Abstract

In this study, the hierarchical crystalline structures of high-density polyethylene (HDPE) samples molded by gas-assisted injection molding (GAIM) with different gas cooling times were characterized via scanning electron microscopy, two-dimensional wide-angle X-ray scattering, tensile testing techniques, and differential scanning calorimetry, respectively. It was found that the shish-kebab, the oriented lamellae, and common spherulite structures orderly distributed from the skin region to gas channel region of samples. More importantly, the wider area with highly oriented structure (shish-kebab) was obtained in the samples with longer gas cooling time, in that the longer gas cooling time tends to increase the cooling rate of polymer melt, and then much more stretched chains are retained. Although lower crystallinity, the higher degree of orientation, and much more shish-kebab structures lead to significant reinforcement from 28 to 785 MPa of the samples with gas cooling time of 0.5 s to 32 and 879 MPa of the samples with gas cooling time of 20 s for tensile strength and modulus, respectively. Finally, combined the HDPE molecular parameter with characteristic of the GAIM temperature field and flow field, the formation and stability of crystalline morphology in different regions of sample were discussed.

Similar content being viewed by others

References

Somani RH, Yang L, Zhu L, Hsiao BS (2005) Flow-induced shish-kebab precursor structures in entangled polymer melts. Polymer 46(20):8587–8623

Mykhaylyk OO, Chambon P, Impradice C, Fairclough JPA, Terrill NJ, Ryan AJ (2010) Control of structural morphology in shear-induced crystallization of polymers. Macromolecules 43(5):2389–2405

Sousa R, Reis R, Cunha A, Bevis M (2003) Structural development of HDPE in injection molding. J Appl Polym Sci 89(8):2079–2087

Pennings A, Kiel A (1965) Fractionation of polymers by crystallization from solution III. On the morphology of fibrillar polyethylene crystals grown in solution. Colloid Polym Sci 205(2):160–162

Kumaraswamy G, Kornfield JA, Yeh F, Hsiao BS (2002) Shear-enhanced crystallization in isotactic polypropylene. 3. Evidence for a kinetic pathway to nucleation. Macromolecules 35(5):1762–1769

Azzurri F, Alfonso GC (2005) Lifetime of shear-induced crystal nucleation precursors. Macromolecules 38(5):1723–1728

Yang H-R, Lei J, Li L, Fu Q, Li Z-M (2012) Formation of interlinked shish-kebabs in injection-molded polyethylene under the coexistence of lightly cross-linked chain network and oscillation shear flow. Macromolecules 45(16):6600–6610

Kanaya T, Matsuba G, Ogino Y, Nishida K, Shimizu HM, Shinohara T, Oku T, Suzuki J, Otomo T (2007) Hierarchic structure of shish-kebab by neutron scattering in a wide Q range. Macromolecules 40(10):3650–3654

Balzano L, Rastogi S, Peters GW (2008) Flow induced crystallization in isotactic polypropylene-1, 3: 2, 4-bis (3, 4-dimethylbenzylidene) sorbitol blends: implications on morphology of shear and phase separation. Macromolecules 41(2):399–408

Kimata S, Sakurai T, Nozue Y, Kasahara T, Yamaguchi N, Karino T, Shibayama M, Kornfield JA (2007) Molecular basis of the shish-kebab morphology in polymer crystallization. Science 316(5827):1014–1017

Kalay G, Bevis MJ (1997) The effect of shear controlled orientation in injection moulding on the mechanical properties of an aliphatic polyketone. J Polym Sci, Part B: Polym Phys 35(3):415–430

Silva CA, Viana JC, Cunha AM (2007) Novel morphologies produced by active shear rotation during injection molding. Macromol Mater Eng 292(5):655–665

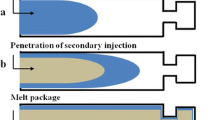

Avery J (2001) Gas-assist injection molding: principles and applications. Hanser, Munich

Li C, Isayev A (2004) Primary and secondary gas penetration during gas‐assisted injection molding Part I: formulation and modeling. Polym Eng Sci 44(5):983–991

Li C, Shin J, Isayev A, Lee H (2004) Primary and secondary gas penetration during gas‐assisted injection molding Part II: simulation and experiment. Polym Eng Sci 44(5):992–1002

Zhou H, Li D (2003) Further studies of the gas penetration process in gas‐assisted injection molding. Polym-Plast Technol Eng 42(5):911–923

Turng L (1995) Development and application of CAE technology for the gas‐assisted injection molding process. Adv Polym Technol 14(1):1–13

Gao D, Nguyen K, Garcia-Rejon A, Salloum G (1997) Optimization of the gas-assisted injection moulding process using multiple gas-injection systems. J Mater Process Technol 69(1):282–288

Ilinca F, Hétu JF (2002) Three‐dimensional finite element solution of gas‐assisted injection moulding. Int J Numer Methods Eng 53(8):2003–2017

Chen S, Cheng N, Hsu K (1995) Simulation and verification of the secondary gas penetration in a gas-assisted-injection molded spiral tube. Int Commun Heat Mass Transfer 22(3):319–328

Chen S, Hsu K, Hsu K (1995) Analysis and experimental study of gas penetration in a gas‐assisted injection‐molded spiral tube. J Appl Polym Sci 58(4):793–799

Der Chien R, Chen S-C, Kang Y, Yeh H-Y (1998) Effect of gas channel design on bending properties of gas-assisted injection molded polystyrene parts. J Reinf Plast Compos 17(13):1213–1230

