU, Dongre R, Sharma MG, Antle CE, Button J (1994) Binder characterisation, vol 3: physical properties, SHRP-A-369. National Research Council, Washington, DC

ASTM (1986) Standard test method for viscosity of asphalt with cone and plate viscometer. ASTM D 3205-77. Annu Book ASTM Stand 4.03:468–472

Barnes HA, Hutton JF, Walters K (1989) An introduction to rheology. Elsevier, Amsterdam

Christensen DW, Anderson DA (1992) Interpretation of dynamic mechanical test data for paving grade asphalt cements. Assoc Asphalt Tech 61:67–116

Daga VK, Wagner NJ (2006) Linear viscoelastic master curves of neat and laponite-filled poly(ethylene oxide)–water solutions. Rheol Acta 45:813–824

Dickinson EJ, Witt HP (1974) The dynamic shear modulus of paving asphalts as a function of frequency. Trans Soc Rheol 18:591–605

Emengo FN, Chukwu SER, Mozie J (2002) Tack and bonding strength of carbohydrate-based adhesives from different botanical sources. Int J Adhes Adhes 22:93–100

Ferry JD (1980) Viscoelastic properties of polymers. Wiley, New York

Gaw WJ (1978) The measurement and prediction of asphalt stiffness at low and intermediate pavement service temperatures. Assoc Asphalt Tech 47:457–494

Goodrich JL (1988) Asphalt and polymer modified asphalt properties related to the performance of asphaltic concrete mixes. Assoc Asphalt Tech 57:116–175

Goodrich JL (1991) Asphaltic binder rheology, asphalt concrete rheology and asphalt concrete mix properties. Assoc Asphalt Tech 60:80–120

Griffen RL, Miles TK, Penther CJ, Simpson WC (1956) Sliding plate microviscometer for rapid measurements of asphalt viscosity in absolute units. ASTM Special Technical Publication 212:36

Kaplan DL (1998) Biopolymers from renewable resources. Springer, Berlin, pp 1–3

Lesueur D, Gerard JF, Claudy P, Letoffe JM, Planche JP, Martin D (1996) A structure-related model to describe bitumen linear viscoelasticity. J Rheol 40:813–836

Marasteanu M, Anderson DA (1996) Time–temperature dependency of asphalt binders—an improved model. Assoc Asphalt Tech 65:408–448

Monismith CL, Alexander RL, Secor KE (1966) Rheological behaviour of asphalt concrete. Assoc Asphalt Tech 35:400–450

Pellinen TK, Biswas K, Rowe GM, Sharrock MJ (2003) Procedure for obtaining binder stiffness over a range of temperatures for mix stiffness predictive models. J Applied Asphalt Binder Tech 3:44–67

Petersen JC, Robertson RE, Branthaver JF, Harnsberger PM, Duvall JJ, Kim SS, Anderson DA, Christensen DW, Bahia HU, Dongre R, Sharma MG, Antle CE, Button J, Glover CJ (1994) Binder characterisation and evaluation, vol 4: test methods, SHRP-A-370. National Research Council, Washington, DC

Pink HS, Merz RE, Bosniack DS (1980) Asphalt rheology: experimental determination of dynamic moduli at low temperatures. Assoc Asphalt Tech 49:64–94

Planche JP, Lesueur D, Hines ML, King GN (1996) Evaluation of elastomer modified bitumens using SHTP binder specifications. Eurasphalt & Eurobitume Congress E&E.5.121, Strasbourg

Schweyer HE, Smith LL, Fish GW (1976) A constant stress rheometer for asphalt cements. Assoc Asphalt Tech 45:53–72

Shields J (1976) Adhesives handbook. Butterworth, London

Soenen H, De Visscher J, Vanelstraete A, Redelius P (2006) Influence of thermal history on rheological properties of various bitumen. Rheol Acta 45:729–739

Tsujimoto T, Uyama H, Kobayashi S (2004) Synthesis and curing behaviors of cross-linkable polynaphthols from renewable resources: preparation of artificial urushi. Macromolecules 37:1777–1782

Uyama H, Kuwabara M, Tsujimoto T, Kobayashi S (2003) Enzymatic synthesis and curing of biodegradable epoxide-containing polyesters from renewable resources. Biomacromolecules 4:211–215

Van der Poel C (1954) A general system describing the visco-elastic properties of bitumen and its relation to routine test data. J Appl Chem 4:221–236

Welty JR, Wicks CE, Wilson RE (1984) Fundamentals of momentum, heat and mass transfer, 3rd edn. Wiley, New York, pp 772–773

Acknowledgements

The authors would like to thank the UK Engineering and Physical Sciences Research Council (EPSRC) for supporting this research under a Platform Grant awarded to the Nottingham Transportation Engineering Centre. They would also like to acknowledge the contribution of Dr. Christopher Hayes of the School of Chemistry at the University of Nottingham through his involvement with the synthesis work described in the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Airey, G.D., Mohammed, M.H. Rheological properties of polyacrylates used as synthetic road binders. Rheol Acta 47, 751–763 (2008). https://doi.org/10.1007/s00397-007-0250-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-007-0250-3