Abstract

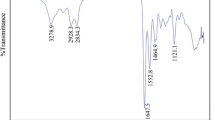

A novel amino-terminated hyperbranched polymer (ATHBP) was synthesized through the end-capping reaction between hyperbranched polymer with hydroxyl group (HBPH) and diethylenetriamine. The chemical structure of ATHBP was characterized by attenuated total internal reflectance infrared spectroscopy (ATR-IR) and 1H nuclear magnetic resonance spectroscopy (1H NMR). The effect of ATHBP content (0–30 wt%) on the impact resistance and glass transition temperature (Tg) of diglycidyl ether of bisphenol-A epoxy resin was studied. The toughness mechanism was discussed by observing the fracture surface morphologies of epoxy thermosets using field emission scanning electron microscopy (FESEM). The results showed that the degree of branching of ATHBP was 0.56. And the introduction of ATHBP could favorably improve the impact strength but not sacrifice the Tg of epoxy resin. For example, the impact strength of 25 wt% formulation was 60.7 % higher than that of the neat epoxy thermoset. FESEM analysis indicated that the toughening mechanism may be attributed to plastic deformation mechanism.

Similar content being viewed by others

References

Shieh JY, Ho TH, Wang CS (1995) Aminosiloxane-modified epoxy resins as microelectronic encapsulants. Die Angewandte Makromolekulare Chemie 224(1):21–32

Jose J, Joseph K, Pionteck J, Thomas S (2000) PVT behavior of thermoplastic poly(styrene-co-acrylonitrile)-modified epoxy systems: relating polymerization-induced viscoelastic phase separation with the cure shrinkage performance. J Phys Chem B 112(47):14793–14803

Iji M, Kiuchi Y, Soyama M (2003) Flame retardancy and heat resistance of phenol-biphenylene-type epoxy resin compound modified with benzoguanamine. Polyme Advan Technol 14(9):638–644

Jin F-L, Park S-J (2008) Fracture toughness of difunctional epoxy resin/thermally latent initiator system modified with polyesters. J Ind Eng Chem 14(5):564–567

Sinh LH, Son BT, Trung NN, Lim D-G, Shin S, Bae J-Y (2012) Improvements in thermal, mechanical, and dielectric properties of epoxy resin by chemical modification with a novel amino-terminated liquid-crystalline copoly(ester amide). React Funct Polym 72(8):542–548

Wang Y, Jing X (2007) Preparation of polystyrene/polyaniline core/shell structured particles and their epoxy-based conductive composites. Polymer Int 56(1):126–131

Meng Y, Zhang X-H, Du B-Y, Zhou B-X, Zhou X, Qi G-R (2011) Thermosets with core–shell nanodomain by incorporation of core crosslinked star polymer into epoxy resin. Polymer 52(2):391–399

Okamatsu T, Ochi M (2002) Effect on the toughness and adhesion properties of epoxy resin modified with silyl-crosslinked urethane microsphere. Polymer 43(3):721–730

Abadyan M, Kouchakzadeh MA, Bagheri R (2012) Fracture toughness of a hybrid rubber modified epoxy. II. Effect of loading rate. J Appl Polymer Sci 125(3):2476–2483

Abadyan M, Bagheri R, Kouchakzadeh MA (2012) Fracture toughness of a hybrid-rubber-modified epoxy. I. Synergistic toughening. J Appl Polymer Sci 125(3):2467–2475

RS Drake, DR Egan, and WT Murphy 1983 Elastomer-modified epoxy resins in coatings applications, in Epoxy resin chemistry II. Am Chem Soc, p 1–20

Balakrishnan S, Raghavan D (2003) Chemically functionalized clay epoxy nanocomposites for aerospace applications. Nanotech 3 2003 p:250–253

Tripathi G, Srivastava D (2009) Toughened cycloaliphatic epoxy resin for demanding thermal applications and surface coatings. J Appl Polymer Sci 114(5):2769–2776

Azeez AA, Rhee KY, Park SJ, Hui D (2013) Epoxy clay nanocomposites—processing, properties and applications: a review. Compos Part B-Eng 45(1):308–320