Chien RD, Chen CS, Chen SC, Yeh HY, Huang DK (1999) Correlation of gas penetration and permeation to the structural performance of gas‐assisted injection‐molded parts. Adv Polym Technol 18(4):303–313

Chen SC, Hu SY, Chien RD, Jeng MC (1999) Analyses and measurements on bending performance of gas‐assisted injection molded parts. Adv Polym Technol 18(1):1–9

Zheng GQ, Yang W, Yang MB, Chen JB, Li Q, Shen CY (2008) Gas‐assisted injection molded polypropylene: the skin–core structure. Polym Eng Sci 48(5):976–986

Zheng G, Yang W, Liu C, Yang M, Chen J, Li Q, Shen C (2008) Transcrystallinity in a polycarbonate (PC)/polyethylene (PE) blend prepared by gas-assisted injection molding: a new understanding of its formation mechanism. J Macromol Sci, Part B 47(5):829–836

Wang L, Yang B, Yang W, Sun N, Yin B, Feng J-M, Yang M-B (2011) Morphology and mechanical property of high-density polyethylene parts prepared by gas-assisted injection molding. Colloid Polym Sci 289(15–16):1661–1671

Wang L, Yang B, Sun N, Zhang K, Feng J-M, Yang M-B (2012) Role of gas delay time on the hierarchical crystalline structure and mechanical property of HDPE molded by gas-assisted injection molding. Colloid Polym Sci 290(12):1133–1144

Zheng G-Q, Huang L, Yang W, Yang B, Yang M-B, Li Q, Shen C-Y (2007) Hierarchical crystalline structure of HDPE molded by gas-assisted injection molding. Polymer 48(19):5486–5492

Yang B, Fu XR, Yang W, Liang SP, Hu S, Yang MB (2009) Simulation of phase‐change heat transfer during cooling stage of gas‐assisted injection molding of high‐density polyethylene via enthalpy transformation approach. Polym Eng Sci 49(6):1234–1242

Yang B, Fu XR, Yang W, Liang SP, Sun N, Hu S, Yang MB (2009) Effect of melt and mold temperatures on the solidification behavior of HDPE during gas‐assisted injection molding: an enthalpy transformation approach. Macromol Mater Eng 294(5):336–344

Balzano L, Rastogi S, Peters G (2011) Self-nucleation of polymers with flow: the case of bimodal polyethylene. Macromolecules 44(8):2926–2933

Dealy JM, Larson RG (2006) Structure and rheology of molten polymers: from structure to flow behavior and back again. Hanser, Munich

Balzano L, Cavallo D, Van Erp TB, Ma Z, Housmans J-W, Fernandez-Ballester L, Peters GW. Dynamics of fibrillar precursors of shishes as a function of stress. In: IOP Conference Series: Materials Science and Engineering, 2010. vol 1. IOP Publishing, p 012005

Hu S, Yang W, Liang S-P, Yang B, Yang M-B (2009) Simulation of gas-assisted injection molding of high-density polyethylene: the role of rheological properties and physical fields on the crystalline morphology. J Macromol Sci, Part B 48(6):1201–1211

Zheng G-Q, Yang W, Huang L, Li Z-M, Yang M-B, Yin B, Li Q, Liu C-T, Shen C-Y (2007) The role of gas penetration on morphological formation of polycarbonate/polyethylene blend molded by gas-assisted injection molding. J Mater Sci 42(17):7275–7285

Keller A, Cheng SZD (1998) The role of metastability in polymer phase transitions. Polymer 39(19):4461–4487. doi:10.1016/s0032-3861(97)10320-2

Picken SJ, Aerts J, Visser R, Northolt MG (1990) Structure and rheology of aramid solutions: X-ray scattering measurements. Macromolecules 23(16):3849–3854

Zhu P-W, Edward G (2008) Orientational distribution of parent–daughter structure of isotactic polypropylene: a study using simultaneous synchrotron WAXS and SAXS. J Mater Sci 43(19):6459–6467

Schrauwen B, Lv B, Spoelstra A, Govaert L, Peters G, Meijer H (2004) Structure, deformation, and failure of flow-oriented semicrystalline polymers. Macromolecules 37(23):8618–8633

Su R, Jiang K, Ge Y, Hu S, Li Z, Li X, Wang K, Zhang Q, Fu Q, Yang F (2011) Shear‐induced fibrillation and resultant mechanical properties of injection‐molded polyamide 1010/isotactic polypropylene blends. Polym Int 60(11):1655–1662

Na B, Zhang Q, Wang Y, Fu Q (2004) Orientation effects on the deformation and fracture properties of high‐density polyethylene/ethylene vinyl acetate (HDPE/EVA) blends. Polym Int 53(8):1078–1086

Na B, Wang K, Zhang Q, Du R, Fu Q (2005) Tensile properties in the oriented blends of high-density polyethylene and isotactic polypropylene obtained by dynamic packing injection molding. Polymer 46(9):3190–3198

Acknowledgments

The authors gratefully acknowledge the financial support of National Natural Science Foundation of China (grant no. 21174092 and 51121001). The authors are also indebted to Mr. Chao-Liang Zhang from the Huaxi College of Stomatology, Sichuan University, for his kind assistance in morphological observations. In particular, Mr. Guo-qiang pan from the National Synchrotron Radiation Laboratory, University of Science and Technology of China, is gratefully acknowledged for the 2d-WAXS measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, XC., Zhang, QP., Wang, L. et al. Role of gas cooling time on crystalline morphology and mechanical property of the HDPE parts prepared by gas-assisted injection molding. Colloid Polym Sci 292, 1129–1142 (2014). https://doi.org/10.1007/s00396-013-3152-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-013-3152-1