Abstract

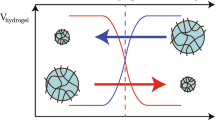

Microgels are deformable colloids that can be packed by external compression; such packing transforms a suspension of loose microgels into a viscoelastic paste with mechanical properties controlled by the elasticity of the constituent particles. We aim to understand how the presence of microgel particles with different individual elastic moduli affects this interplay in heterogeneous microgel packings. We do this by preparing microgel pastes that contain both soft, loosely cross-linked and stiff, densely cross-linked microgel particles and probe their shear elasticity. We consider particle packing fractions that cover the range from particles at the onset of contact to particles that are strongly packed, deformed, and deswollen to investigate the transition from a particulate suspension to a macrogel-type system. These studies reveal that the elasticity of heterogeneous microgel suspensions at low packing is due to the response of the soft, easily deformable microgel particles alone, whereas at high packing both soft and stiff microgels linearly add to the paste elasticity. This fundamental difference is due to the fundamentally different origin of elasticity at different microgel packing; whereas the soft particle interaction potential dominates the suspension mechanics at low microgel packing, rubber-like elasticity that equally reflects both soft and stiff contributions governs the mechanics of the same samples at high microgel packing.

Similar content being viewed by others

References

Funke W, Okay O, Joos-Muller B (1998) Microgels—intramolecularly crosslinked macromolecules with a globular structure. Adv Polym Sci 136:139–234

Heyes DM, Branka AC (2009) Interactions between microgel particles. Soft Matter 5:2681–2685

Fernandez-Nieves A, Fernandez-Barbero A, Vincent B, de las Nieves FJ (2003) Osmotic de-swelling of ionic microgel particles. J Chem Phys 119:10383–10388

Le Grand A, Petekidis G (2008) Effects of particle softness on the rheology and yielding of colloidal glasses. Rheol Acta 4:579–590

Senff H, Richtering W (1999) Temperature sensitive microgel suspensions: colloidal phase behavior and rheology of soft spheres. J Chem Phys 111:1705–1711

Seth JR, Cloitre M, Bonnecaze RT (2006) Elastic properties of soft particle pastes. J Rheol 50:353–376

Menut P, Seiffert S, Sprakel J, Weitz DA (2012) Does size matter? Elasticity of compressed suspensions of colloidal- and granular-scale microgels. Soft Matter 8:156–164

Cloitre M, Borrega R, Monti F, Leibler L (2003) Structure and flow of polyelectrolyte microgels: from suspensions to glasses. C R Physique 4:221–230

Wyart M (2011) Elasticity of soft particles and colloids near the jamming threshold. In: Fernandez-Nieves A, Wyss HM, Mattsson J, Weitz DA (eds) Microgel suspensions: fundamentals and applications. Wiley, Berlin, pp 195–206

Lietor-Santos J, Sierra-Martın B, Fernandez-Nieves A (2011) Bulk and shear moduli of compressed microgel suspensions. Phys Rev E Rap Comm 84:060402

Di Lorenzo F, Seiffert S (2013) Macro- and microrheology of heterogeneous microgel packings. Macromolecules 46:1962–1972

McPhee W, Tam KC, Pelton R (1993) Poly(N-isopropylacrylamide) latices prepared with sodium dodecyl sulfate. J Colloid Interface Sci 3:24–30

http://www.brocku.ca/researchers/peter_rand/osmotic/osfile.html

Meeker SP, Bonnecaze RT, Cloitre M (2004) Slip and flow in pastes of soft particles: direct observation and rheology. J Rheol 48:1295–1320

Seth JR, Cloitre M, Bonnecaze RT (2008) Influence of short-range forces on wall-slip in microgel pastes. J Rheol 52:1241–1268

Paulin SE, Ackerson BJ, Wolfe MS (1996) Equilibrium and shear induced nonequilibrium phase behavior of PMMA microgel spheres. J Colloid Interface Sci 178:251–262

Senff H, Richtering W, Nordhausen C, Weiss A, Ballauff M (1999) Rheology of a temperature sensitive core-shell latex. Langmuir 15:102–106

Koumakis N, Pamvouxoglou A, Poulosa AS, Petekidis G (2012) Direct comparison of the rheology of model hard and soft particle glasses. Soft Matter 8:4271–4284

Johnson KL (1985) Contact mechanics. Cambridge University Press, Cambridge

Flory PJ (1953) Principles of polymer chemistry. Cornell University Press, Ithaca

Stieger M, Richtering W, Pedersen JS, Lindner P (2004) Small-angle neutron scattering study of structural changes in temperature sensitive microgel colloids. J Chem Phys 120:6197–6206

Deen GR, Alsted T, Richtering W, Pedersen GS (2011) Synthesis and characterization of nanogels of poly(N-isopropylacrylamide) by a combination of light and small-angle X-ray scattering. Phys Chem Chem Phys 13:3108–3114

Scheffold F, Diaz-Leyva P, Reufer M, Braham NB, Lynch I, Harden JL (2010) Brushlike interactions between thermoresponsive microgel particles. Phys Rev Lett 104:128304

Romeo G, Pica Ciamarra N (2013) Elasticity of compressed microgel suspensions. Soft Matter 9:5401–5406

Lyon LA, Meng M, Singh N, Sorrell CD, St. John A (2009) Thermoresponsive microgel-based materials. Chem Soc Rev 38:865–874

Acknowledgments

This project was funded by the Focus Area NanoScale at FU Berlin, which is gratefully acknowledged. S. Seiffert is a Liebig Fellow of the Fund of the Chemical Industry (Germany). F. Di Lorenzo is a doctoral student of the Berlin-based Helmholtz Virtual Institute “Multifunctional Materials for Medicine”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Di Lorenzo, F., Seiffert, S. Particulate and continuum mechanics of microgel pastes: effect and non-effect of compositional heterogeneity. Colloid Polym Sci 291, 2927–2933 (2013). https://doi.org/10.1007/s00396-013-3032-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-013-3032-8