Abstract

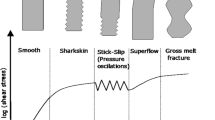

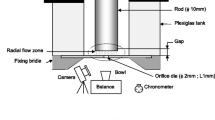

The extrusion of polymer melts is often rate limited by the onset of an elastic surface instability known as sharkskin. Appearance of these surface distortions is generally unacceptable for commercial applications. The desire to forestall the onset of sharkskin to higher output rates has motivated a considerable amount of research to characterize the nature of the instability. In this manuscript, we will present a series of detailed experiments using a custom fabricated extruder and die. By incorporating thermal breaks and precise localized temperature control of the die and barrel, predetermined temperature gradients could be induced across the extrudate. Polymers are typically very poor thermal conductors, and therefore the effects of heating or cooling from a boundary can be designed to only affect the properties of the extrudate very close to the die wall. We will present data correlating the amplitude and frequency of the sharkskin instability to the bulk and die surface temperature as well as the shear rates. The result is a quantitative processing map that characterizes the instability and demonstrates that by modifying the rheology of the polymeric fluid very near the die exit corner, it is possible to suppress or control the sharkskin instability through isolated die heating or cooling. By reformulating our data into Weissenberg and Deborah numbers using the relaxation time evaluated at the wall temperature, we demonstrate that the sharkskin surface instability is dependent only on flow kinematics and viscometric properties of the fluid very near the die wall, a result of the stress singularity present at the die exit, and independent of bulk fluid properties. This technique could conceivably increase the profitability of extrusion processes and be extended to develop precisely-controlled sharkskin for designing specific functionality into extruded surfaces.

Similar content being viewed by others

References

Barone JR, Plucktaveesak N, Wang SQ (1998) Interfacial molecular instability mechanism for sharkskin phenomenon in capillary extrusion of linear polyethylenes. J Rheol 42:813–832

Bertola V, Meulenbroek B, Wagner C, Storm C, Morozov A, Saarloos Wv, Bonn D (2003) Experimental evidence for an intrinsic route to polymer melt fracture phenomena: A nonlinear instability of viscoelastic Poiseuille flow. Phys Rev Lett 90:114502(4)

Bird RB, Armstrong BC, Hassager O (1987) Dynamics of polymeric liquids: Vol 1: Fluid mechanics. Wiley, New York

Chung CI (2000) Extrusion of polymers: theory and practice. Carl Hanser, Munich, Germany

Cogswell FN (1976) A method for reducing sharkskin on extruded polymeric material. British Patent #1 441 586

Cogswell FN (1977) Stretching flow instabilities at the exits of extrusion dies. J Non-Newton Fluid 2:37–47

Coppeta J, Rogers C (1998) Dual emission laser induced fluorescence for direct planar scalar behavior measurements. Exp Fluids 25:1-15

Denn MM (2001) Extrusion instabilities and wall slip. Annu Rev Fluid Mech 33:265–287

Dhori PK, Jeyaseelan RS, Giacomin AJ, Slattery JC (1997) Common line motion III: implication in polymer extrusion. J Non-Newton Fluid 71:231–243

El Kissi N, Piau J-M (1994) Adhesion of linear low density polyethylene for flow regimes with sharkskin. J. Rheol 38:1447–1463

Ghanta VG, Riise BL, Denn MM (1998) Disappearance of extrusion instabilities in brass capillary dies. J Rheol 43:435–442

Howells ER, Benbow JJ (1962) Flow defects in polymer melts. T J Plast I 30:240–253

Inn YW, Fisher RJ, Shaw MT (1998) Visual observation of development of sharkskin melt fracture in polybutadiene extrusion. Rheol Acta 37:573–582

Iooss G, Joseph D (1980) Elementary stability and bifurcation theory. Springer, Berlin Heidelberg New York

Kalika DS, Denn MM (1987) Wall slip and extrudate distortion in linear low-density polyethylene. J Rheol 31:815–834

Larson RG (1992) Instabilities in viscoelastic flows. Rheol Acta 31:213–263

Mackley M, Rutgers R, Gilbert D (1998) Surface instabilities during the extrusion of linear low density polyethylene. J Non-Newton Fluid 76:281–297

Meulenbroek B, Storm C, Bertola V, Wagner C, Bonn D, Saarloos Wv (2003) Intrinsic route to melt fracture in polymer extrusion: A weakly nonlinear subcritical instability in viscoelastic Poiseuille flow. Phys Rev Lett 90:024502(4)

Mhetar V, Archer LA (1998) Slip in entangled polymer melts. 1. General features. Macromolecules 31:8607–8616

Michaeli W (1984) Extrusion dies: design and engineering computations. Carl Hanser/Macmillan, Munich, Germany

Migler KB, Lavalee C, Dillon MP, Woods SS, Gettinger CL (2001) Visualizing the elimination of sharkskin through fluoropolymer additives: Coating and polymer-polymer slippage. J Rheol 45:565–581

Morrison FA (2001) Understanding rheology. Oxford University Press, New York

Perez-Gonzalez J, Denn MM (2001) Flow enhancement in the continuous extrustion of linear low-density polyethylene. Ind Eng Chem Res 40:4309–4316

Petrie CJS, Denn MM (1976) Instabilites in polymer processing. AIChE J 22:209–236

Piau JM, El Kissi N, Tremblay B (1989) Influence of upstream instabilities and wall slip on melt fracture and sharkskin phenomena during silicones extrusion through orifice dies. J Non-Newton Fluid 34:145–180

Piau J-M, Kissi NE, Toussant F, Mezghani A (1995) Distortion of polymer melt extrudates and their elimination using slippery surfaces. Rheol Acta 34:40–57

Pudjijanto S, Denn MM (1994) A stable “island” in the slip-stick region of linear low-density polyethylene. J Rheol 38:1735–1744

Ramamurthy AV (1986) Wall slip in viscous fluids and influence of materials of construction. J Rheol 30:337–357

Rothstein JP, McKinley GH (1999) Extensional flow of a polystyrene Boger fluid through a 4:1:4 axisymmetric contraction/expansion. J Non-Newton Fluid 86:61–88

Rutgers R, Clemeur N, Husny J (2002) The prediction of sharkskin instability observed during film blowing. Int Polym Proc 17:214–222

Santamaria A, Fernandez M, Sanz E, Lafuente P, Munoz-Escalona A (2003) Postponing sharkskin of metallocene polyethylenes at low temperatures: the effect of molecular parameters. Polymer 44:2473–2480

Tordella JP (1963) Unstable flow of molten polymers: A second site of melt fracture. J Appl Polym Sci 7:215–229

Touloukian YS (1979) Thermophysical properties of matter; the TPRC data series. IFI/Plenum, New York

Winter HH (1977) Viscous dissipation in shear flows of molten polymers. Adv Heat Transfer 13:205–267

Acknowledgements

The authors would like to acknowledge the Executive Area for Research for partial support of this research through a Healy Endowment Grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miller, E., Rothstein, J.P. Control of the sharkskin instability in the extrusion of polymer melts using induced temperature gradients. Rheol Acta 44, 160–173 (2004). https://doi.org/10.1007/s00397-004-0393-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-004-0393-4