Abstract

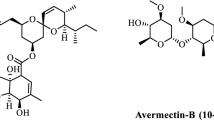

Pickering emulsion stabilized by lignin/sodium dodecyl sulfate composite nanoparticles (LSNP) was used as template to prepare the avermectin @ lignin/polyurea composite microcapsules (AVM@LPMC) through ion cross-linking and interfacial polymerization. The inner wall of the microcapsules is a firm and compact polyurea layer, and the outer wall is a loose lignin layer. The effects of stirring speed, dosage of sodium dodecyl sulfate (SDS), and pH value in aqueous phase on the formation of microcapsules were systematically studied. The results showed that the optimal stirring speed was 200 rpm, and the optimal dosage ratio in water phase was HCl (mmol):SDS (mmol):lignin AL (g) = 0.375:1.25:1 in fixed oil-water ratio (1:9) and oil phase composition. In this way, the encapsulation efficiency of microcapsules could reach up to 85.4%, while it would slightly decrease with the increase of lignin content in the wall materials. The polyurea layer played a key role in supporting the spherical structure of the capsule wall and delaying the release of avermectin, while the loose lignin layer contributed less to the slow release performance of microcapsule. By changing the amount of lignin, the polyurea-layer thickness could be regulated to adjust the release rate of microcapsule. Remarkably, a small amount of lignin introduced in the wall material could significantly improve the anti-photolysis performance of avermectin in microcapsules.

Similar content being viewed by others

References

Poe SL, Kobašlija M, McQuade DT (2007) Mechanism and application of a microcapsule enabled multicatalyst reaction. J Am Chem Soc 129:9216–9221

Sansukcharearnpon A, Wanichwecharungruang S, Leepipatpaiboon N, Kerdcharoen T, Arayachukeat S (2010) High loading fragrance encapsulation based on a polymer-blend: preparation and release behavior. Int J Pharm 391:267–273

Chun YW, Al-Salami H, Dass CR (2017) Microparticles, microcapsules and microspheres: a review of recent developments and prospects for oral delivery of insulin. Int J Pharm 537:223–244

Dardelle G, Jacquemond M, Erni P (2017) Delivery systems for low molecular weight Payloads: core/shell capsules with composite coacervate/polyurea membranes. Adv Mater 29:6099–6105

Koh E, Kim NK, Shin J, Kim YW (2014) Polyurethane microcapsules for self-healing paint coatings. Rsc Advances 4:16214–16,223

Soto-Portas M L, Argillier J F, Méchin F, Zydowicz N (2003) Preparation of oily core polyamide microcapsules via interfacial polycondensation. Polym Int 52:522–527

Brown EN, Kessler MR, Sorros NR, White SR (2003) In situ poly(urea-formaldehyde) microencapsulation of dicyclopentadiene. J Microencapsulation 20:719–730

Tong XM, Zhang T, Yang MZ, Zhang Q (2010) Preparation and characterization of novel melamine modified poly(urea–formaldehyde) self-repairing microcapsules. Colloids Surf A Physicochem Eng Asp 371:91–97

Huang YI, Cheng YH, Yu CC, Tsai TR, Cham TM (2007) Microencapsulation of extract containing shikonin using gelatin–acacia coacervation method: a formaldehyde-free approach. Colloids Surf B Biointerfaces 58:290–297

Pitalua E, Jimenez M, Vernon-Carter EJ, Beristain CI (2010) Antioxidative activity of microcapsules with beetroot juice using gum Arabic as wall material. Food Bioprod Process 88:253–258

Prakash K, Raju PN, Shanta KK, Lakshmi MN (2007) Preparation and characterization of lamivudine microcapsules using various cellulose polymers. Trop J Pharm Res 6:841–847

Wei ZJ, Wang CY, Zou SW, Liu H, Tong Z (2012) Chitosan nanoparticles as particular emulsifier for preparation of novel pH-responsive Pickering emulsions and PLGA microcapsules. Polymer 53:1229–1235

Yoo SH, Song YB, Chang PS, Lee HG (2006) Microencapsulation of α-tocopherol using sodium alginate and its controlled release properties. Int J Biol Macromol 38:25–30

Calvo-Flores FG, Dobado JA (2010) Lignin as renewable raw material. Chemsuschem 3:1227–1235

Upton BM, Kasko AM (2016) Strategies for the Conversion of Lignin to High-Value Polymeric Materials: Review and Perspective. Chem Rev. 116:2275–2306