Zhou W, Cai J (2012) Mechanical and dielectric properties of epoxy resin modified using reactive liquid rubber (HTPB). J Appl Polymer Sci 124(5):4346–4351

Thomas R, Durix S, Sinturel C, Omonov T, Goossens S, Groeninckx G, Moldenaers P, Thomas S (2007) Cure kinetics, morphology and miscibility of modified DGEBA-based epoxy resin—effects of a liquid rubber inclusion. Polymer 48(6):1695–1710

Thomas R, Sinturel C, Pionteck J, Puliyalil H, Thomas S (2000) In-situ cure and cure kinetic analysis of a liquid rubber modified epoxy resin. Ind Eng Chem Res 51(38):12178–12191

Tao Q, Gan W, Yu Y, Wang M, Tang X, Li S (2004) Viscoelastic effects on the phase separation in thermoplastics modified cyanate ester resin. Polymer 45(10):3505–3510

Fernández B, Corcuera MA, Marieta C, Mondragon I (2001) Rheokinetic variations during curing of a tetrafunctional epoxy resin modified with two thermoplastics. Eur Polymer J 37(9):1863–1869

Gan W, Yu Y, Wang M, Tao Q, Li S (1984) Viscoelastic effects on the phase separation in thermoplastics-modified epoxy resin. Macromolecules 36(20):7746–7751

Larrañaga M, Martín MD, Gabilondo N, Kortaberria G, Corcuera MA, Riccardi CC, Mondragon I (2004) Cure kinetics of epoxy systems modified with block copolymers. Polym Int 53(10):1495–1502

S He, X Wang, X Guo, K Shi, Z Du and B Zhang. Studies of the properties of a thermosetting epoxy modified with block copolymers. Polym Int 2005 54(11):1543–1548

K de la Caba, M Larrañaga, A Eceiza, MA Corcuera and I Mondragon. Kinetics and morphology of an epoxy resin modified with PEO-PPO-PEO block copolymers. Macromol Symp 2006 239(1):30–35

Larrañaga M, Serrano E, Martin MD, Tercjak A, Kortaberria G, de la Caba K, Riccardi CC, Mondragon I (2007) Mechanical properties–morphology relationships in nano−/microstructured epoxy matrices modified with PEO–PPO–PEO block copolymers. Polym Int 56(11):1392–1403

Liu J, Sue H-J, Thompson ZJ, Bates FS, Dettloff M, Jacob G, Verghese N, Pham H (2009) Strain rate effect on toughening of nano-sized PEP–PEO block copolymer modified epoxy. Acta Mater 57(9):2691–2701

Serrano E, Kortaberria G, Arruti P, Tercjak A, Mondragon I (2009) Molecular dynamics of an epoxy resin modified with an epoxidized poly(styrene–butadiene) linear block copolymer during cure and microphase separation processes. Eur Polym J 45(4):1046–1057

MT Bashar, U Sundararaj and P Mertiny. Morphology and mechanical properties of nanostructured acrylic tri-block-copolymer modified epoxy. Polymer Engineering & Science 2013:n/a-n/a

Kim J-W, Kim J-Y, Suh K-D (1997) Preparation and physical properties of rubber-modified epoxy resin using poly(urethane acrylate)/poly(glycidyl methacrylate-co-acrylonitrile) core-shell composite particles. J Appl Polym Sci 63(12):1589–1600

Naguib M, Grassini S, Sangermano M (2013) Core/shell PBA/PMMA-PGMA nanoparticles to enhance the impact resistance of UV-cured epoxy systems. Macromol Mater Eng 298(1):106–112

Sato E, Uehara I, Horibe H, Matsumoto A (2014) One-step synthesis of thermally curable hyperbranched polymers by addition–fragmentation chain transfer using divinyl monomers. Macromolecules 47(3):937–943

Oh JH, Jang J, Lee S-H (2001) Curing behavior of tetrafunctional epoxy resin/hyperbranched polymer system. Polymer 42(20):8339–8347

