Abstract

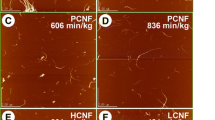

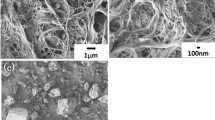

Optical microscopy and transmission electron microscopy have been used to investigate the morphology of polylactide (PLA)/microfibrillated cellulose (MFC) composites prepared by: compression molding of wet-comingled MFC and PLA latex or powder, twin-screw extrusion of the wet-comingled compounds, and solvent mixing of PLA with MFC or acetylated MFC. Compression molding of wet-comingled MFC and PLA latex or powder compounds resulted in a cellular MFC network, whereas solvent-cast films showed a more uniform dispersion of MFC fibers. Somewhat lower aggregate diameters observed in the acetylated MFC were assumed to be due to decreased MFC hydrophilicity and improved chemical affinity with the PLA matrix. The MFC networks in the commingled compounds were severely disrupted after twin-screw extrusion. This confirmed the limited deformability of the networks inferred from the extensive syneresis during the initial compression molding step, and accounted for substantial losses in stiffness reinforcement by the MFC after extrusion.

Similar content being viewed by others

References

Mohanty AK, Misra M, Hinrichsen G (2000) Biofibres, biodegradable polymers, and biocomposites: an overview. Macromol Mater Eng 276(277):1–24

Södergård A, Stolt M (2002) Properties of lactic acid-based polymers and their correlation with composition. Prog Polym Sci 27:1123–1163

Boldizar A, Klason C, Kubát J, Naslund P, Sáha P (1987) Prehydrolyzed cellulose as reinforcing filler for thermoplastics. Int J Polym Mater 11:229–262

Dufresne A, Vignon MR (1998) Improvement of starch film performances using cellulose microfibrils. Macromolecules 31:2693–2696

Mathew P, Oksman K, Sain M (2006) Mechanical properties of biodegradable composites from poly lactic acid (PLA) and microcrystalline cellulose (MCC). J Appl Polym Sci 97:2014–2025

Eichhorn S, Dufresne A, Aranguren M, Marcovich N, Capadona J, Rowan S, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito A, Mangalam A, Simonsen J, Benight A, Bismarck A, Berglund L, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci 37:815–827

Herrick FW, Casebier RL, Hamilton JK, Sandberg KR (1983) Microfibrillated cellulose: morphology and accessibility. J Appl Polym Sci 37:797–813

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941

Laivins GV, Scallan AM (1993) The mechanism of hornification of wood pulps. Proc 10th Fundamental Research Symposium, PIRA International, Oxford, UK: 1235–1260

Tingaut P, Zimmermann T, Lopez-Suevos F (2010) Synthesis and characterization of bionanocomposites with tunable properties from poly(lactic acid) and acetylated microfibrillated cellulose. Biomacromolecules 11:454–464

Suryanegara L, Nakagaito AN, Yano H (2009) The effect of crystallization of PLA on the thermal and mechanical properties of microfibrillated cellulose-reinforced PLA composites. Comp Sci Technol 69:1187–1192

Siqueria G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 10:425–432

Suryanegara L, Nakagaito AN, Yano H (2010) Thermo-mechanical properties of microfibrillated cellulose-reinforced partially crystallized PLA composites. Cellulose 17:771–778

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Iwatake, Nogi M, Yano H (2008) Cellulose nanofiber-reinforced polylactic acid. Comp Sci Technol 68:2103–2106

Zimmermann T, Pöhler E, Geiger T (2004) Cellulose fibrils for polymer reinforcement. Adv Eng Mater 6:754–761

Lu J, Drzal LT (2010) Microfibrillated cellulose/cellulose acetate composites: effect of surface treatment. J Polym Sci B Polym Phys 48:153–161

Nakagaito AN, Fujimura A, Sakai T, Hama Y, Yano H (2009) Production of microfibrillated cellulose (MFC)-reinforced polylactic acid (PLA) nanocomposites from sheets obtained by a papermaking-like process. Comp Sci Technol 69:1293–1297

Oksman K, Mathew AP, Bondeson D, Kvien I (2006) Manufacturing process of polylactic acid (PLA)—cellulose whiskers nanocomposites. Comp Sci Technol 66:2776–2784

Gardner DJ, Oporto GS, Mills R, Samir M (2008) Adhesion and surface issues in cellulose and nanocellulose. J Adhes Sci Technol 22:545–567

Henriksson M, Berglund LA (2007) Structure and properties of cellulose nanocomposite films containing melamine formaldehyde. J Appl Polym Sci 106:2817–2824

Halpin JC (1976) The Halpin–Tsai equations: a review. Polym Eng Sci 16:344–352

Boissard CIR (2012) Processing of sustainable cellular biocomposites. PhD Thesis: Ecole Polytechnique Fédérale de Lausanne

Plummer CJG, Ruggerone R, Negrete-Herrera N, Bourgeat-Lami E, Månson J-AE (2010) Small strain mechanical properties of latex-based nanocomposite films. Macromol Symp 294:1–10

Larsson K, Ankerfors M, Lindström T (2012) Properties of bionanocomposites made from poly(lactide) latex and microfibrillated cellulose. http://www.sustaincomp.eu/upload/16149/Karolina%20Larsson,%20Innventia_webb.pdf

Acknowledgments

This work was partially funded by the SustainComp project (grant no.214660) in the Seventh Research Framework Program (FP7) of the European Union (EU). The authors would like to express their thanks to Karolina Larsson and Mikael Ankerfors of Inventia, and Philippe Tingaut and Tanya Zimmermann of EMPA for providing materials and help with specimen preparation, and the Electron Microscopy Center (CIME) of the EPFL for technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Plummer, C.J.G., Choo, C.K.C., Boissard, C.I.R. et al. Morphological investigation of polylactide/microfibrillated cellulose composites. Colloid Polym Sci 291, 2203–2211 (2013). https://doi.org/10.1007/s00396-013-2968-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-013-2968-z