Zakzeski J, Bruijnincx PCA, Jongerius AL, Weckhuysen BM (2010) The catalytic valorization of lignin for the production of renewable chemicals. Chem Rev. 110:3552–3599

Dizhbite T, Telysheva G, Jurkjane V, Viesturs U (2004) Characterization of theradical scavenging activity of lignins-natural antioxidants. Bioresour Technol 95:309–317

Pan XJ, Kadla JF, Ehara K, Gilkes N, Saddler JN (2006) Organosolv ethanol lignin from hybrid poplar as a radical scavenger: relationship between lignin structure, extraction conditions, and antioxidant activity. J Agric Food Chem 54:5806–5813

Domenek S, Louaifi A, Guinault A, Baumberger S (2013) Potential of lignins as antioxidant additive in active biodegradable packaging materials. J Polym Environ 21:692–701

Strong L, Brown TA (1987) Avermectins in insect control and biology: a review. Bull Entomol Res 77:357–389

Manju S, Sreenivasan K (2011) Hollow microcapsules built by layer by layer assembly for the encapsulation and sustained release of curcumin. Colloids Surf B 2:588–593

Mariarosaria T, Francesca C, Pasquale M, Flavia C, Federica M (2014) Claudia CrestiniUltrasound driven assembly of lignin into microcapsules for storage and delivery of hydrophobic molecules. Biomacromolecules 15:1634–1643

Deng Y, Zhao H, Qian Y, Lü L, Wang B, Qiu X (2016) Hollow lignin azo colloids encapsulated avermectin with high anti-photolysis and controlled release performance. Ind Crops Prod 87:191–197

Li Y, Zhou M, Pang Y, Qiu X (2017) Lignin-based microsphere: preparation and performance on encapsulating the pesticide avermectin. ACS Sustainable Chem Eng 5:3321–3328

Liu ZQ, Qie R, Li W, Hong NL, Li Y, Li C, Wang RJ, Shi YL, Guo XH, Jia X (2017) Preparation of avermectin microcapsules with anti-photodegradation and slow-release by the assembly of lignin derivatives. New J Chem 41:3190–3195

Pang YX, Li X, Wang SW, Qiu XQ, Yang DJ, Lou HM (2018) Lignin-polyurea microcapsules with anti-photolysis and sustained-release performances synthesized via pickering emulsion template. React Funct Polym 123:115–121

Pang YX, Wang SW, Qiu XQ, Luo Y, Lou HM, Huang J (2017) Preparation of Lignin/Sodium Dodecyl Sulfate Composite Nanoparticles and Their Application in Pickering Emulsion Template-Based Microencapsulation. J Agric Food Chem 65:11011–11019

Qian Y, Deng Y, Qiu X, Li H, Yang D (2014) Formation of uniform colloidal spheres from lignin, a renewable resource recovered from pulping spent liquor. Green Chem 16:2156–2163

Paunov VN, Cayre OJ, Noble PF, Stoyanov SD, Velikov KP, Golding M (2007) Emulsions stabilised by food colloid particles: Role of particle adsorption and wettability at the liquid interface. J Colloid Interface Sci 312:381–389

Williams JM, Gray AJ, Wilkerson MH (1990) Emulsion stability and rigid foams from styrene or divinylbenzene water-in-oil emulsions. Langmuir 6:437–444

Davidson RS, Dunn LA, Castellan A, Nourmamode A (1991) A study of the photobleaching and photoyellowing of paper containing lignin using fluorescence spectroscopy. J Photochem Photobiol A 58:349–359

Ago M, Huan S, Borghei M, Raula J, Kauppinen EI, Rojas OJ (2016) High-Throughput Synthesis of Lignin Particles (∼30 nm to ∼2 μm) via Aerosol Flow Reactor: Size Fractionation and Utilization in Pickering Emulsions. ACS Appl Mater Interfaces 8:23302–23310

Acknowledgments

This study is financially supported by the National Natural Science Foundation of China (21878112, 21676109), Science and Technology Program of Guangdong (2017B090903003), National Natural Science Foundation of Guangdong (2017A030308012), and Guangdong Provincial Special Fund for Modern Agriculture Industry Technology Innovation Teams (2019KJ140).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pang, Y., Qin, Z., Wang, S. et al. Preparation and application performance of lignin-polyurea composite microcapsule with controlled release of avermectin. Colloid Polym Sci 298, 1001–1012 (2020). https://doi.org/10.1007/s00396-020-04664-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-020-04664-x