Ratna D, Simon GP (2001) Thermomechanical properties and morphology of blends of a hydroxy-functionalized hyperbranched polymer and epoxy resin. Polymer 42(21):8833–8839

Ratna D, Becker O, Krishnamurthy R, Simon GP, Varley RJ (2003) Nanocomposites based on a combination of epoxy resin, hyperbranched epoxy and a layered silicate. Polymer 44(24):7449–7457

Foix D, Serra A, Amparore L, Sangermano M (2012) Impact resistance enhancement by adding epoxy ended hyperbranched polyester to DGEBA photocured thermosets. Polymer 53(15):3084–3088

Tomuta A, Ferrando F, Serra À, Ramis X (2012) New aromatic–aliphatic hyperbranched polyesters with vinylic end groups of different length as modifiers of epoxy/anhydride thermosets. React Funct Polym 72(9):556–563

Li S, Cui C, Hou H (2015) Synthesis and characterization of amino-terminated hyperbranched polymer and as modifier for epoxy resin thermosets. Colloid Polym Sci 293(9):2681–2688

Li S, Cui C, Hou H (2015) Synthesis of core-shell particles based on hyperbranced polyester and zirconium slag nanoparticles and Its influence on the impact resistance of epoxy resin thermosets. Polym Compos. doi:10.1002/pc.23602

Li S, Cui C, Hou H, Wu Q, Zhang S (2015) The effect of hyperbranched polyester and zirconium slag nanoparticles on the impact resistance of epoxy resin thermosets. Compos Part B 79:342–350

Hawker CJ, Lee R, Frechet JMJ (1991) One-step synthesis of hyperbranched dendritic polyesters. J Am Chem Soc 113(12):4583–4588

Jena KK, Raju KVSN, Prathab B, Aminabhavi TM (2007) Hyperbranched polyesters: synthesis, characterization, and molecular simulations. J Phys Chem B 111(30):8801–8811

Allauddin S, Akhil Chandran MK, Jena KK, Narayan R, Raju KVSN (2013) Synthesis and characterization of APTMS/melamine cured hyperbranched polyester-epoxy hybrid coatings. Progress in Organic Coatings 76(10):1402–1412

Barua S, Dutta G, Karak N (2013) Glycerol based tough hyperbranched epoxy: synthesis, statistical optimization and property evaluation. Chem Eng Sci 95(0):138–147

Lv J, Meng Y, He L, Qiu T, Li X, Wang H (2013) Novel epoxidized hyperbranched poly(phenylene oxide): synthesis and application as a modifier for diglycidyl ether of bisphenol A. J Appl Polym Sci 128(1):907–914

Chen S, Feng J (2014) Epoxy laminated composites reinforced with polyethyleneimine functionalized carbon fiber fabric: mechanical and thermal properties. Compos Sci Technol 101:145–151

Buonocore GG, Schiavo L (2013) I Attianese and A Borriello. Hyperbranched polymers as modifiers of epoxy adhesives. Compos Part B 53(0):187–192

Acknowledgments

This study was funded by the National Natural Science Foundation of China (grant number 51202211, 51402251, 51578289, and 51502259), the National Science and Technology Major Project of the Ministry of Science and Technology of China (grant number 2012ZX04010032), the Natural science fund of Jiangsu Province (grant number BK20130428), the joint research fund between Collaborative Innovation Center for Ecological Building Materials and Environmental Protection Equipments and Key Laboratory for Advanced Technology in Environmental Protection of Jiangsu Province (grant number GX2015107), a project funded by the Flagship Major Development of Jiangsu Higher Education Institutions (grant number PPZY2015A025), and the Research fund of Key Laboratory for Advanced Technology in Environmental Protection of Jiangsu Province (grant number AE201111).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Li, S., Zhu, H., Lv, T. et al. The effect of amino-terminated hyperbranched polymers on the impact resistance of epoxy resins. Colloid Polym Sci 294, 607–615 (2016). https://doi.org/10.1007/s00396-015-3811-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-015-3811-5